Crude wood vinegar impurity-removing and quality-improving technology and application thereof

A wood vinegar liquor and a crude technology are applied in the technical field of decontamination and quality improvement of the crude wood vinegar liquor, and can solve the problem that it is difficult to remove the harmful components of trifenthopyr, bacteriostatic, bactericidal, and weak antiviral performance, equipment and technology. The problem of high cost is to achieve the effect of adjustable and controllable production scale, no residual pollution and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

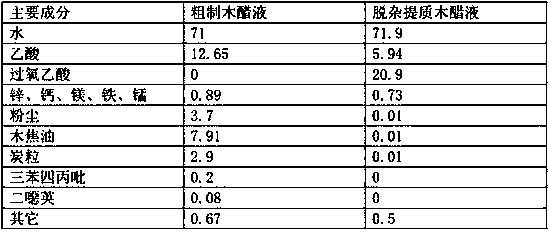

Embodiment 1

[0031] A process for removing impurities and improving quality of crude wood vinegar is characterized in that it comprises the following steps:

[0032] (1) Decolorization: Add a strong base anion exchange resin to the crude wood vinegar, the amount of the strong base anion exchange resin added is 10% of the mass of the crude wood vinegar, add a strong base to the crude wood vinegar The anion exchange resin is fully mixed and exchanged for 2 hours. After the exchange is completed, filter the exchange resin with a 40-mesh filter;

[0033] (2) Separation of impurities and removal of peculiar smell: In the crude wood vinegar, add hydrogen peroxide to the crude wood vinegar according to the mass ratio of crude wood vinegar and hydrogen peroxide at a ratio of 5:0.5, and after standing for 2 days, use 40 mesh The filter screen filters out impurities to obtain the first separated wood vinegar; add hydrogen peroxide to the first separated wood vinegar according to the ratio of crude w...

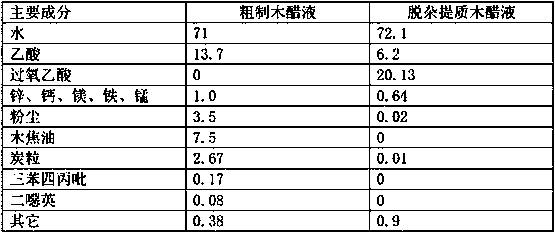

Embodiment 2

[0041] A process for removing impurities and improving quality of crude wood vinegar is characterized in that it comprises the following steps:

[0042] (1) Decolorization: Add a strong base anion exchange resin to the crude wood vinegar, the amount of the strong base anion exchange resin added is 10% of the mass of the crude wood vinegar, add a strong base to the crude wood vinegar The anion exchange resin is fully mixed and exchanged for 1 hour, and after the exchange is completed, filter the exchange resin with a 40-mesh filter;

[0043] (2) Separation of impurities and removal of peculiar smell: In the crude wood vinegar, add high-quality hydrogen peroxide to the crude wood vinegar according to the mass ratio of crude wood vinegar and hydrogen peroxide at a ratio of 5:0.5. After standing for 2 days, use 40 The purpose filter is to filter out impurities to obtain the first separated wood vinegar; add hydrogen peroxide to the first separated wood vinegar according to the mas...

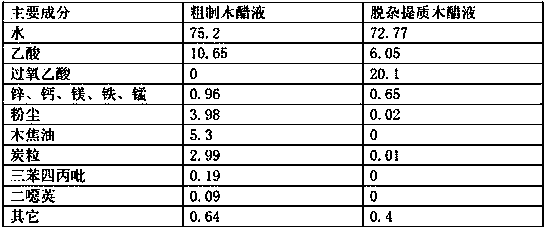

Embodiment 3

[0051] A process for removing impurities and improving quality of crude wood vinegar is characterized in that it comprises the following steps:

[0052] (1) Decolorization: Add a strong base anion exchange resin to the crude wood vinegar, the amount of the strong base anion exchange resin added is 12% of the mass of the crude wood vinegar, add a strong base to the crude wood vinegar The anion exchange resin is fully mixed and exchanged for 2 hours. After the exchange is completed, filter the exchange resin with a 40-mesh filter;

[0053] (2) Separation of impurities and removal of peculiar smell: In the crude wood vinegar, add hydrogen peroxide to the crude wood vinegar according to the mass ratio of crude wood vinegar and hydrogen peroxide at a ratio of 5:0.8, and after standing for 2 days, use 40 mesh The filter screen removes impurities to obtain the first separation of wood vinegar; add hydrogen peroxide to the first separation of wood vinegar according to the ratio of cru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com