A ti/carbon aerogel/mno 2 Electrode and its preparation method and application

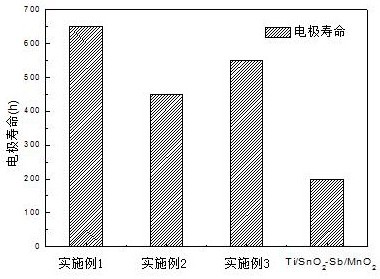

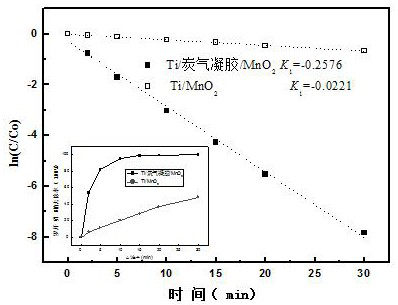

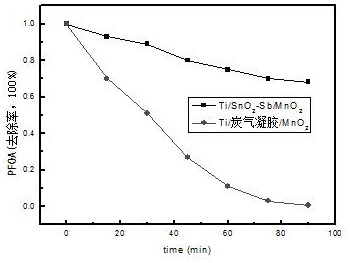

A carbon aerogel and electrode technology, which is applied in the field of Ti/carbon aerogel/MnO2 electrode and its preparation, can solve the problems that it cannot be directly used to prepare large-size anode plates, and the microporous structure of carbon aerogel is easy to collapse. , to achieve the effect of long service life, simple preparation process and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A Ti / carbon aerogel / MnO 2 The preparation method of electrode, comprises the following steps:

[0040] (1) A porous titanium substrate with a pore size of 1 μm, a porosity of 60%, a thickness of 5 mm, and a side length of 3 cm and 5 cm was washed in 10% NaOH solution at 80 °C for 20 min to remove surface oil, and then Pickle in 5% oxalic acid solution at 88°C to remove the oxide film, and then ultrasonicate with deionized water for 10 min;

[0041] (2) Mix resorcinol, formaldehyde, and water at a molar ratio of 1:2:25, stir with a magnetic stirrer at a speed of 350 rpm / min for 15 min, and mix the solution evenly. NaMnO 4 The dosage is 6% of the total mass of the mixture, NaMnO 4 After complete dissolution, continue to stir for 20 min;

[0042] (3) Pour the porous titanium substrate pretreated in step (1) and the mixed solution prepared in step (2) into an organic mold with a volume of 3 cm × 5 cm × 5 mm, and add 10% Na 2 CO 3 an aqueous solution such that the pH of...

Embodiment 2

[0047] A Ti / carbon aerogel / MnO 2 The preparation method of electrode, comprises the following steps:

[0048] (1) A porous titanium substrate with a pore size of 15 μm, a porosity of 80%, a thickness of 5 mm, and a side length of 3 cm and 5 cm was washed in 10% NaOH solution at 80 °C for 20 min to remove surface oil, and then Pickle in 5% oxalic acid solution at 88°C to remove the oxide film, and then ultrasonicate with deionized water for 10 min;

[0049] (2) Mix resorcinol, formaldehyde, and water at a molar ratio of 1.1:2.4:18, stir with a magnetic stirrer at a speed of 350 rpm / min for 15 min, and mix the solution evenly. NaMnO 4 The dosage is 20% of the total mass of the mixture, NaMnO 4 After complete dissolution, continue to stir for 20 min;

[0050] (3) Pour the porous titanium substrate pretreated in step (1) and the mixed solution prepared in step (2) into an organic mold with a volume of 3 cm × 5 cm × 5 mm, and add NaOH with a mass fraction of 10% dropwise an aqu...

Embodiment 3

[0055] A Ti / carbon aerogel / MnO 2 The preparation method of electrode, comprises the following steps:

[0056] (1) A porous titanium substrate with a pore size of 0.5 μm, a porosity of 40%, a thickness of 5 mm, and a side length of 3 cm and 5 cm was washed in 10% NaOH solution at 80 °C for 20 min to remove surface oil, Then pickled in 5% oxalic acid solution at 88°C to remove the oxide film, and then ultrasonicated with deionized water for 10 min;

[0057] (2) Mix resorcinol, formaldehyde, and water at a molar ratio of 1:2.4:30, stir with a magnetic stirrer at a speed of 350 rpm / min for 15 min, and mix the solution evenly. NaMnO 4 The dosage is 40% of the total mass of the mixture, NaMnO 4 After complete dissolution, continue to stir for 20 min;

[0058] (3) Pour the porous titanium substrate pretreated in step (1) and the mixed solution prepared in step (2) into an organic mold with a volume of 3 cm × 5 cm × 5 mm, and add 10% Na 2 CO 3 an aqueous solution so that the pH o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com