Paperboard turnover device

A technology of turning device and cardboard, which is applied in the direction of turning objects, transportation and packaging, pile separation, etc., can solve the problems of needing manual adjustment and unable to change the direction of cardboard, and achieves the effect of reducing manual input, fast turning and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

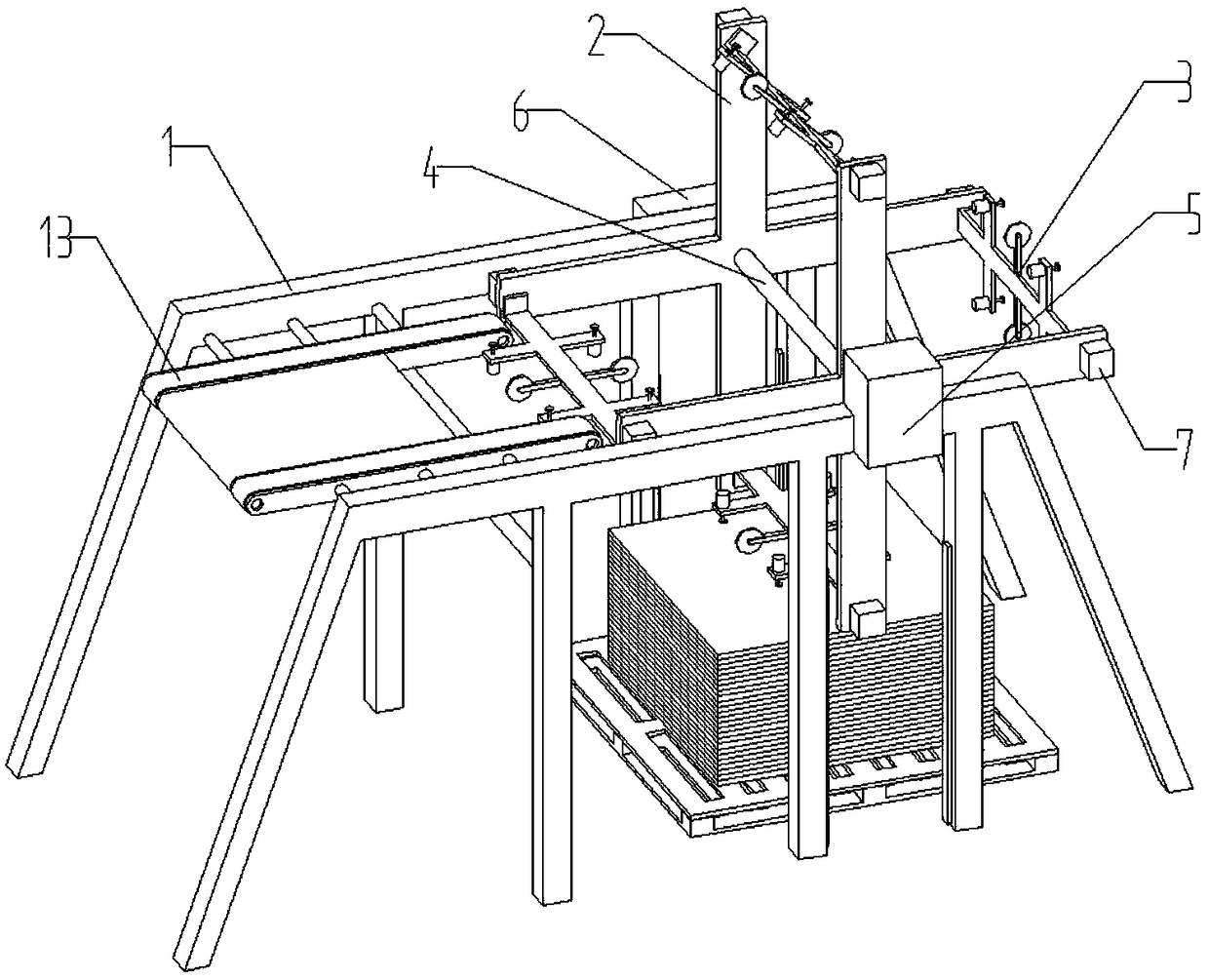

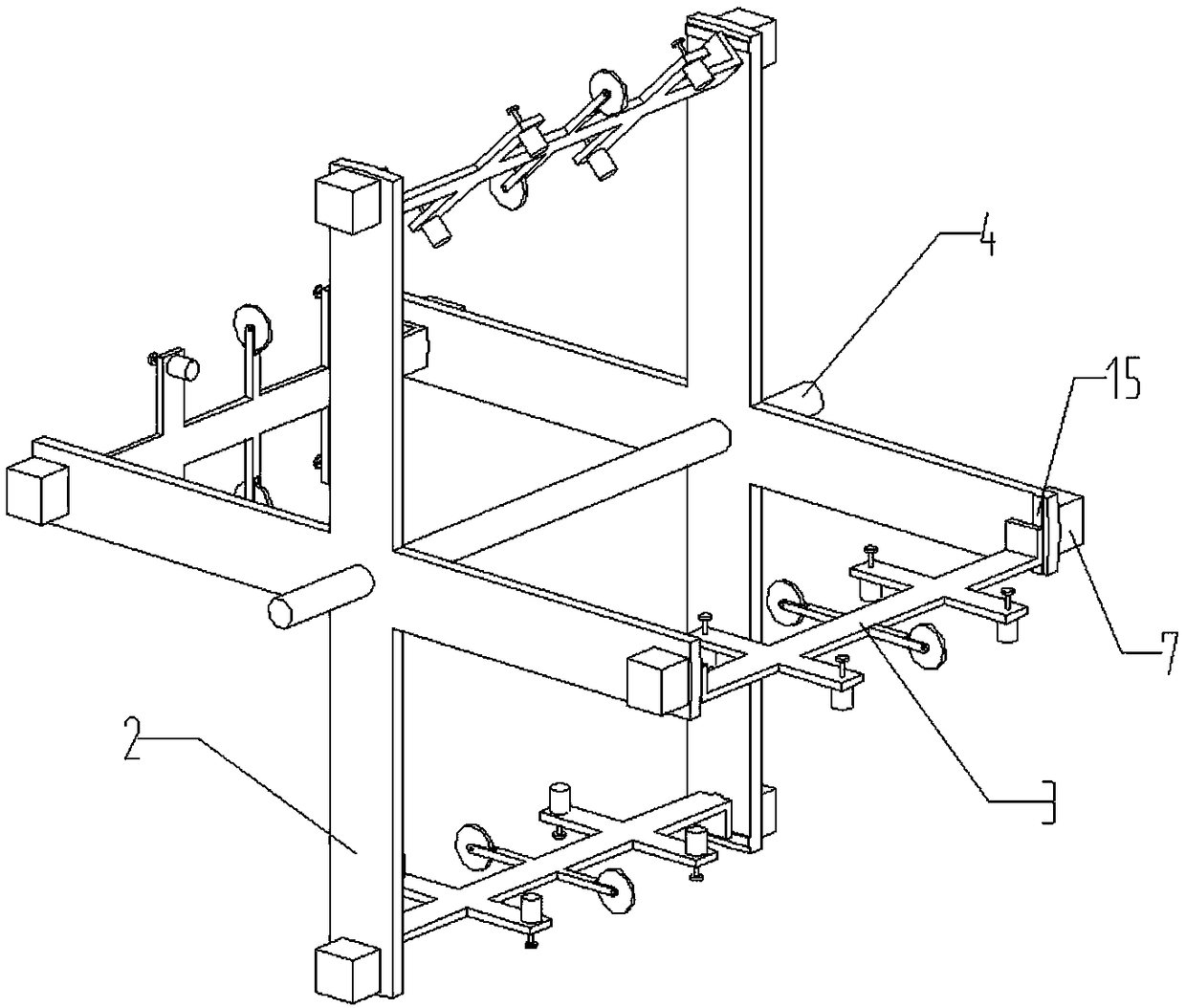

[0021] like figure 1 , figure 2 As shown, a cardboard turning device includes a frame 1, a rotating frame 2, and a turning frame 3. The rotating frame 2 is installed on the frame 1 through a rotating shaft 4. The rotating frame 2 is cross-shaped, and the turning frame 3 has a total of Four, installed on the end of the rotating frame 2 respectively, the rotating shaft 4 is a hollow shaft, one end of the rotating shaft 4 is connected to the motor A5, and the other end is connected to the pneumatic rotary joint 6, and the positive pressure interface is provided on the pneumatic rotary joint 6 and a negative pressure interface, the end of the rotating frame 2 is provided with a motor B7, and the output shaft of the motor B7 is connected with the turning frame 3.

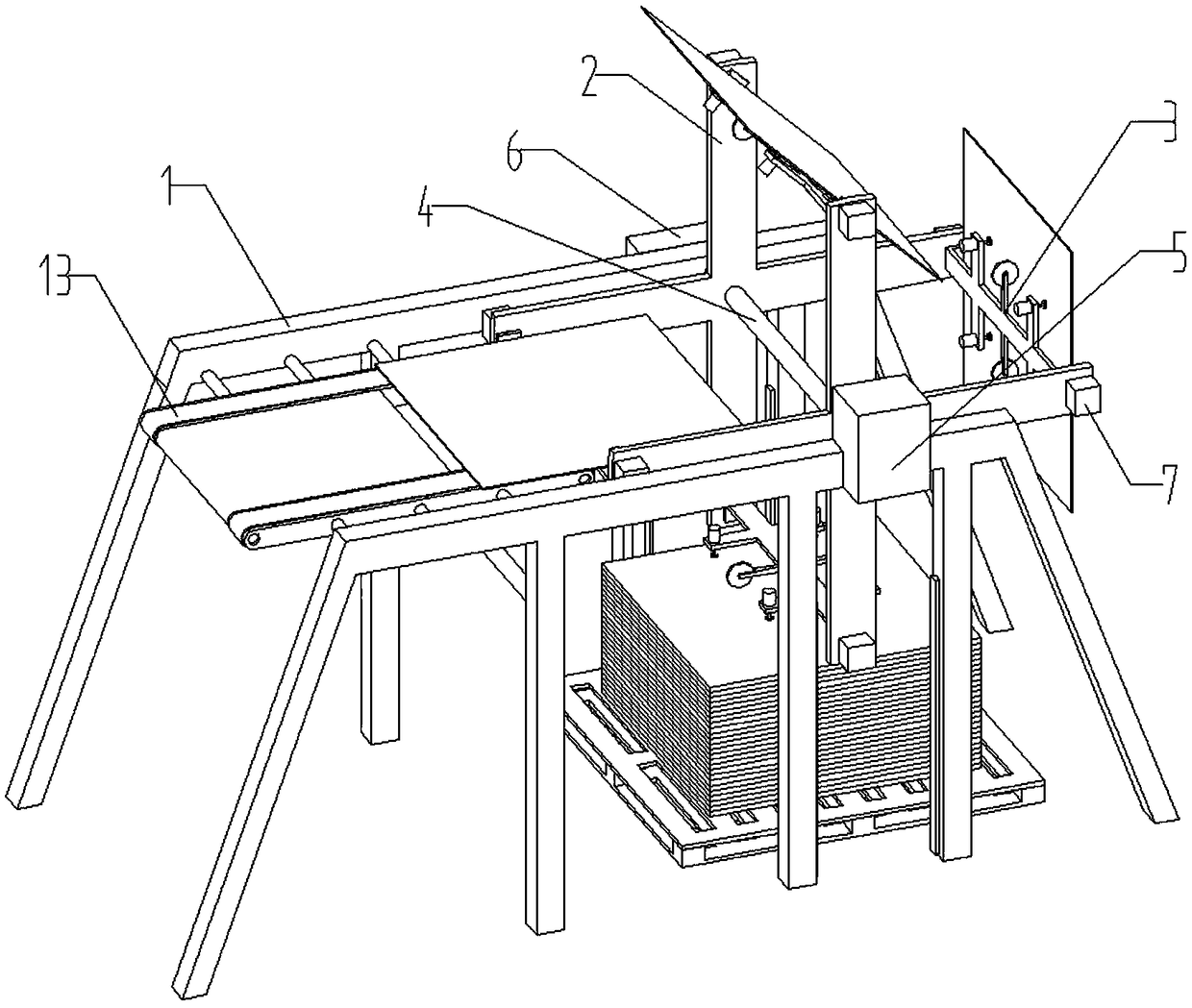

[0022] like image 3 As shown, when working, the motor A5 drives the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap