Tower signal lamp for light marking

A technology of signal lights and tower tubes, applied in the field of lighting, can solve problems such as failure of the overall protection ability of the tower wall, lack of night markings, difficulty in meeting requirements, etc., and achieve the effects of widely popularizing the use value, convenient operation and setting, and convenient calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

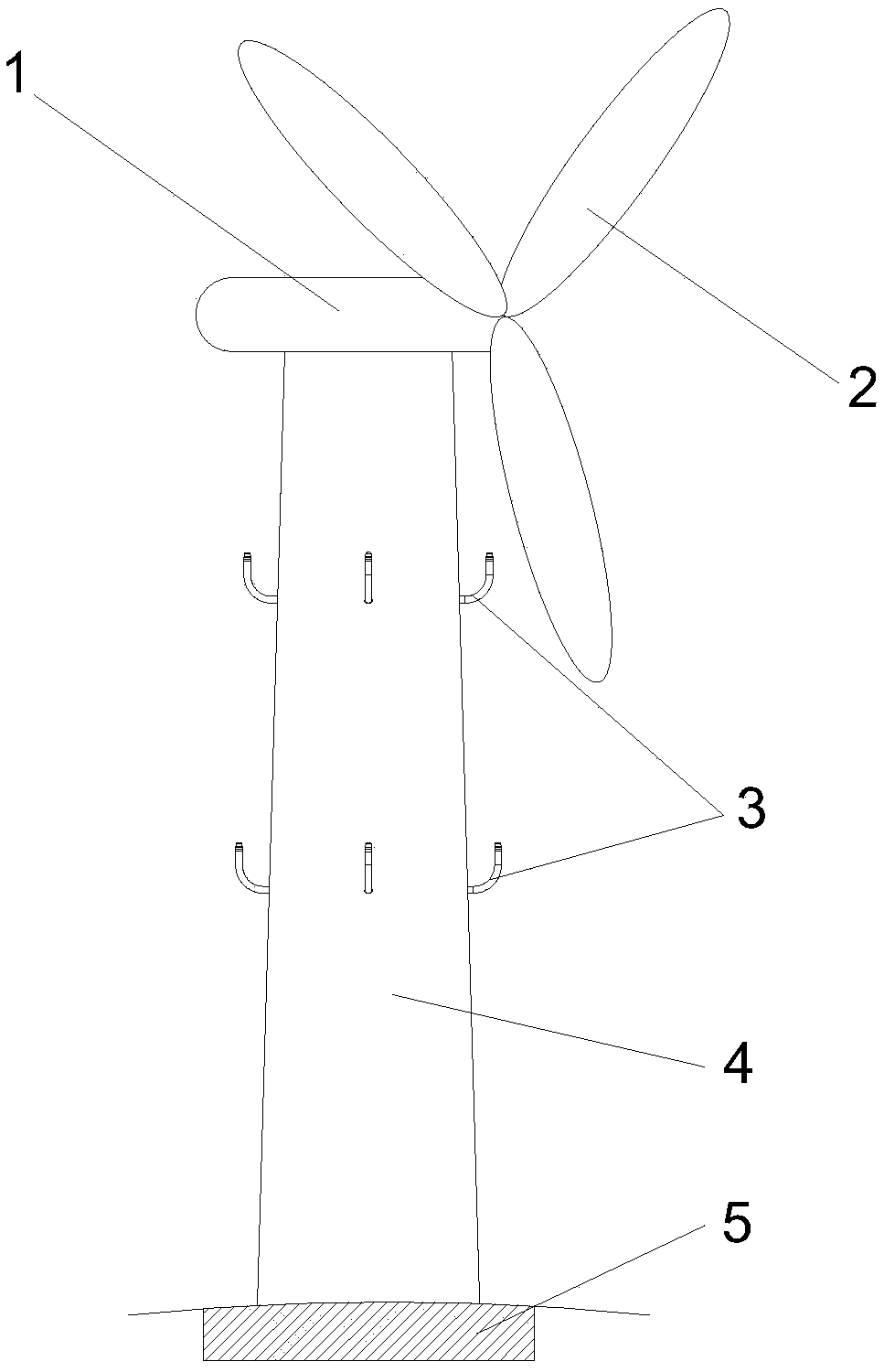

[0029] like figure 1 Shown is a schematic diagram of the overall structure of several tower tube signal lights of wind power equipment towers. The tower 4 is erected on the foundation 5, and the upper end of the tower tube 4 is provided with a mechanical pod 1 and blades 2 on the rotor arranged on the pod. Tower signal lights 3 are installed on the two tower planes of the tower tube 4, thereby playing a marking role for air traffic, so that the tower can be seen from a distance.

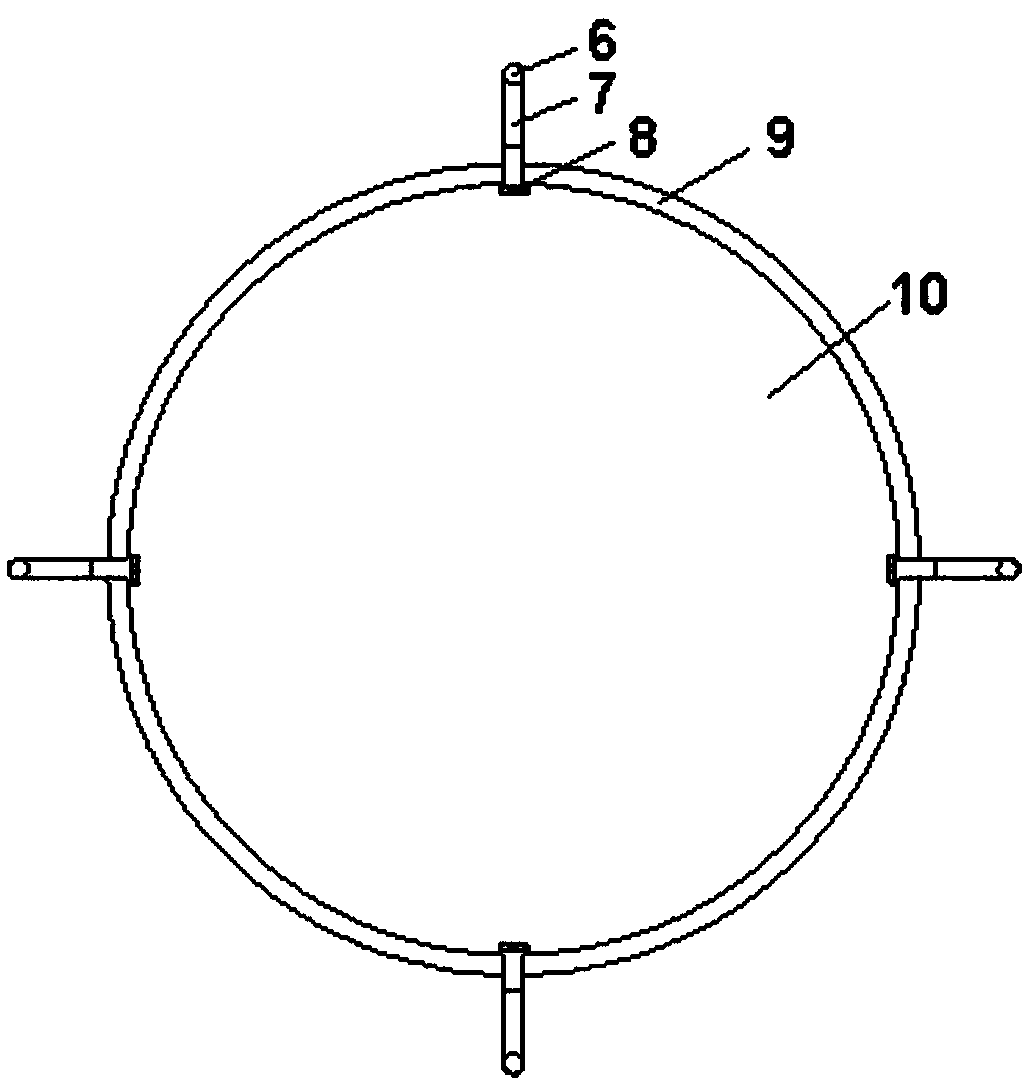

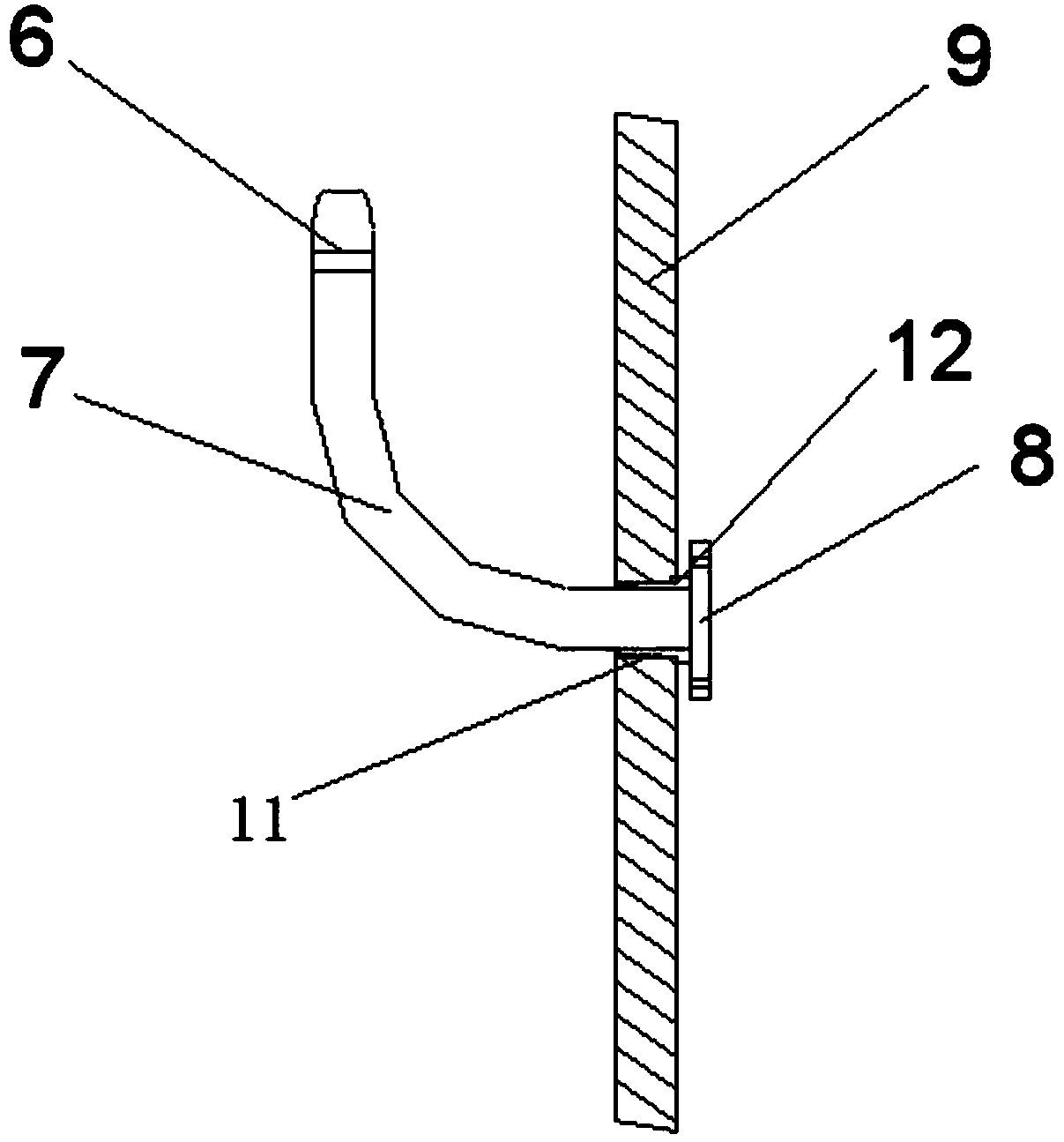

[0030] like Figure 2-4 As shown, a tower signal light for light marking of the present invention includes a right-angle elbow bracket 7, a light-emitting element 6 arranged at the first end of the right-angle elbow bracket 7, and an introduction of the second end of the right-angle elbow bracket 7. Wire wiring device (not shown in the figure); the tower wall 9 of the tower 4 is provided with a hole 11, and the right-angle elbow bracket 7 can be inserted from the tower inner wall to the tower outer ...

Embodiment 2

[0049] like Figure 2-4 As shown, a tower signal light for light marking of the present invention includes a right-angle elbow bracket 7, a light-emitting element 6 arranged at the first end of the right-angle elbow bracket 7, and an introduction of the second end of the right-angle elbow bracket 7. Wire wiring device (not shown in the figure); the tower wall 9 of the tower 4 is provided with a hole 11, and the right-angle elbow bracket 7 can be inserted from the tower inner wall to the tower outer wall through the hole 11 on the tower wall 9, and the right-angle elbow bracket The second end of 7 is fixed in the hole 11 of the tower wall 9; the light-emitting element 6 emits light to the periphery of the tower, the horizontal light-emitting angle reaches 360°, and the vertical light-emitting angle is >90°.

[0050] The tower signal lamp of the present invention is fixedly connected to the light-emitting element and the wiring device through the right-angle elbow bracket. The r...

Embodiment 3

[0066] like figure 1 Shown is a schematic diagram of the overall structure of several tower tube signal lights of wind power equipment towers. The tower 4 is erected on the foundation 5, and the upper end of the tower tube 4 is provided with a mechanical pod 1 and blades 2 on the rotor arranged on the pod. Tower signal lights 3 are installed on the two tower planes of the tower tube 4, thereby playing a marking role for air traffic, so that the tower can be seen from a distance.

[0067] like Figure 2-4 As shown, a tower signal light for light marking of the present invention includes a right-angle elbow bracket 7, a light-emitting element 6 arranged at the first end of the right-angle elbow bracket 7, and an introduction of the second end of the right-angle elbow bracket 7. Wire wiring device (not shown in the figure); the tower wall 9 of the tower 4 is provided with a hole 11, and the right-angle elbow bracket 7 can be inserted from the tower inner wall to the tower outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com