Water channel device, composite filter cartridge device and composite filter cartridge filtering system

A composite filter element and water channel technology, applied in the field of water purification, can solve the problems of difficult to replace the filter element, difficult to replace the filter element, and the filter element is matched and fixed, and achieves the effects of sufficient filtration, high utilization rate and long filtration life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

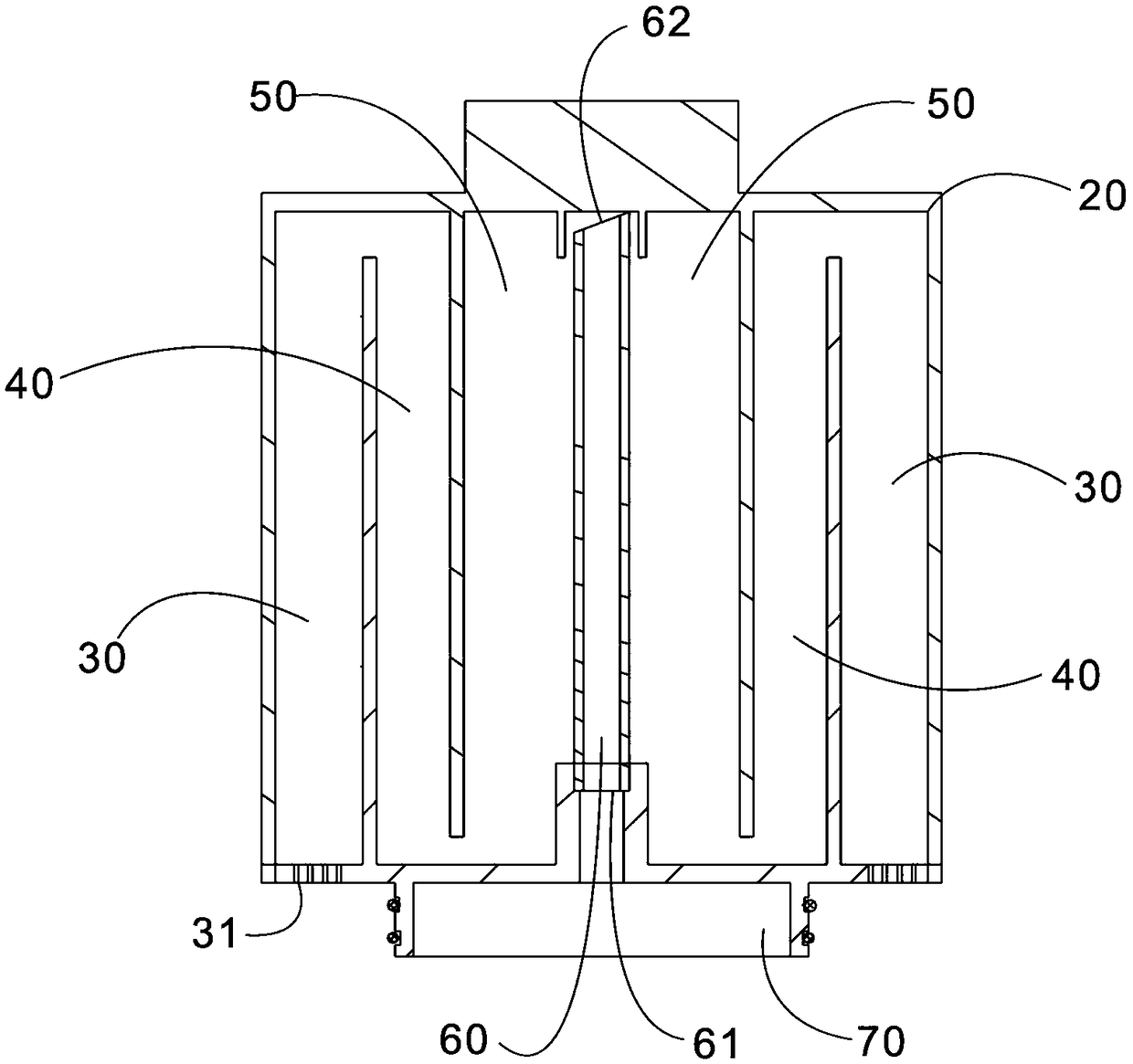

[0041] See figure 2 As shown, a water channel device for filling a composite filter element of this embodiment is provided between the top and bottom ends of a cylinder 20, and in accordance with the direction of water flow, various water channels that circulate in sequence are arranged from the outside to the inside. From the outside to the inside, the waterway includes a circular cylindrical water inlet 30, a circular cylindrical first intermediate water channel 40, a circular cylindrical second intermediate water channel 50, and an optional cylindrical fifth water channel 60.

[0042] The annular cylindrical water inlet 30 has a water inlet 31 at the bottom end.

[0043] The top end of the first intermediate water channel 40 in the shape of a ring column is communicated with the top end of the water inlet channel.

[0044] The second intermediate water channel 50 in the shape of a circular column has a bottom end communicated with the bottom end of the first intermediate water ch...

Embodiment 2

[0050] Referring to Example 1, see image 3 As shown, the difference from Embodiment 1 is that the top end of the water outlet 60 is not provided with an oblique opening, but a gap 62 is directly provided to communicate with the top of the second intermediate water channel 50.

Embodiment 3

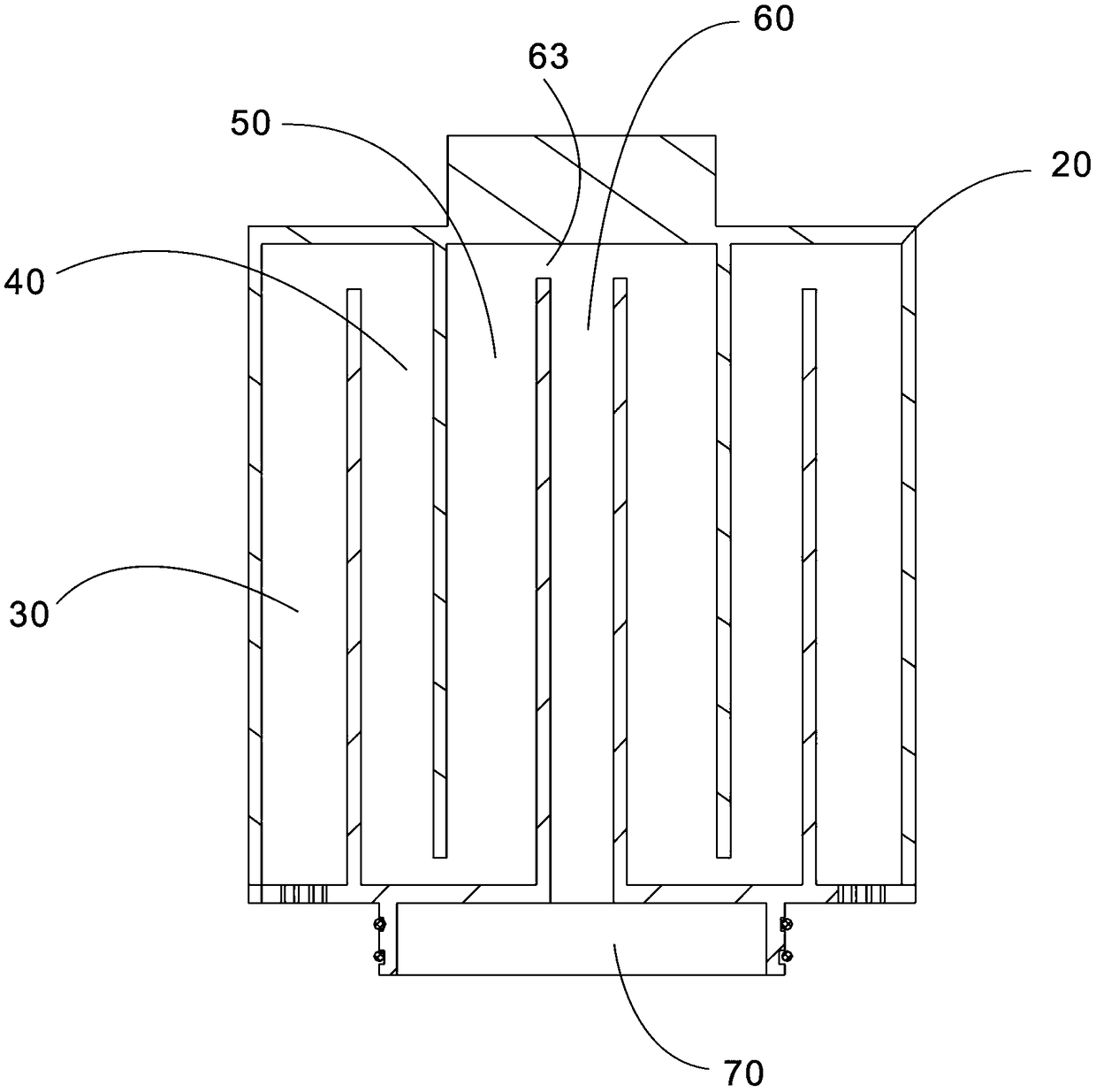

[0052] Referring to Example 1, see Figure 4 As shown, the difference from Embodiment 1 is that the second middle water channel 50 is provided with an installation groove 51 for fixing the filter element. And lower the position of the oblique opening 62 of the water outlet.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap