Mechanical stepping device applicable for large sized bar marshalling bench

A marshalling table, large-scale technology, applied in forging equipment, metal rolling, manufacturing tools, etc., can solve the problems of high investment cost, low production efficiency, large synchronization error, etc., achieve less maintenance workload, improve production efficiency, The effect of small synchronization error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing, the patent of the present invention is described in further detail.

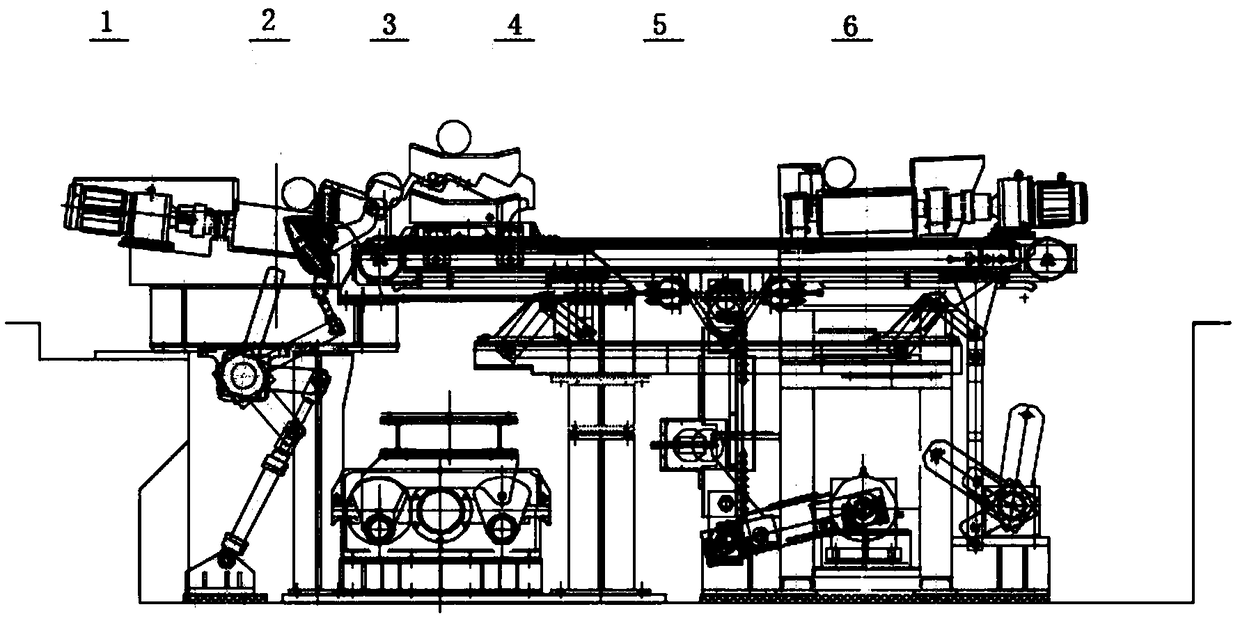

[0031] Such as figure 1 As shown, the general assembly diagram of the large-size bar marshalling stand of the present invention is mainly composed of an input roller table 1, a steel loading device 2, a straightening plate 3, a mechanical stepping device 4, a traverse trolley 5 and an output roller table 6. The role of the input roller table 1 is to transport the finished rolling pieces cut by the finishing mill or flying shear to the steel loading device 2; The straightening plate 3 is installed in the sawtooth groove of the straight plate 3; the straightening plate 3 is installed on the top of the mechanical stepping device 4, and the straightening plate can greatly improve the straightness of the rolled piece; The grouped rolling pieces on the top move across to the output roller table 6, and the grouped rolled pieces are transported to the sizing eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com