Rotary steerable drilling system with low cost, high build-up rate and high mechanical drilling speed

A rotary steerable drilling and rotary steerable technology, applied in directional drilling, drilling equipment, driving devices for drilling in wellbore, etc., can solve the problems of high cost, poor reliability, complex structure, etc., to ensure power supply and communication The effect of stability, low manufacturing cost and low processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

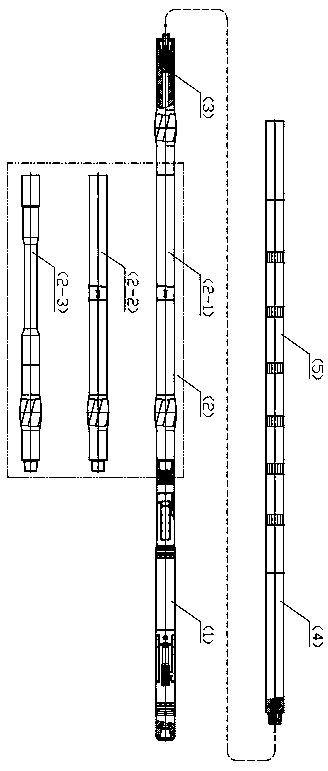

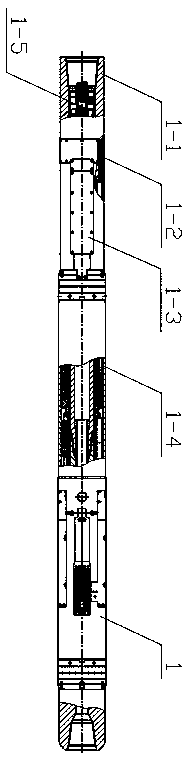

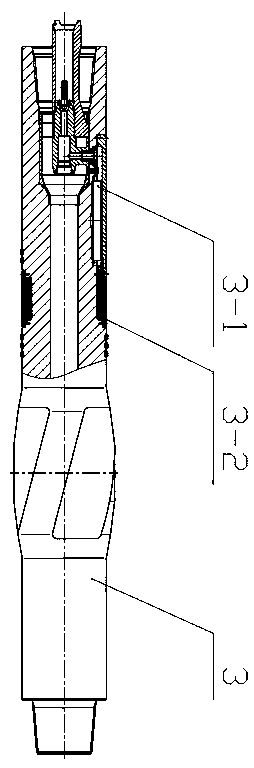

[0029] see figure 1 , a rotary steerable drilling system with low cost, high build-up rate and high ROP, including a rotary steerable drilling tool 1, a downhole dynamic drilling tool 2, a wireless short transmission receiving sub 3, MWD4 and LWD5. The upper end of the said rotary steerable drilling tool 1 is threadedly connected with the lower end of the downhole power drilling tool 2, and the upper end of the downhole power drilling tool 2 is connected with the lower end of the wireless short transmission transceiver nipple 3 by threads, and the wireless short transmission short transmission short The upper end of section 3 is connected with the lower end of MWD 4 by threads, and the upper end of MWD4 is connected with the lower end of LWD5 by threads. In this way, a rotary steerable drilling system with double power mechanism and double guide devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com