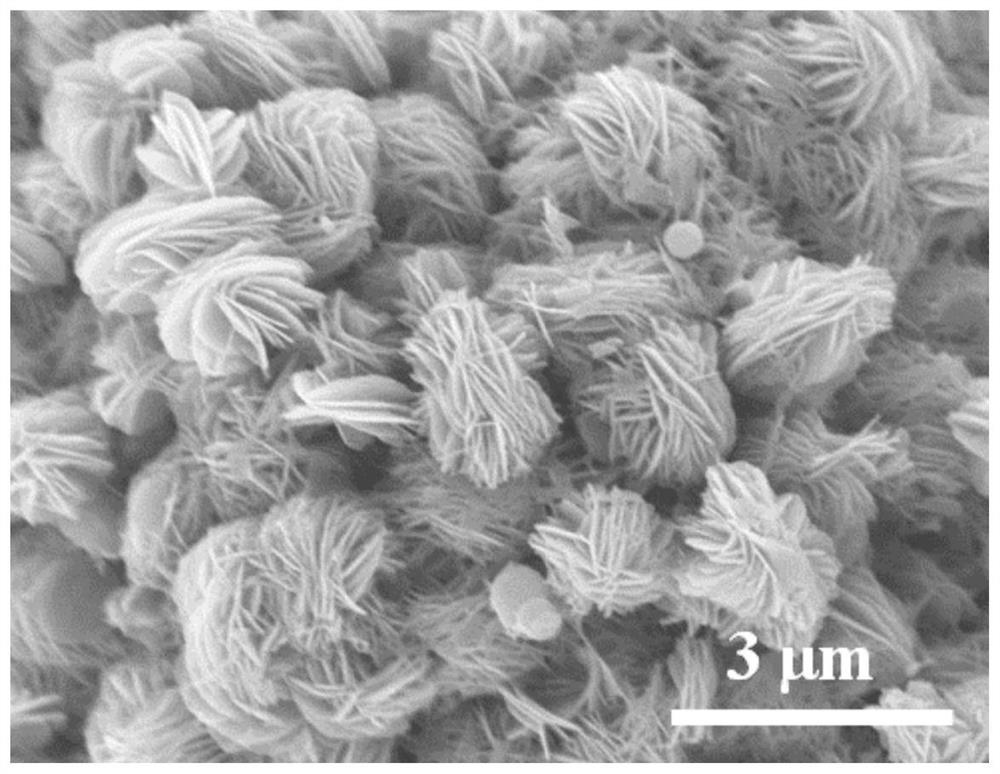

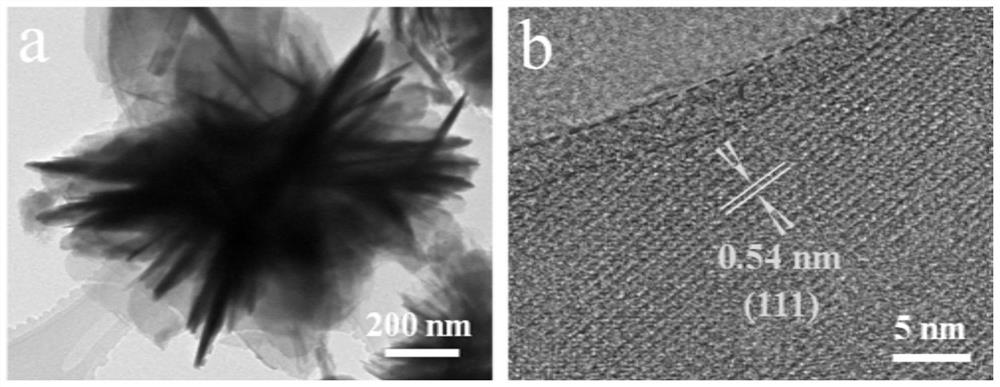

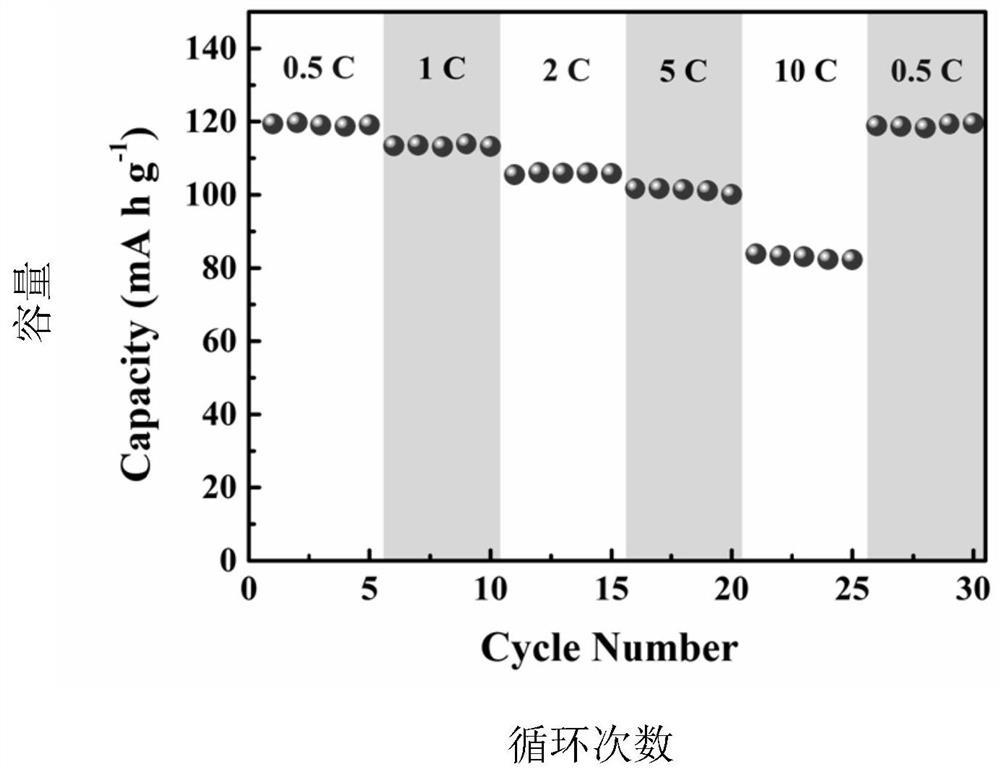

A nanosheet flower-shaped sodium vanadium oxyphosphate electrode material and its preparation method and application

A technology of sodium vanadium oxyphosphate and electrode materials, which is applied in nanotechnology, battery electrodes, nanotechnology, etc., can solve problems such as poor electronic conductivity, and achieve stable electrode performance, good electrochemical performance, and uniform size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Dissolve 4mmol of ammonium metavanadate and 4mmol of citric acid in a mixed solution (70ml) of water and polyethylene glycol-400 with a volume ratio of 1:1, and stir in a water bath at 70°C until a blue color is formed Mix the solution evenly, then dissolve 4mmol ammonium dihydrogen phosphate and 6mmol sodium fluoride in the mixed solution, and obtain a uniform solution after continuous stirring;

[0032] (2) Dissolve 0.3g polyethylene glycol-20000 in the homogeneous solution prepared in step (1), fully stir and dissolve to obtain the precursor solution;

[0033] (3) Add the precursor solution prepared in step (2) into a polytetrafluoroethylene autoclave, seal it and place it in an electric oven for hydrothermal reaction at 200°C for 8 hours to obtain the precursor powder;

[0034] (4) After the precursor powder obtained in step (3) is centrifugally washed, separated and dried, it is placed in a high-temperature tube furnace for high-temperature preheating treatment...

Embodiment 2

[0036] (1) Dissolve 4mmol of ammonium metavanadate and 4mmol of citric acid in a mixed solution (70ml) of water and polyethylene glycol-400 with a volume ratio of 1:2, and stir in a water bath at 70°C until blue is formed Mix the solution evenly, then dissolve 4mmol ammonium dihydrogen phosphate and 6mmol sodium fluoride in the mixed solution, and obtain a uniform solution after continuous stirring;

[0037] (2) Dissolve 0.4g polyethylene glycol-20000 in the homogeneous solution prepared in step (1), fully stir and dissolve to obtain the precursor solution;

[0038] (3) Add the precursor solution prepared in step (2) into a polytetrafluoroethylene autoclave, seal it and place it in an electric oven for hydrothermal reaction at 200°C for 10 hours to obtain the precursor powder;

[0039] (4) After the precursor powder prepared in step (3) is centrifugally washed, separated and dried, it is placed in a high-temperature tube furnace for high-temperature preheating under an argon atm...

Embodiment 3

[0041] (1) Dissolve 4mmol ammonium metavanadate and 4mmol citric acid in a mixed solution (70ml) of water and polyethylene glycol-400 with a volume ratio of 1:4, and stir in a water bath at 70°C until blue is formed Mix the solution evenly, then dissolve 4mmol ammonium dihydrogen phosphate and 6mmol sodium fluoride in the mixed solution, and obtain a uniform solution after continuous stirring;

[0042] (2) Dissolve 0.6g polyethylene glycol-20000 in the homogeneous solution prepared in step (1), fully stir and dissolve to obtain the precursor solution;

[0043] (3) Add the precursor solution prepared in step (2) into a polytetrafluoroethylene autoclave, seal it and place it in an electric oven for hydrothermal reaction at 200°C for 12 hours to obtain a precursor powder;

[0044] (4) After the precursor powder prepared in step (3) is centrifugally washed, separated and dried, it is placed in a high-temperature tube furnace for high-temperature preheating treatment under an argon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com