Connection joint of steel frame with ALC external wall panel

A technology for connecting nodes and external wall panels, applied in the direction of walls, buildings, building components, etc., can solve the problems of complex installation, many parts, and complicated construction operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

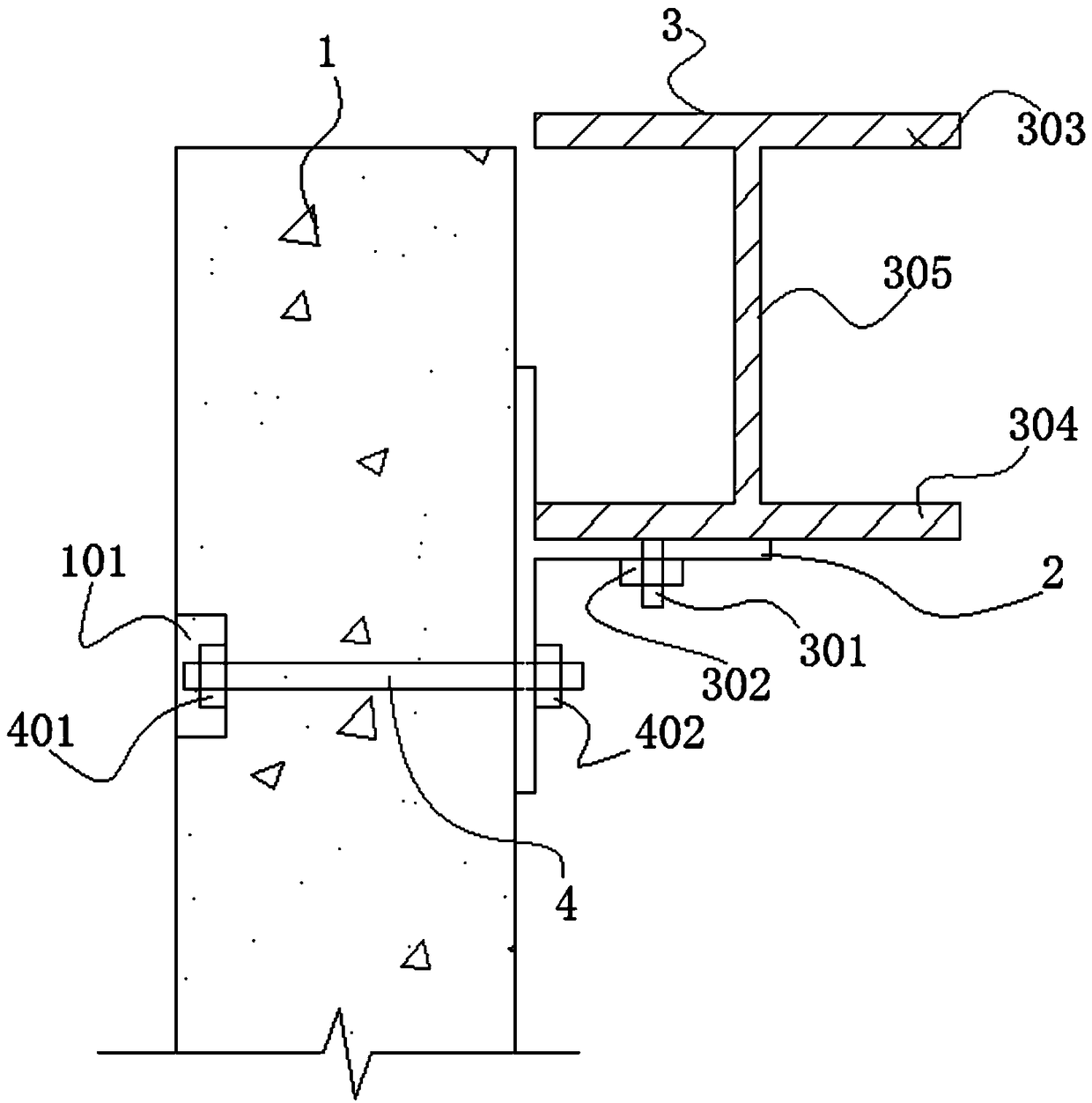

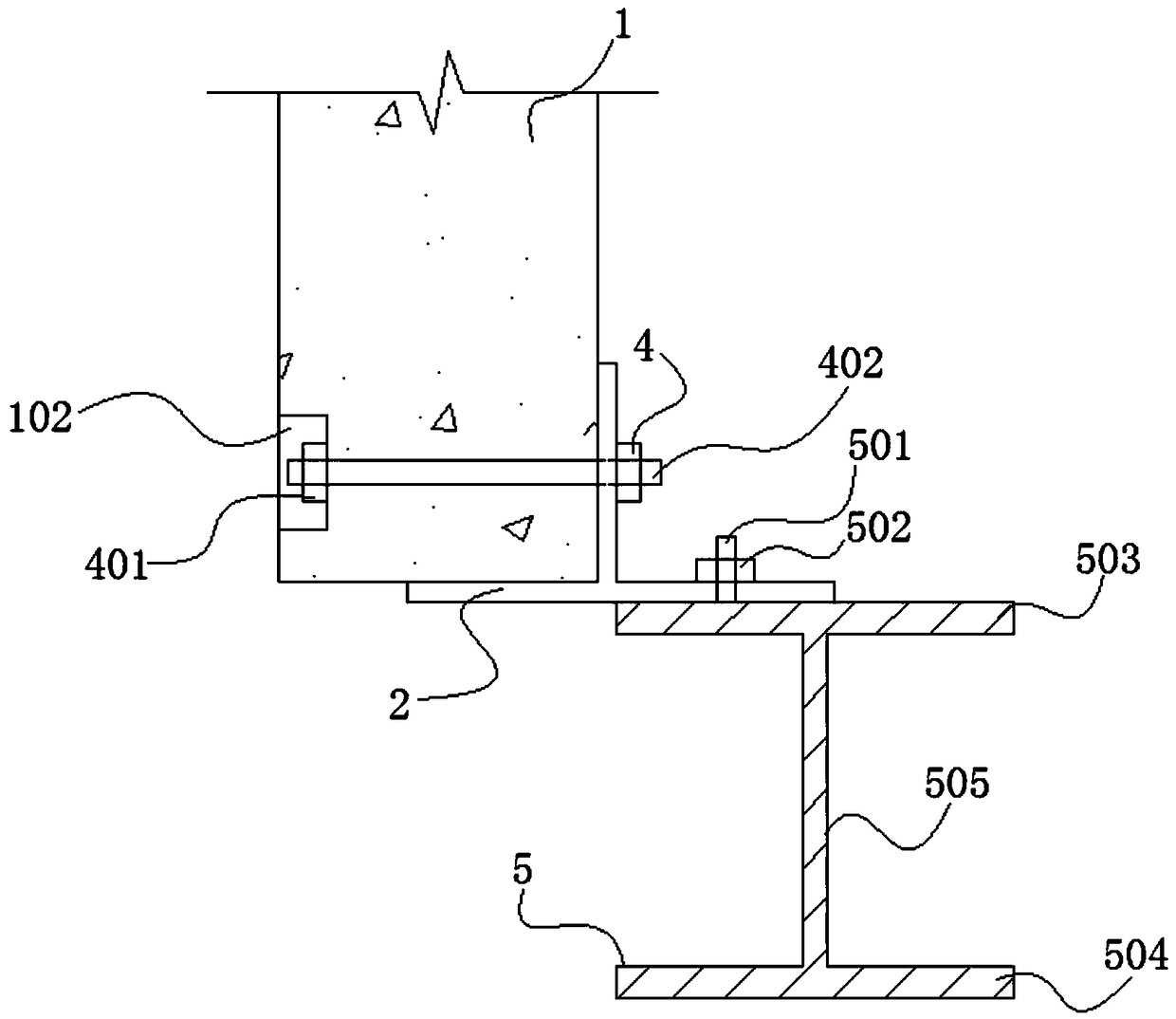

[0048] A steel frame connection node with ALC external wall panels, that is, in the steel frame connection node with ALC vertical external wall panels:

[0049] An ALC external wall panel I1 is equipped with several connecting pieces 2 .

[0050] An ALC external wall panel I1 is connected with the upper and lower I-beams in the building frame. Wherein, the upper one is marked as the upper I-shaped steel beam 3, and the lower one is marked as the lower I-shaped steel beam 5, and the two are parallel to each other.

[0051] The connector 2 includes a vertical plate 201 and a bottom plate. The two sides of the bottom plate are respectively an upper plate surface and a lower plate surface, and the lower plate surface is marked as an E surface 223 . The vertical plate 201 is vertically fixed on the upper surface of the bottom plate. The vertical plate 201 divides the upper surface of the bottom plate into two parts, one side of the vertical plate 201 is the C surface 2021 , and ...

Embodiment 2

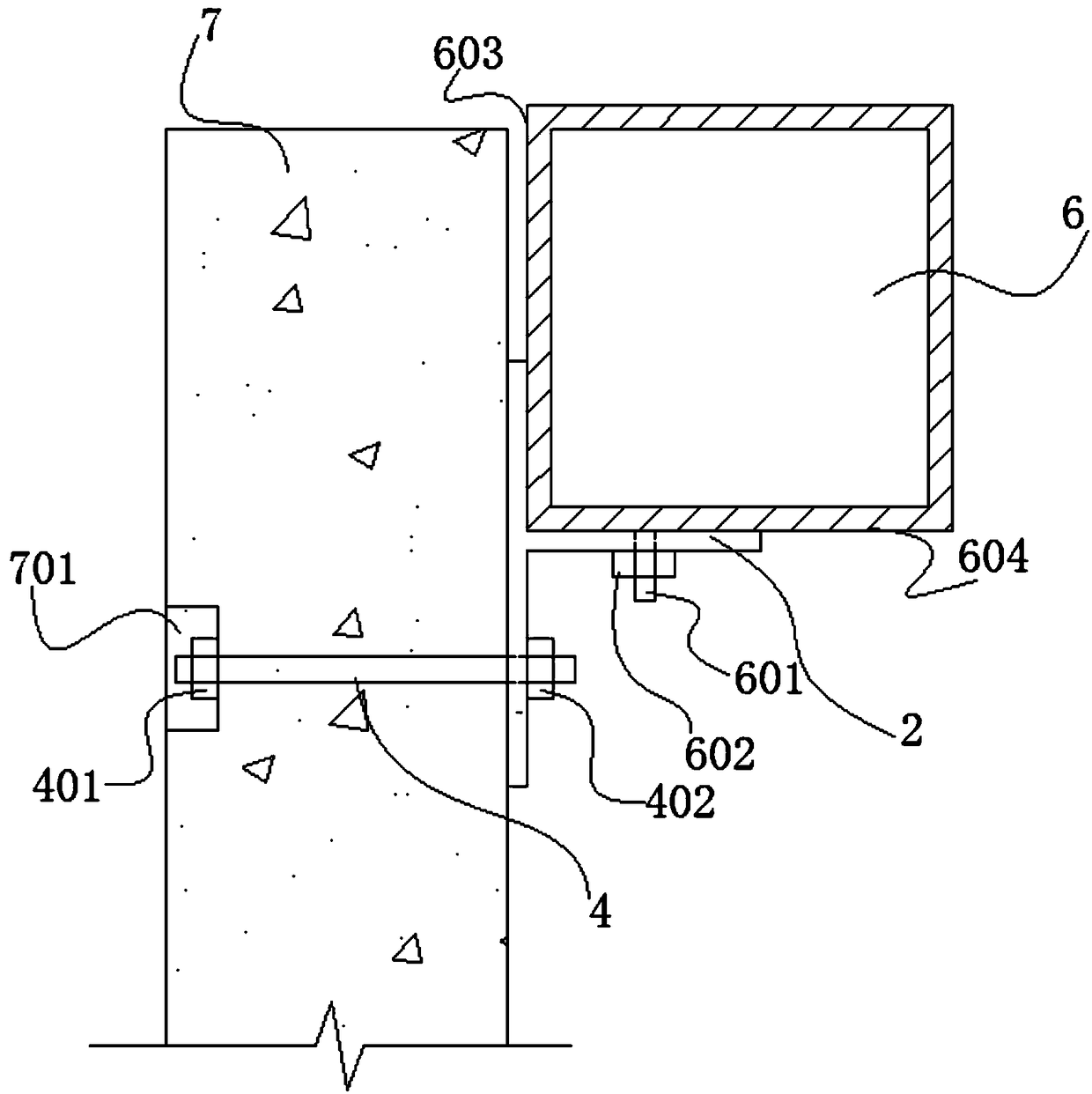

[0057] In the connection node of the steel frame with ALC horizontal external wall panels, the same connection piece as that in Embodiment 1 is used.

[0058] One ALC external wall panel II7 is equipped with several connecting pieces 2 .

[0059] An ALC external wall panel II7 is connected with two left and right rectangular steel columns 6 in the building frame.

[0060] The side of the rectangular steel column 6 facing the ALC external wallboard II7 is designated as the F side 603 . The facing faces of the two rectangular steel columns 6 are marked as G faces 604 .

[0061] Several screw rods III601 are welded on the G surface 604 . The number of the screw rods III601 is the same as the number of the connectors 2 .

[0062] During assembly, a rectangular steel column 6 is equipped with at least two connecting pieces 2 . The C surfaces 2021 of these connectors 2 are in contact with the F surfaces 603 of the rectangular steel columns 6 . The A surface 2011 of these connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com