Making method for hypersensitive graphene electrode

A graphene electrode and graphene technology, applied in the direction of material electrochemical variables, can solve the problems of inability to achieve accurate detection of mixed purine components, unstable performance of graphene electrodes, and large amount of materials, so as to achieve good surface contact and low cost. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

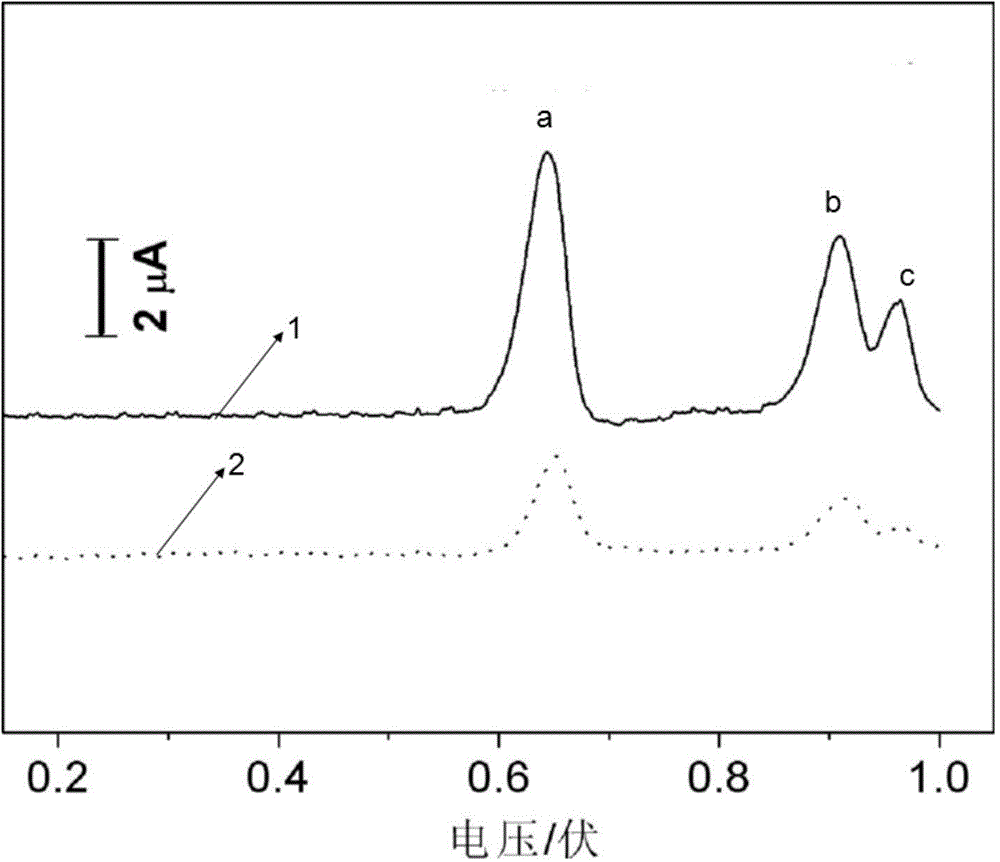

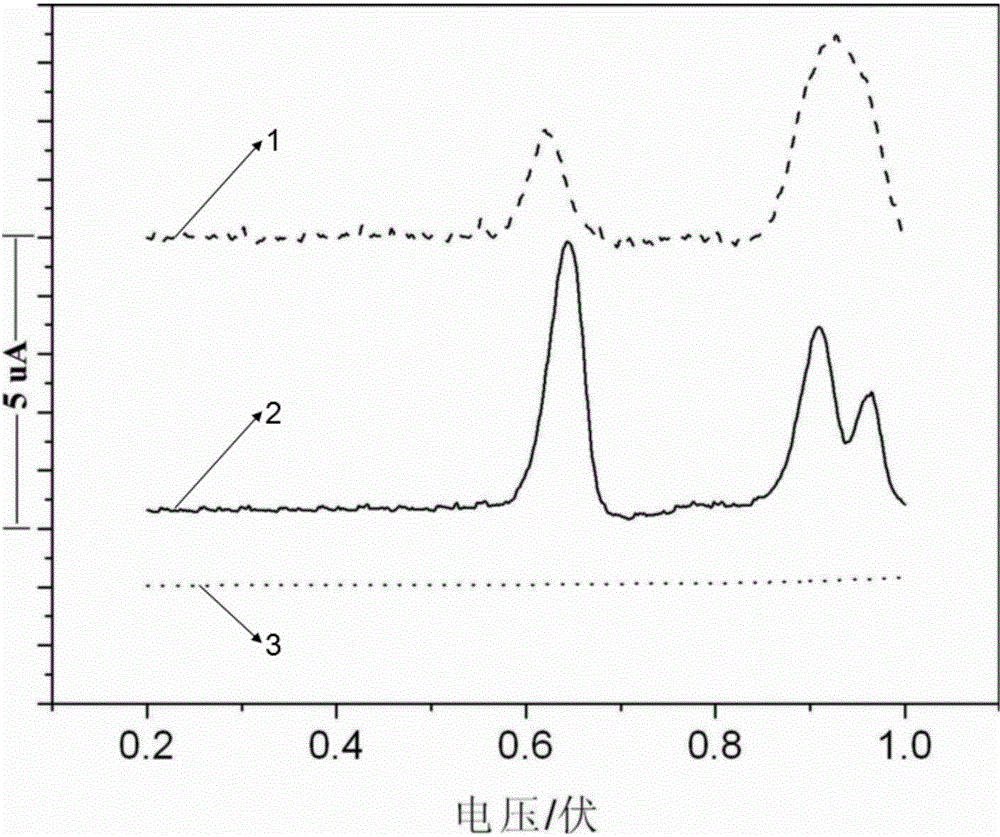

[0019] Embodiment one: a kind of ultra-sensitive graphene electrode of the present embodiment, it is characterized in that it is to be coated on the surface of glassy carbon electrode by the mixed solution of graphene oxide solution and ionic liquid, after being heated and baked by infrared lamp, cooling to room temperature, then perform cyclic voltammetry on the electrode cooled to room temperature in polymerizable monomer / sulfuric acid solution, and then process it in a low-temperature plasma atmosphere after drying; the graphene oxide solution is made of graphite oxide Graphene oxide and solvent are mixed, and the volume ratio of the mass of described graphene oxide to solvent is 1mg:(1mL-3.3mL), the volume ratio of graphene oxide solution and ionic liquid is 1mL:(0.8μL-6μL).

specific Embodiment approach 2

[0020] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the graphene oxide is a single-layer graphene oxide or an oligolayer graphene oxide, and the oligolayer in the oligolayer graphene oxide is 4- 12 layers; wherein the solvent is water or dimethylamide, and the solubility of the solution is above 1.0 mg / mL. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0021] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the ionic liquid is 1-ethyl-3-methylimidazolium hexafluorophosphate, 1-butyl-3-methyl Imidazolium hexafluorophosphate, 1-hexyl-3-methylimidazolium hexafluorophosphate, 1-octyl-3-methylimidazolium hexafluorophosphate, O-benzotriazole-N,N, N',N'-tetramethyluronium hexafluorophosphate, O-(1H-6-chlorobenzotriazol-1-yl)-1,1,3,3-tetramethyluronium hexafluoro One of phosphate and 1-(chloro-1-pyrrolidinylmethylene) pyrrolidinium hexafluorophosphate or a mixture of several of them mixed in any ratio. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com