Smoke exhaust pipeline cleaning device

A technology for cleaning devices and smoke exhaust pipes, which is applied in the directions of cleaning hollow objects, cleaning methods and utensils, removing solid residues, etc. Pipeline smoke exhaust efficiency and other issues, to improve the convenience of cleaning, to avoid beams and columns, and to increase the efficiency of air purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

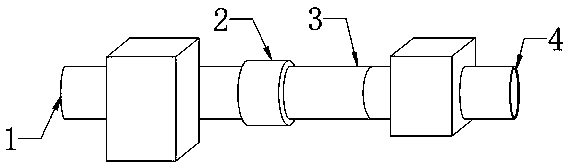

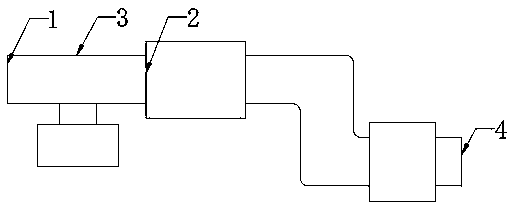

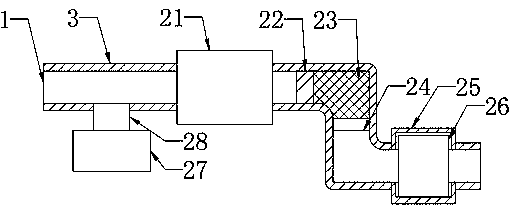

[0021] see Figure 1-Figure 3 , the present invention provides a technical solution: a cleaning device for a smoke exhaust pipeline, including a smoke inlet 1, a cleaning mechanism 2, a main body of the smoke exhaust pipeline 3 and a smoke outlet 4, and the smoke inlet 1 is set in the exhaust The left end surface of the smoke pipeline main body 3 and the right end surface of the smoke exhaust pipeline main body 3 are provided with a smoke outlet 4 , and the cleaning mechanism 2 is arranged on the annular side of the smoke exhaust pipeline main body 3 .

[0022] The cleaning mechanism 2 includes an oil-water separator 21, a filter screen 22, a drying box 23, an isolation net 24, an installation shell 25, a blower 26, a small electric steam generato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com