Strip steel continuous hot-dip galvanizing system

A hot-dip galvanizing and hot-dip galvanizing technology, which is applied in the hot-dip galvanizing process, coating, metal material coating process, etc., can solve problems such as missing plating in the furnace nose area, improve product surface quality, and avoid quality problems , The effect of solving the problem of missing plating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

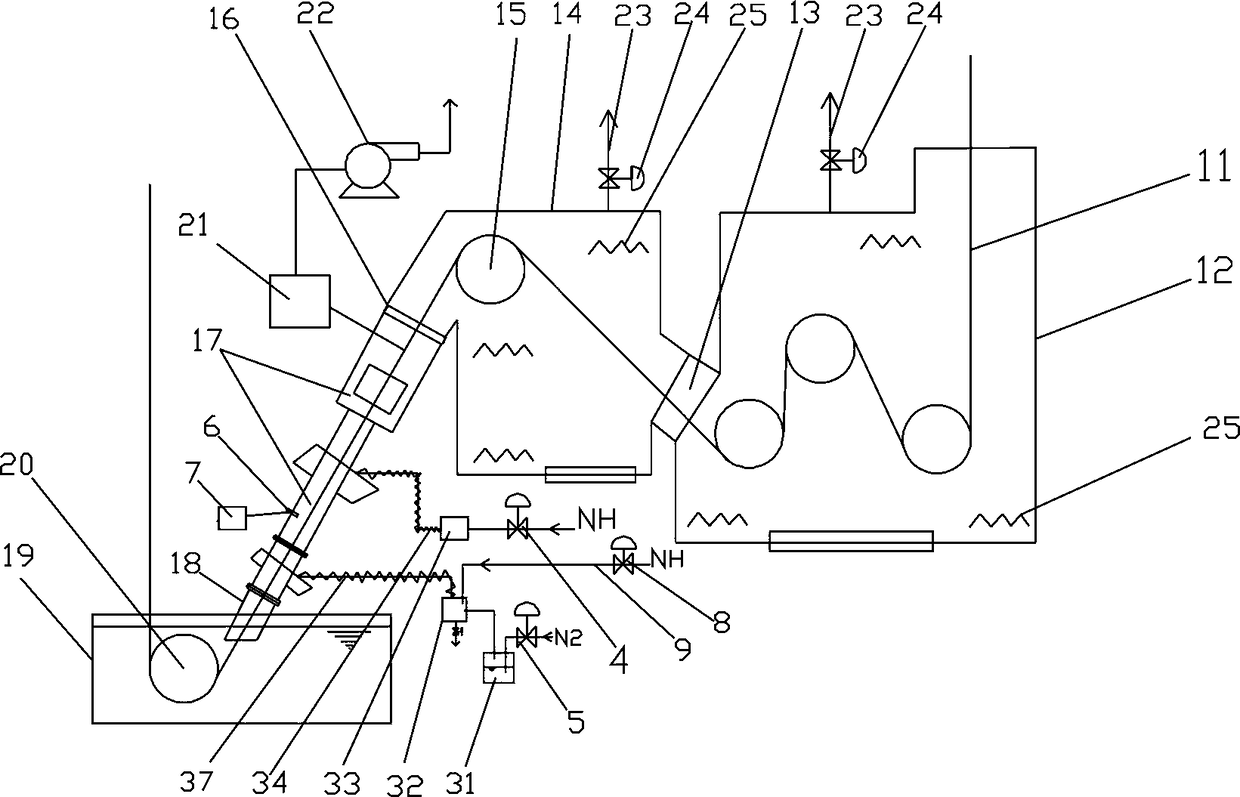

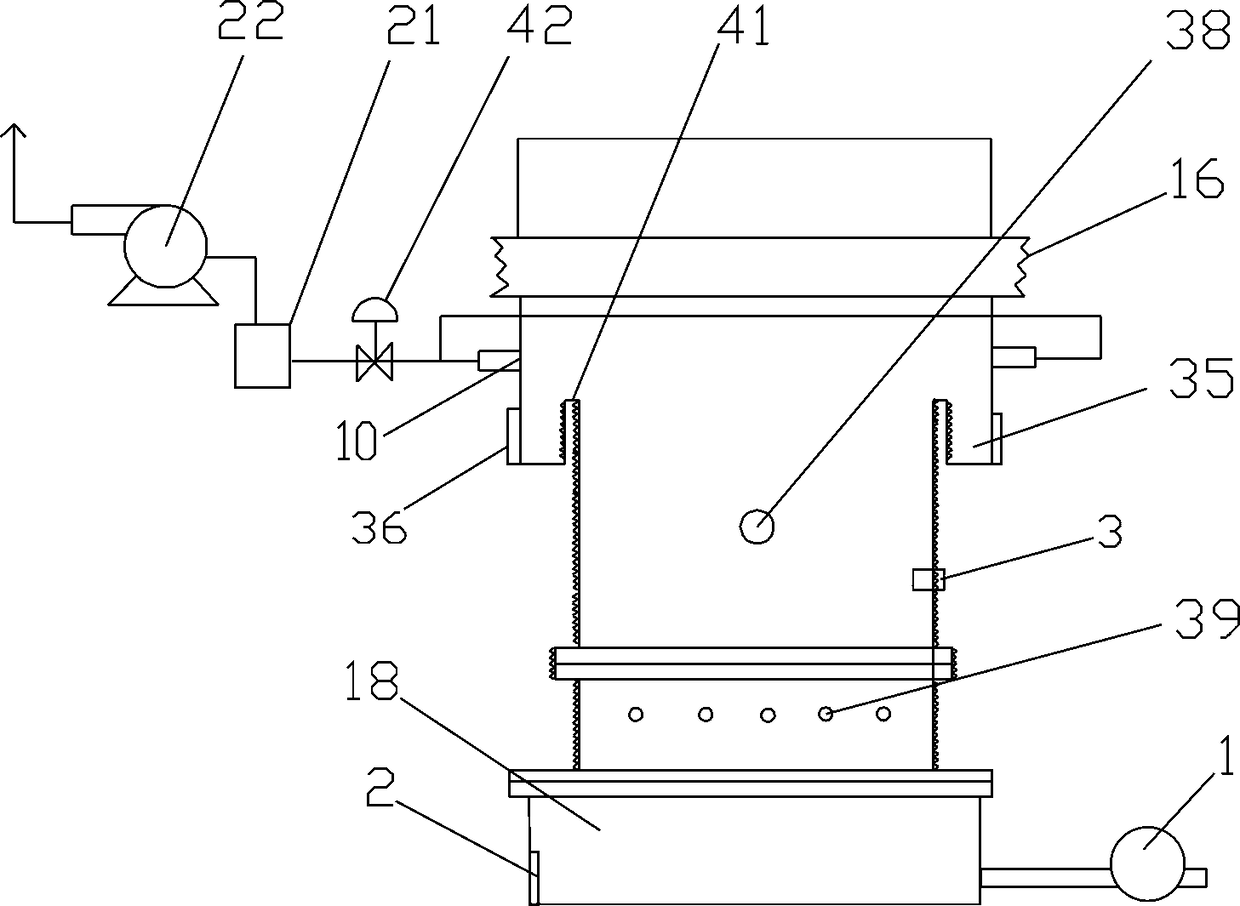

[0025] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. And the features in the embodiments can be combined with each other.

[0026] Such as figure 1 , 2As shown, a continuous hot-dip galvanizing system for strip steel includes: pre-plating tension roll chamber 12, sealing device 13, pre-plating turning roll chamber 14, pre-plating turning roll 15, expansion joint 16, hot-dip coating channel 17 , exhaust fan 22, zinc ash filter 21, furnace nose 18, protective gas supply device (not shown in the figure), release pipeline 23, release control solenoid valve 24, zinc pot sinking roller device 20 and zinc pot 19, zinc pot The lower end of the pot sinking roller device 20 and the furnace nose 18 is immersed in the zinc liquid in the zinc pot 19, the upper end of the furnace nose 18 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com