Smoke discharging system for plasma cutting machine

A technology of plasma cutting machine and fume extraction system, which is applied in the direction of plasma welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of polluting the on-site environment and physical harm of on-site operators, and achieves the effect of ensuring high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

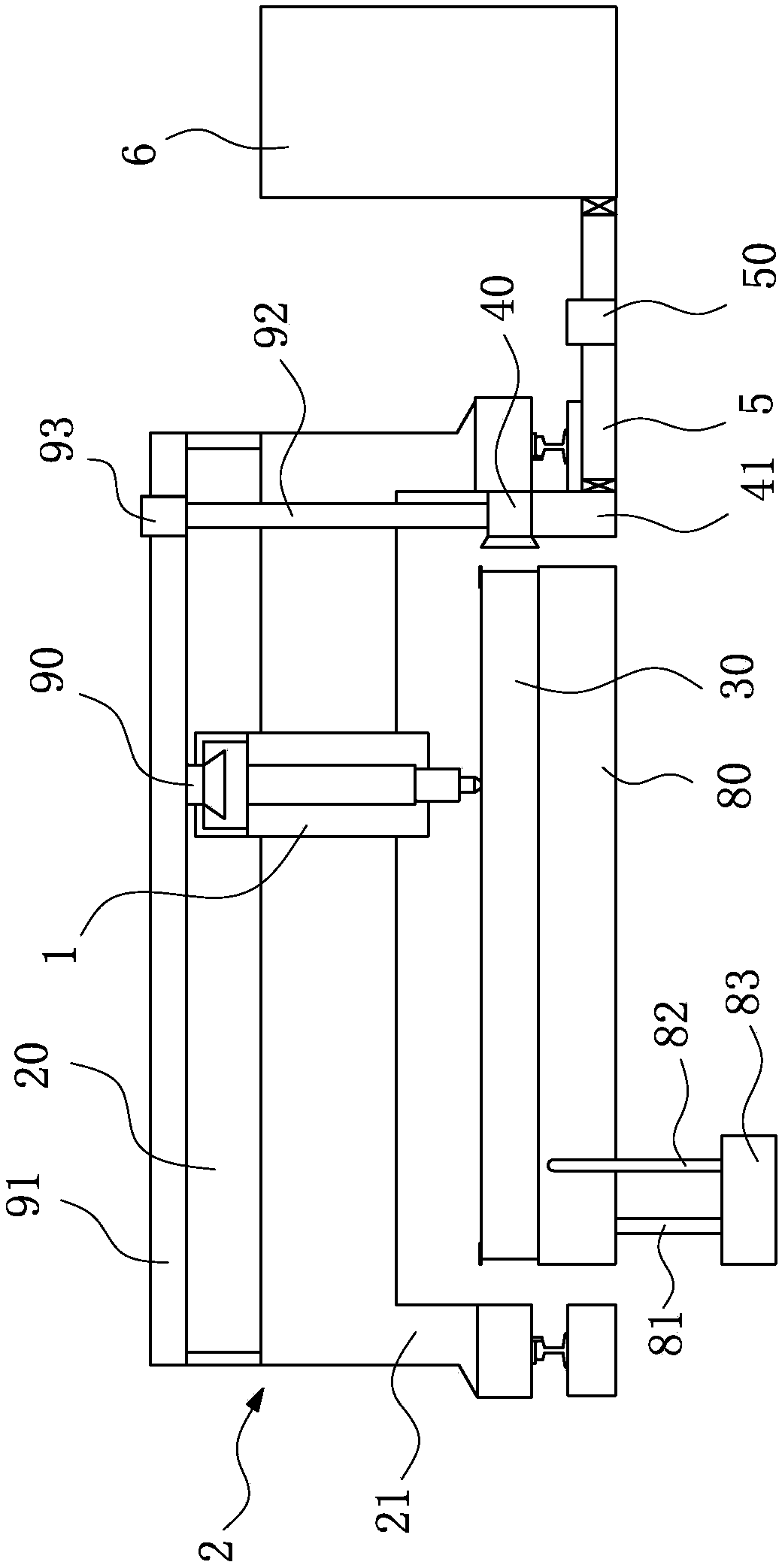

[0034] Such as figure 1 As shown, a smoke exhaust system for a plasma cutting machine. The plasma cutting machine includes a cutting head 1, a sliding frame 2, and a cutting table 3. The cutting table 3 is used to place processed products. Rails are provided on both sides of the cutting table 3. The carriage 2 includes a crossbeam 20 and support arms 21 located at both ends of the crossbeam 20. The two support arms 21 are respectively slidably mounted on the rails on both sides. The cutting head 1 is installed on the crossbeam 20 and can slide along the crossbeam 20 under the drive of the motor. That is, the displacement adjustment in the X direction and the Y direction in the horizontal plane is used to realize the adjustment of the cutting position of the cutting machine.

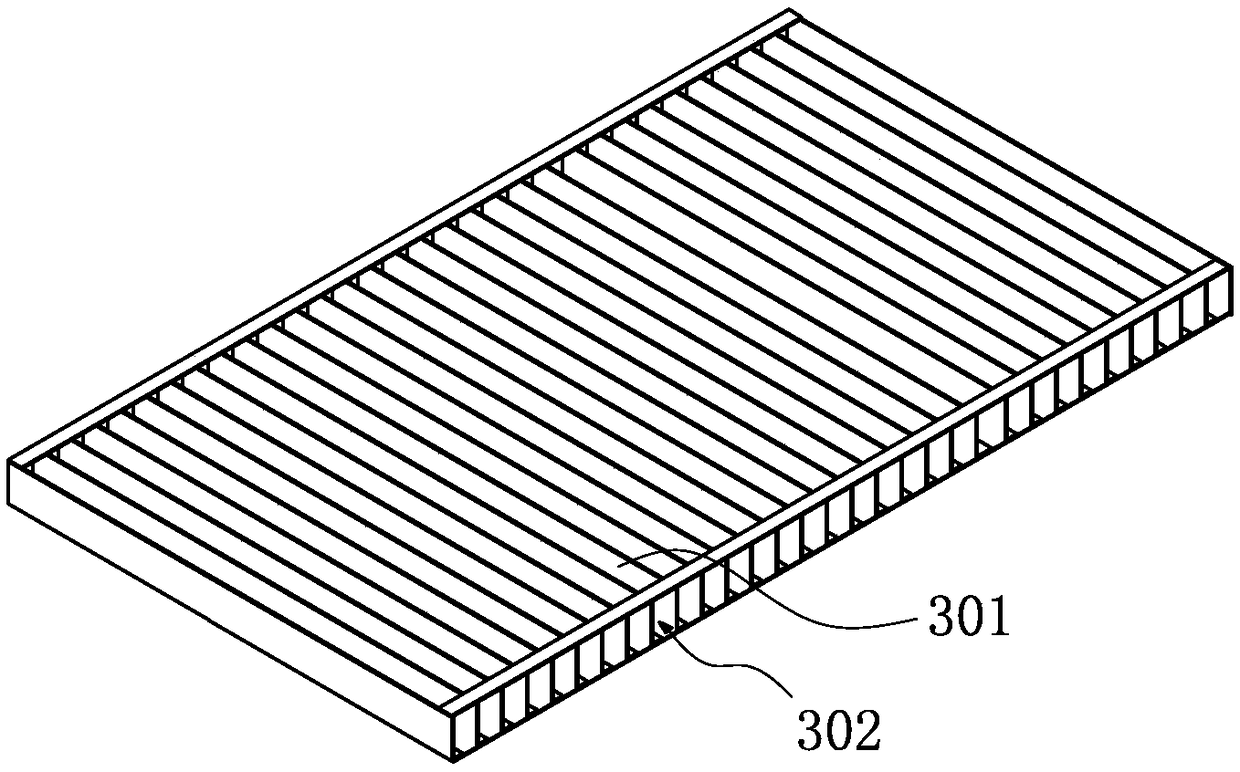

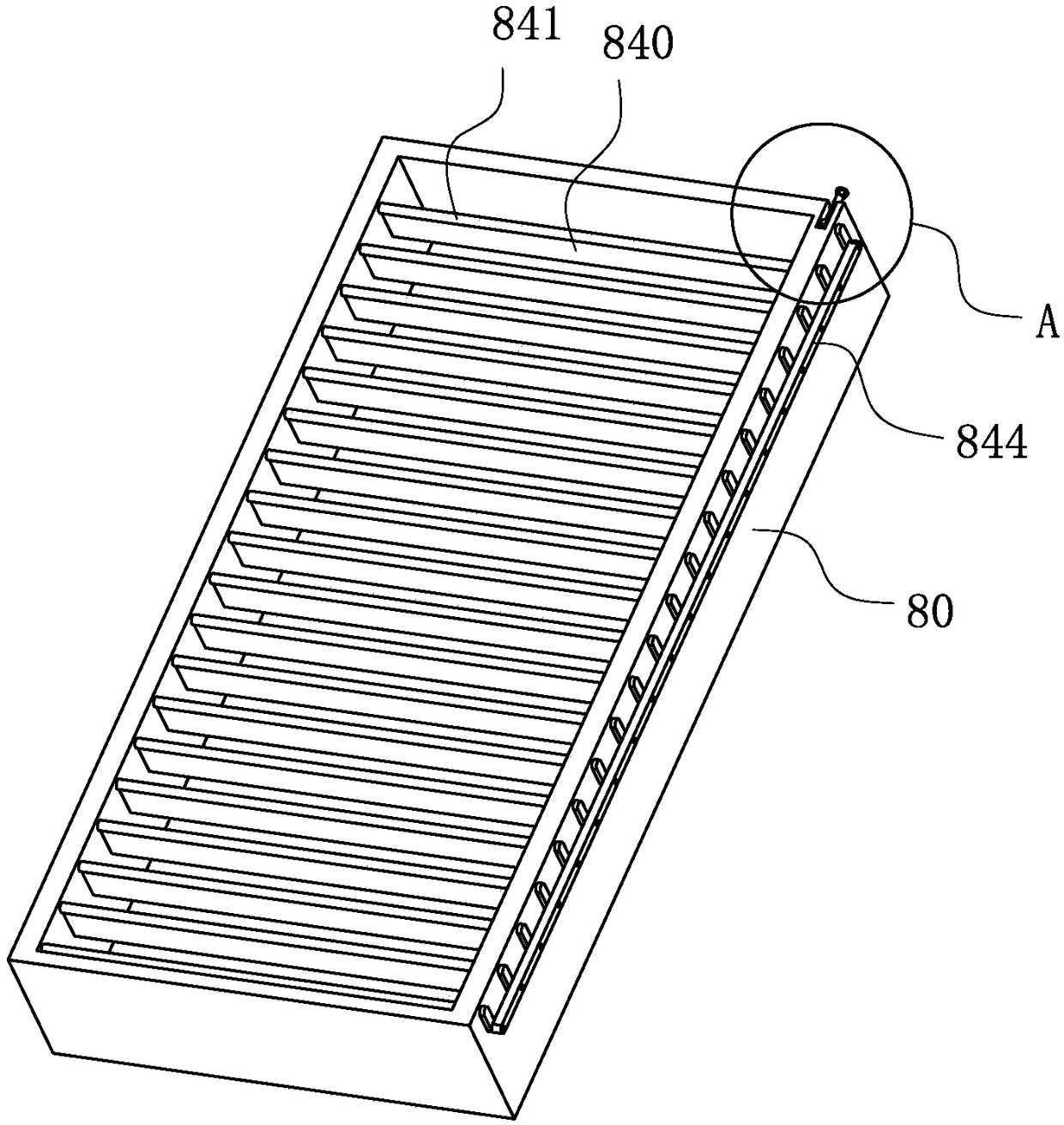

[0035] Such as figure 2 As shown, the top of the cutting table 3 is a grid 30, and the bottom is a water tank 80. The grid 30 includes a plurality of vertical partitions 301, and the plurality of vertic...

Embodiment 2

[0041] The difference between this embodiment and Embodiment 1 is that: Figure 6 As shown, one side of the smoke collection channel 302 is the air suction device 4, and the other side is the air blowing device 7, the air blowing device 7 is installed on the support arm 21, and the air outlet of the air blowing device 7 is connected to the first sliding suction end 40 The suction port is directly opposite, and the air blowing device 7 can blow the smoke to the first sliding suction end 40, so as to accelerate the collection of the smoke and dust. In this embodiment, the blowing device 7 is a light blower 50.

Embodiment 3

[0043] The difference between this embodiment and Embodiment 1 is that: Figure 7 As shown, there are two air suction devices 4, and the two air suction devices 4 are symmetrically arranged on both sides of the smoke collection channel 302, so as to strengthen the ability of the smoke exhaust system to collect smoke and dust, and avoid a single air suction device 4. Insufficient suction force causes a weak smoke collection area to be formed on the smoke collection channel 302 . In this embodiment, two suction devices 4 are connected to the same air duct 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com