Movable skeleton for blueberry planting greenhouses

A greenhouse and activity technology, applied in the field of blueberry planting equipment, can solve the problems of not easy to reuse, the frame of the greenhouse is fragile, and the structure is not stable enough, and achieves the effect of convenient disassembly and assembly, good fixation, and increased grip area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

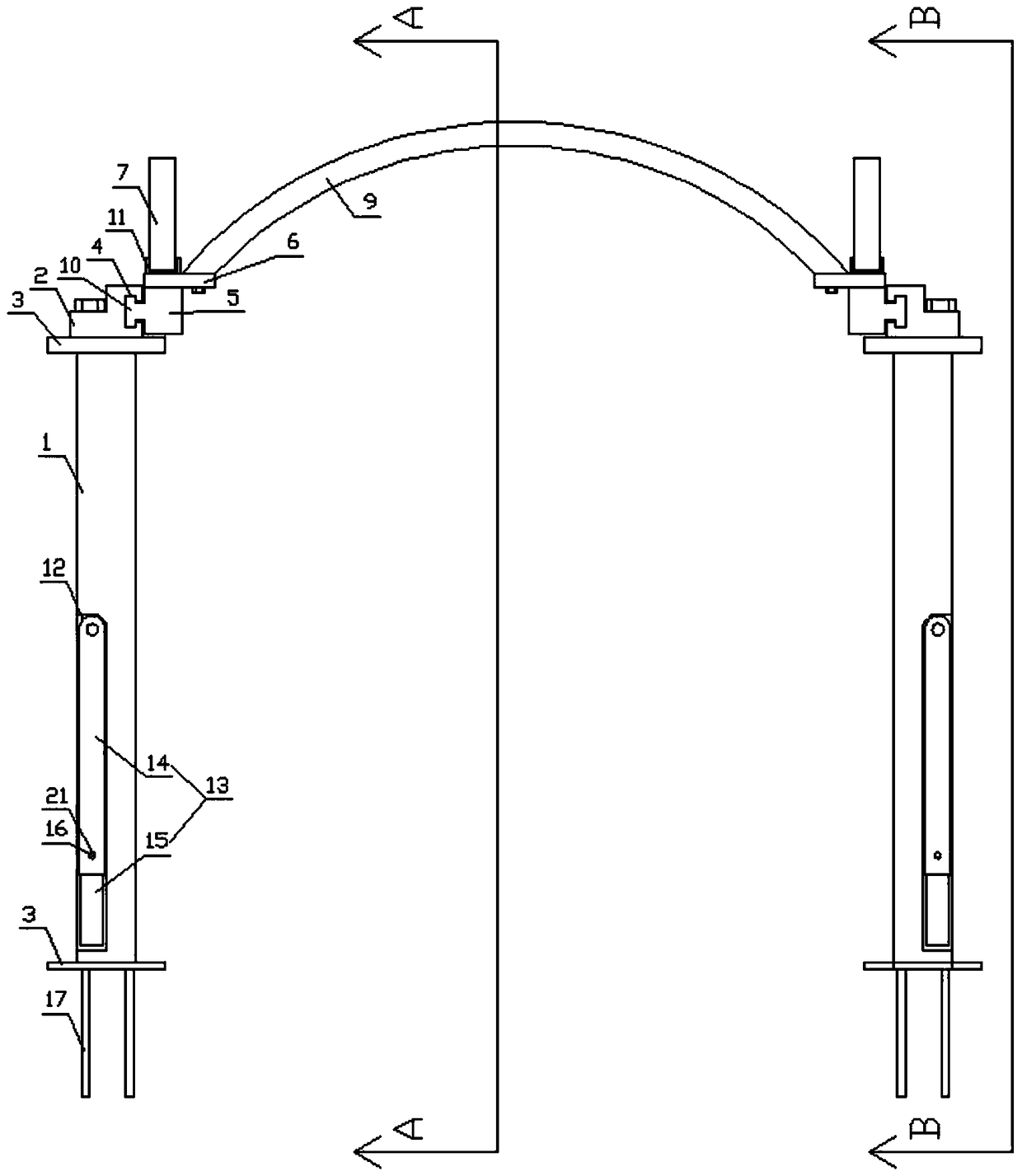

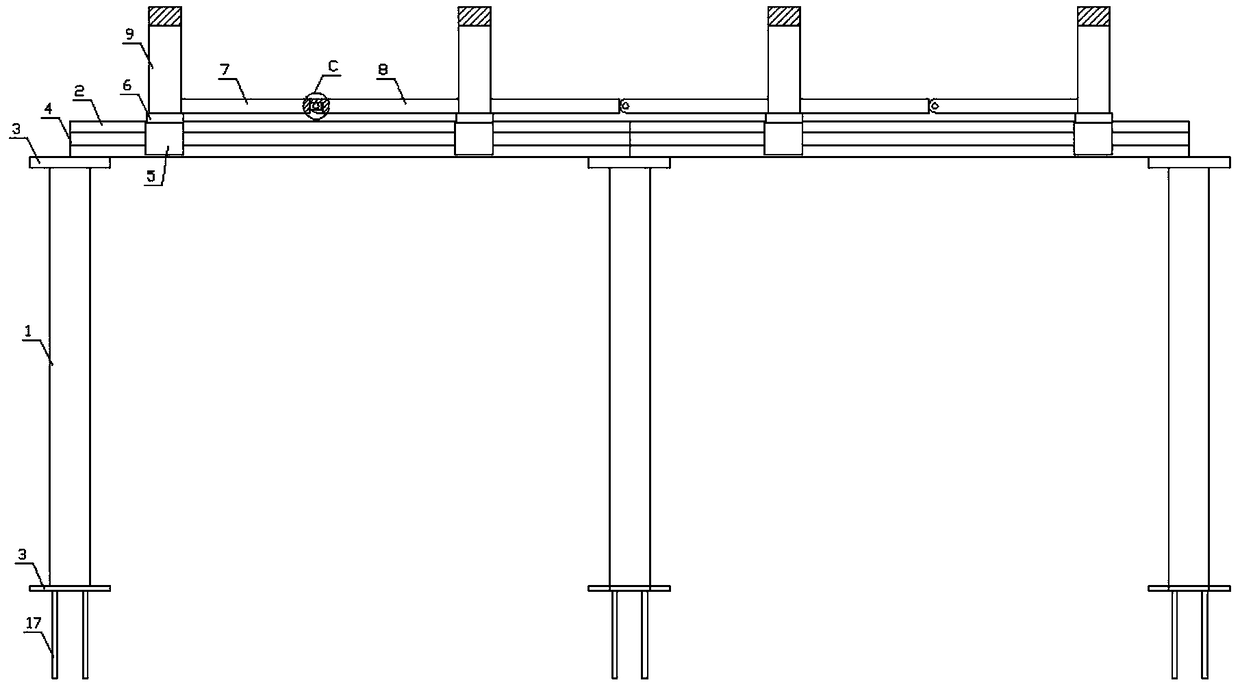

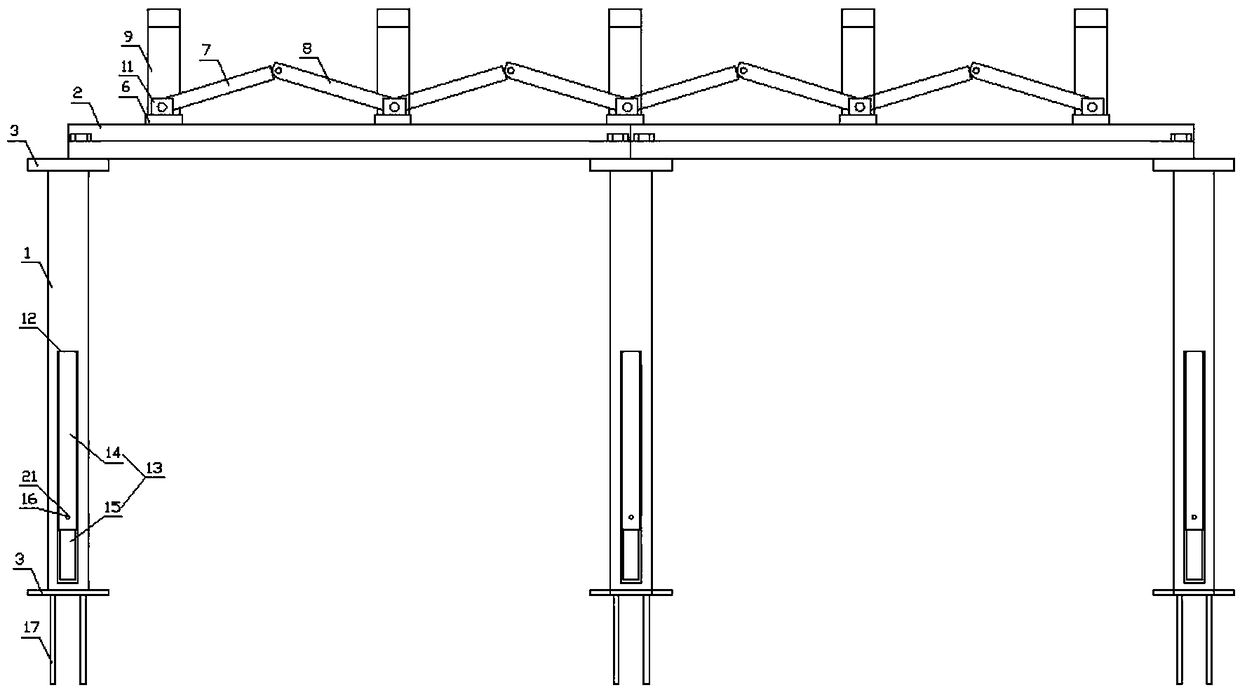

[0018] Figure 1-5 A preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings. A blueberry planting greenhouse movable skeleton, including several vertical support rods 1, L-shaped horizontal support rods 2, and slidable support devices, the upper and lower ends of the vertical support rods 1 are A rectangular platform 3 is provided, and the L-shaped horizontal support rod 2 is fixed between the rectangular platforms 3 at the upper ends of the two vertical support rods 1 by bolts. The inner side wall of the L-shaped horizontal support rod 2 is provided with a convex chute 4. The slidable support device includes a number of symmetrically arranged support sliders 5, support plates 6, first connecting rods 7, second connecting rods 8 and arc-shaped support frames 9, and the sup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com