Printing notching machine

A cutting machine and technology of cutting, applied in the field of cutting machine, can solve the problems of continuous cutting of cutting objects, affecting quality problems and production conditions, etc., and achieve the effect of convenient cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

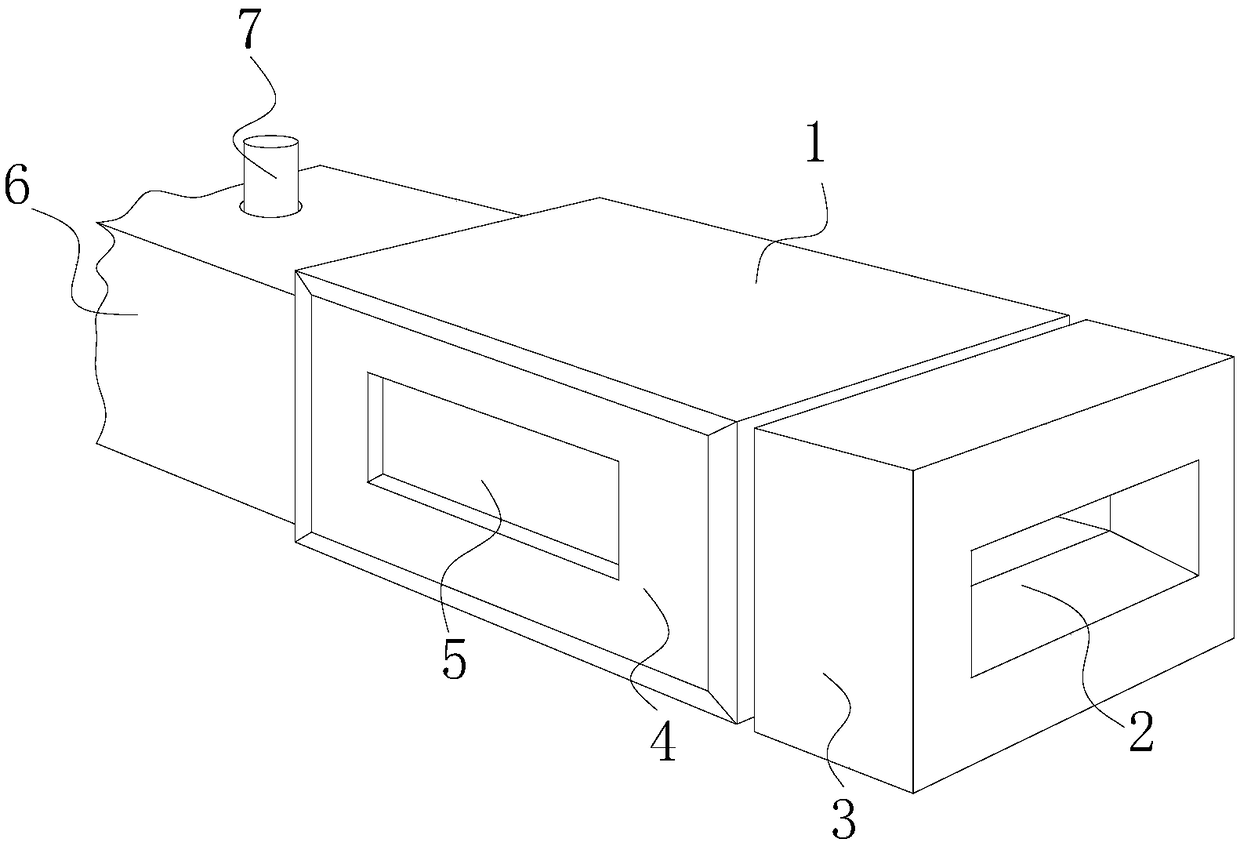

[0023] see Figure 1-Figure 5 , the present invention provides a printing incision machine, including an incision processing device 1, an output port 2, a processing box 3 to be output, a protective compartment 4, an observation end 5, a printing processing connecting grid 6, and a control button 7; the incision processing device 1 is installed On the side of the processing box 3 to be output and connected to each other, the printing processing connecting grid 6 is welded to the end of the processing device 1 away from the processing box 3 to be output and connected to each other, the output port 2 is embedded in the processing box 3 to be output The inside of one end away from the incision treatment device 1, the protective interlayer 4 is attached to both ends of the side of the incision treatment device 1, the observation end 5 is embedded in the inner protective interlayer 4 and is located in the middle, and the bottom of the control button 7 The end is embedded in the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com