A semi-static pressure air supply device and drying equipment

An air supply device and static pressure technology, applied in the field of drying, can solve the problems of inability to dry the object to be dried, production waste, low efficiency, etc., and achieve the effect of improving the uneven air output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

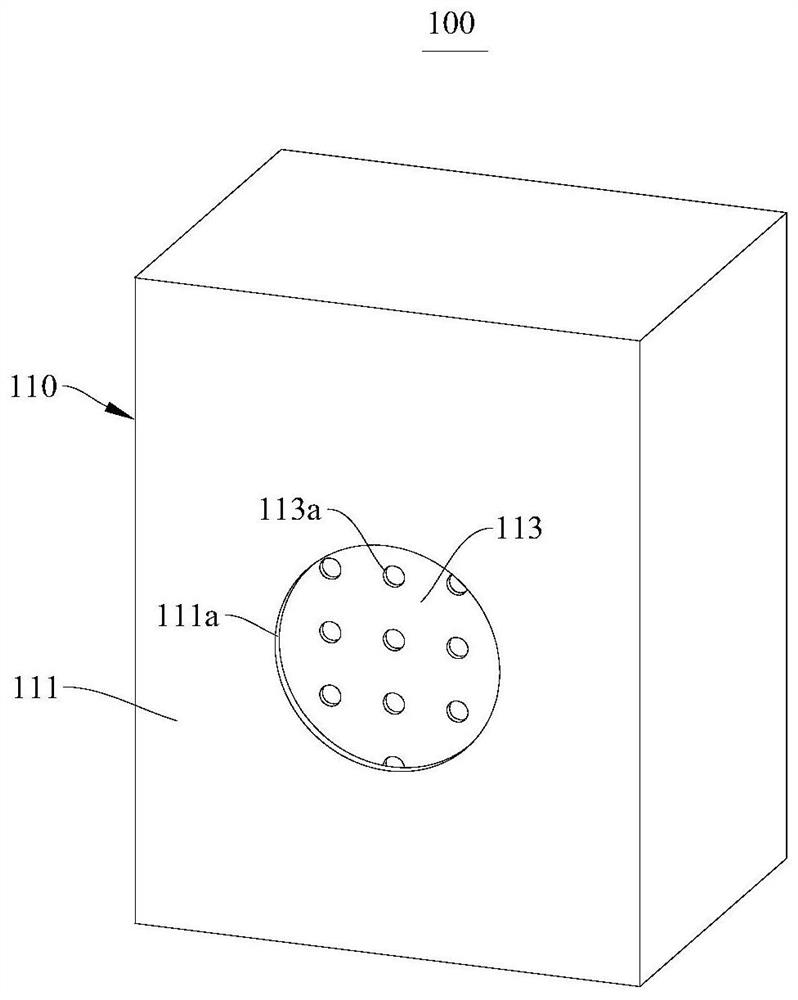

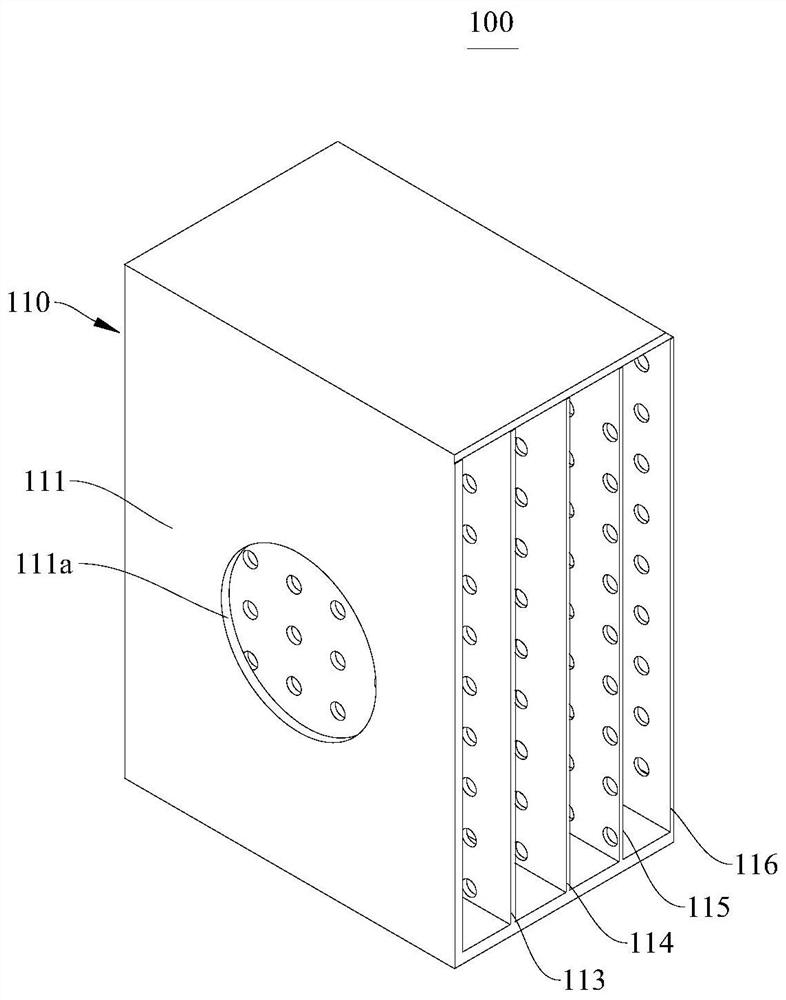

[0032]This embodiment provides a semi-static pressure blowing device 100, please refer tofigure 1 withfigure 2 The semi-static air blowing device 100 is used to be placed between the heat source and the material to be dried. The semi-static air blowing device 100 includes a box body 110 and a fan (not shown in the figure).

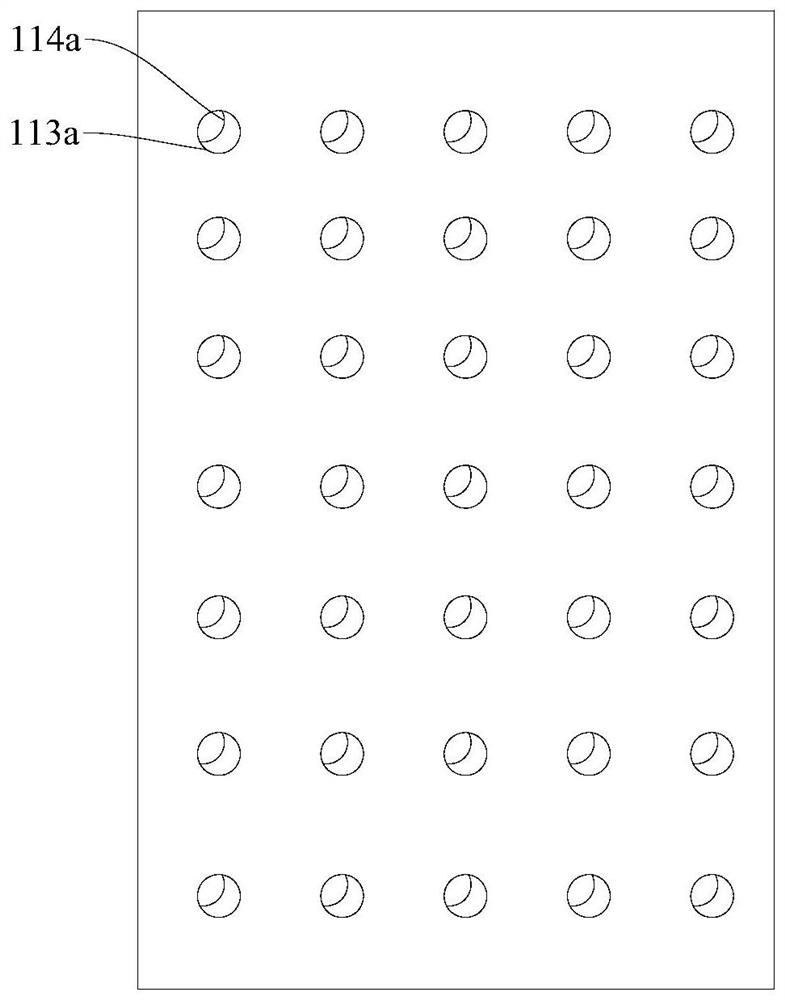

[0033]The box body 110 includes a mounting plate 111 and at least two wind deflectors. The mounting plate 111 and the wind deflector are arranged in the direction of the heat source toward the drying material. The mounting plate 111 is provided with mounting holes 111a. With gaps, the wind deflectors are provided with multiple air outlets. The ratio of the total area of the multiple air outlets to the area of the wind deflector is 1:3-14. In this embodiment, the windshields are all arranged substantially perpendicular to the bottom of the box body 110, and the box body 110 has a rectangular parallelepiped shape. In other embodiments, the box 110 may be cylindri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com