Building center flue system

A flue system, central technology, applied in the direction of oil fume removal, vertical pipes, household heating, etc., can solve the problems of low operating efficiency, shortened motor life, large smoke exhaust resistance, etc., to achieve high smoke exhaust efficiency and fan life Long, low smoke exhaust resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

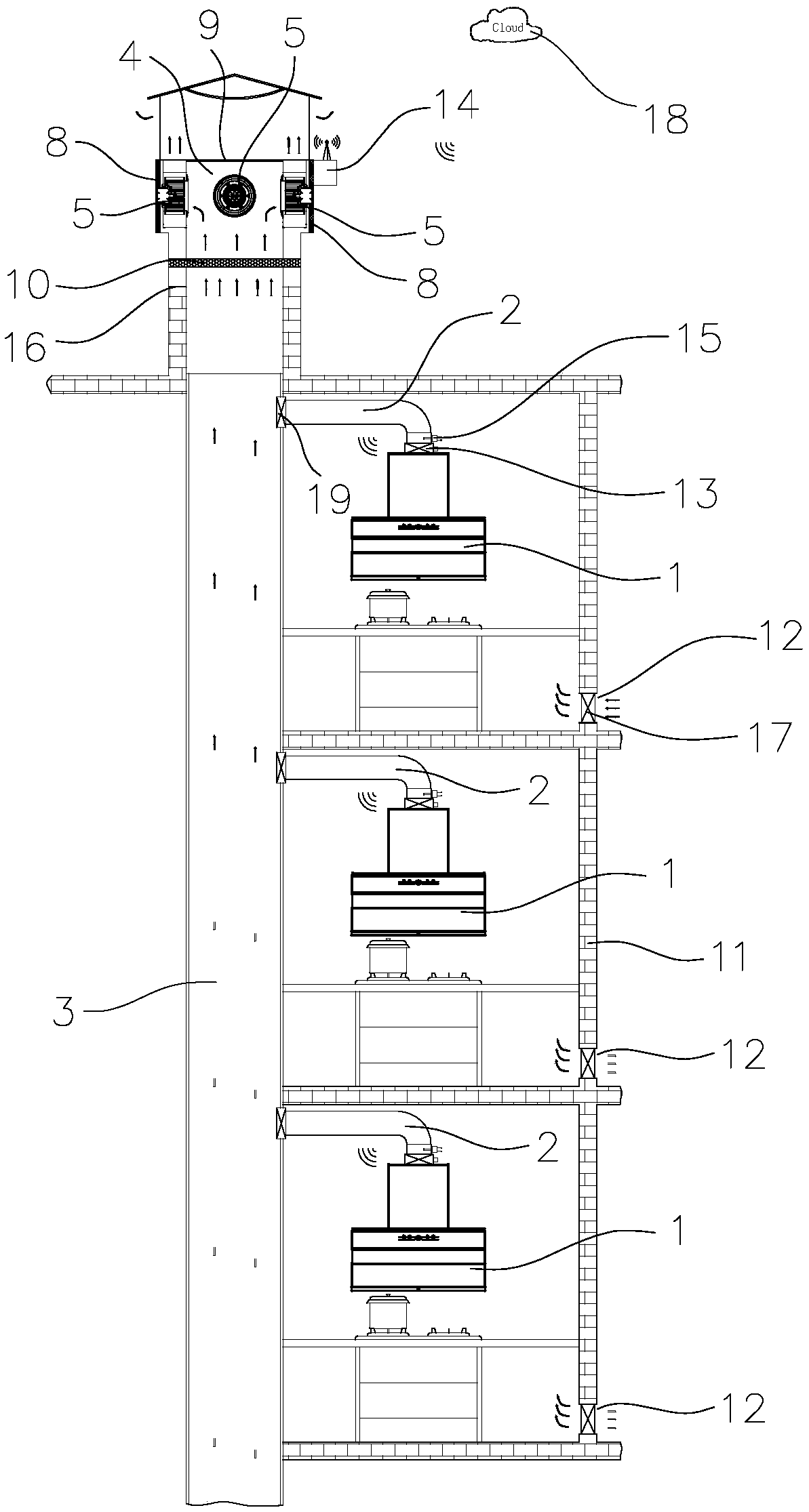

[0035] Such as Figure 1 to Figure 3 As shown, the central flue system of the building in this embodiment includes range hoods 1 installed on different floors, and the air outlets of each range hood 1 are connected with the public flue 3 through their respective smoke pipes 2. The air outlet channel 4 that is vertically connected with the outlet of the public flue 3 is installed, the aperture of the air outlet channel 4 is greater than the aperture of the public flue 3, and the flue fan 5 is located at a position close to the inner wall of the air outlet channel and avoids coming from the public air channel. The airflow discharged from the outlet of the flue 3, thereby reducing the smoke exhaust resistance of the system.

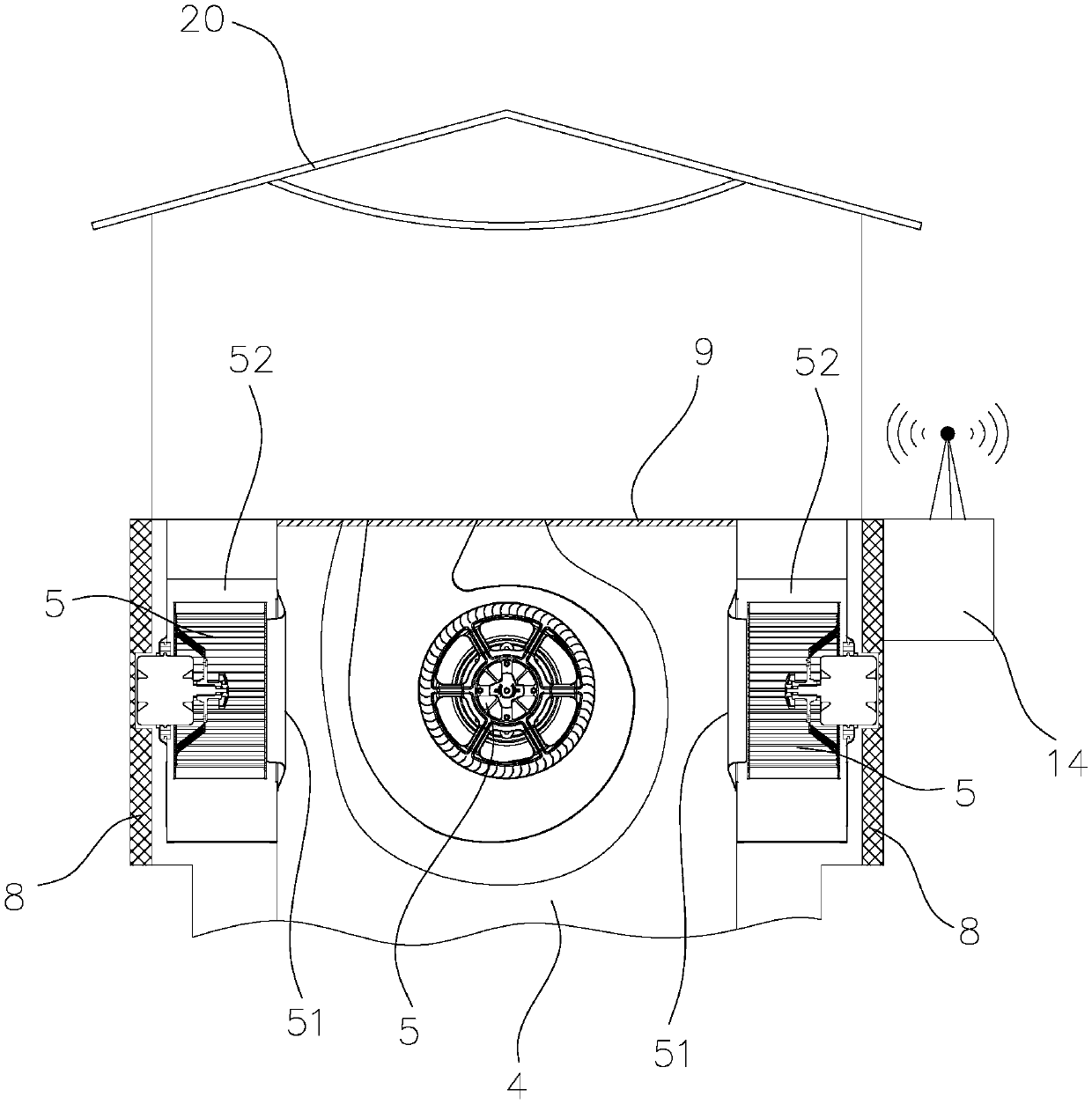

[0036] In this embodiment, the air outlet passage 4 is a square passage, and the flue fan 5 is a centrifugal fan placed vertically. The back of the flue fan 5 is close to the inner wall of the air outlet passage 4. A noise reduction and muffler device 8 is ...

Embodiment 2

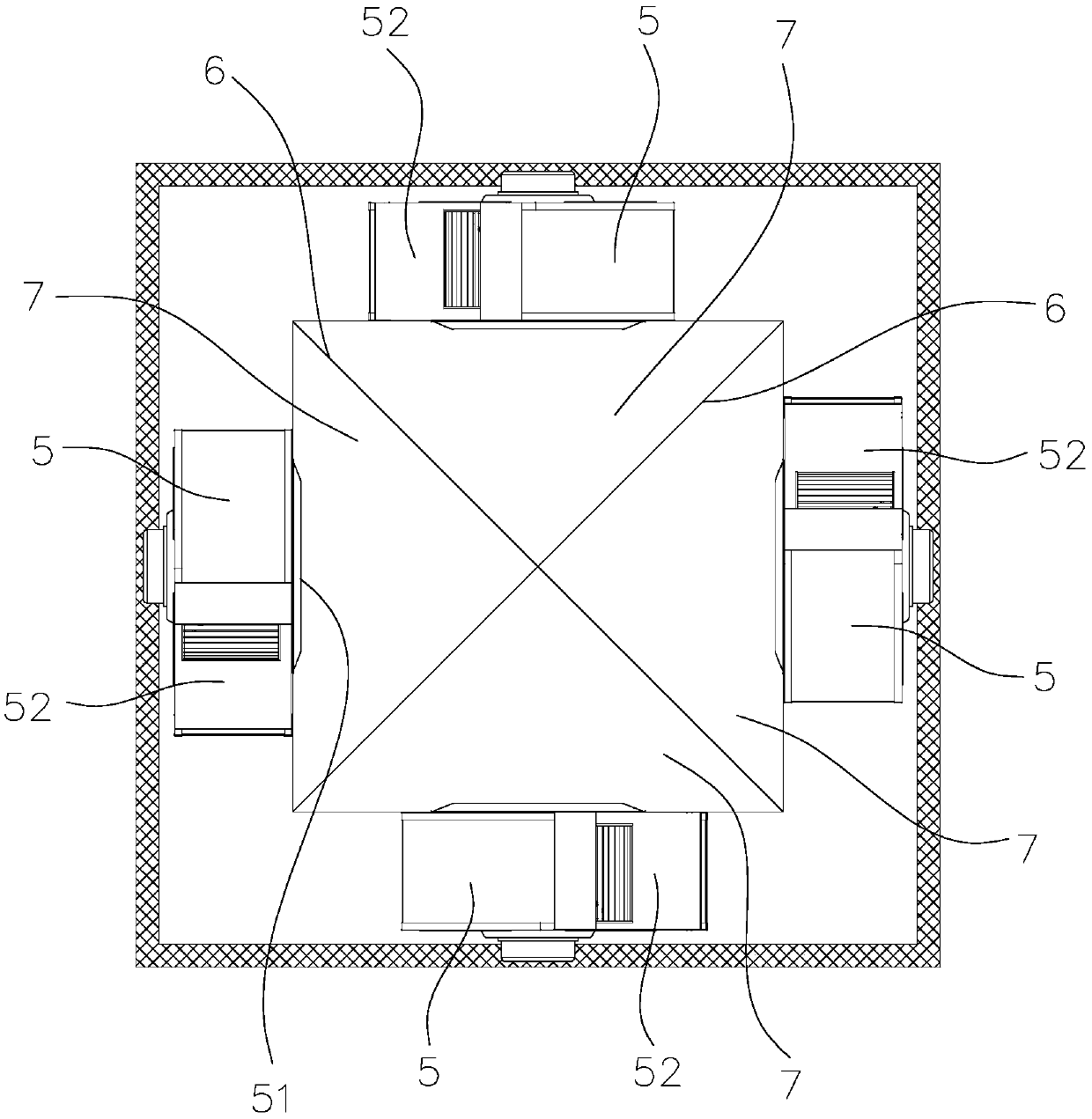

[0042] Such as Figure 4 As shown, in this embodiment, there are also four flue fans 5 in the central flue system and they are correspondingly arranged on the four side walls of the air outlet channel 4. The difference from Embodiment 1 lies in the distribution of the air duct partitions 6 different ways. In this embodiment, there are three air duct partitions 6 and are distributed in an H shape. The air duct partitions 6 divide the interior of the air outlet channel 4 into four mutually isolated air inlet areas 7, and the air outlet of each flue fan 5 Corresponding to the air inlet area 7 one by one. The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be further described here.

Embodiment 3

[0044] Such as Figure 5 As shown, in this embodiment, there are three flue fans 5 of the central flue system and are arranged on the three side walls of the air outlet channel 4, and there are two air duct partitions 6 and are distributed in a T shape. The plate 6 divides the inside of the air outlet channel 4 into three mutually isolated air inlet areas 7 , and the air outlet of each flue fan 5 corresponds to the air inlet areas 7 one by one. The rest of the structure of this embodiment is the same as that of Embodiment 1, and will not be further described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com