Tamping rod additionally provided with torsional spring device and used for railway ballast tamping

A technology of tamping rods and torsion springs, applied to roads, tracks, ballast layers, etc., can solve problems such as poor operating comfort and easy breakage of flexible shafts, and achieve the effects of reasonable structure, good tamping effect, and comfortable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

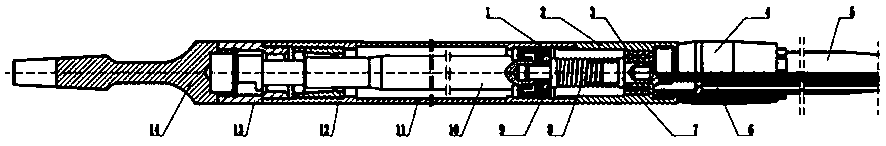

[0007] combine figure 1 The details and working process of the present invention are described in detail. A torsion spring device consisting of connecting sleeve 2, bearing 3, I torsion spring joint 7, torsion spring 8 and II torsion spring joint 9 is installed in the flexible shaft tamping rod; the front end of the connection sleeve 2 is connected to the rod shell 11, and the rear end is connected to Hose joint 4; I torsion spring joint 7 and II torsion spring joint 9 are made with the same screw thread as torsion spring 8 after tightening, and are connected with torsion spring 8 through this thread; I torsion spring joint 7 is equipped with bearing 3 , and the inner flexible shaft 6 is compressed; II torsion spring joint 9 is threaded with the roller cone 10, and the roller cone 10 is equipped with a large clearance bearing 1. One end of the hose 5 is connected to the hose joint 4, the rod shell 11 is threaded to the pick body 13, and the pick body 13 is threaded to the pic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com