Automatic locking and leveling system and method of vehicle

An automatic locking and vehicle technology, applied in vehicle maintenance, lifting vehicle accessories, fluid pressure actuation devices, etc., can solve the problems of increasing system power and heat generation, increasing system power consumption, and throttling loss, etc., to achieve The effect of reducing flow demand, reasonable action sequence, and accelerating no-load extension speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

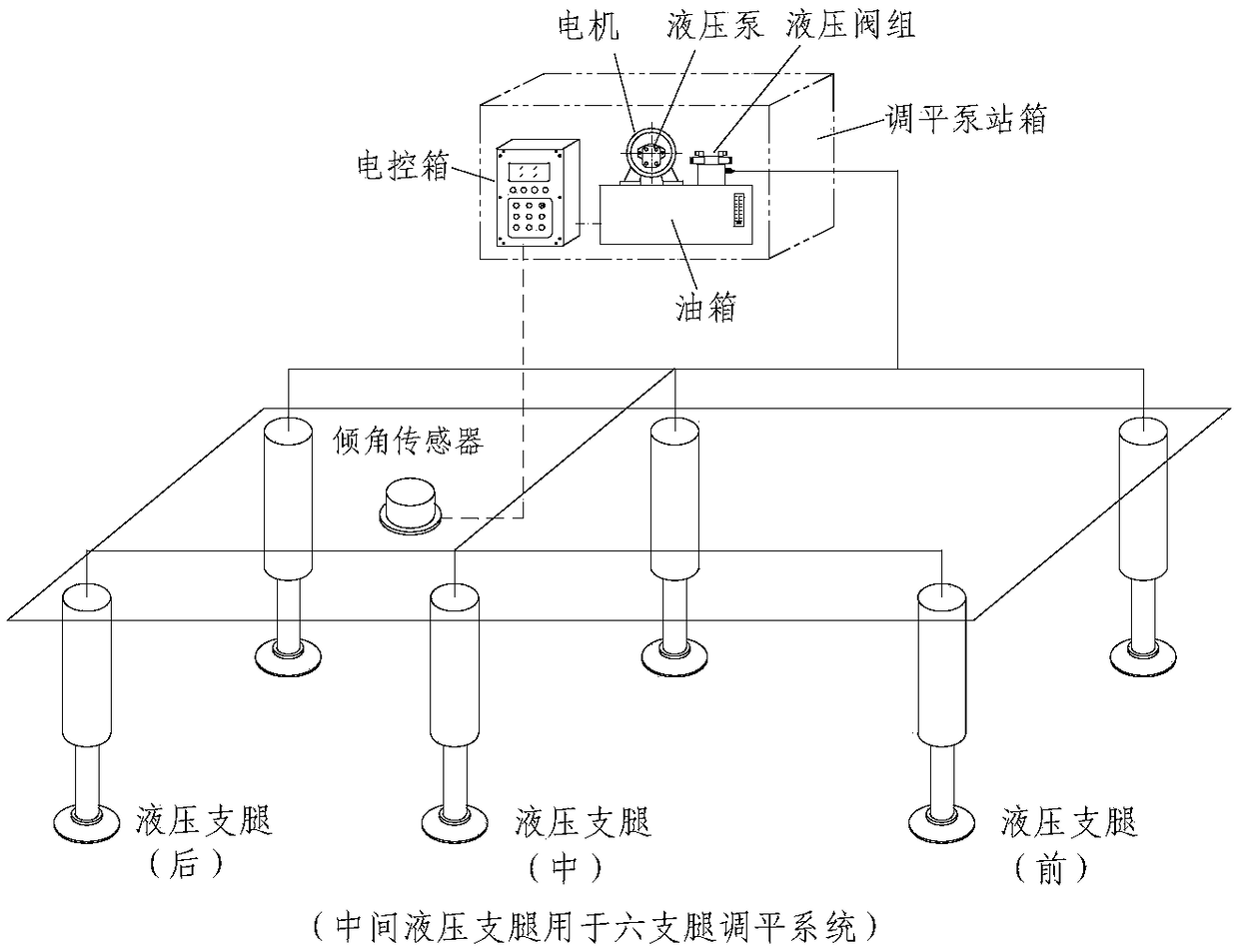

[0060] Four-legged vehicle sub-locking and leveling system such as figure 1 As shown, it is composed of leveling pump station box, hydraulic outrigger, inclination sensor and oil circuit. The hydraulic outriggers are symmetrically installed on the side of the vehicle chassis, the leveling pump station box is installed on the side of the vehicle chassis, the electric control box is installed inside the leveling hydraulic box, the inclination sensor is installed horizontally on the chassis, and the two direction axes of the inclination sensor Parallel to the transverse and longitudinal directions of the vehicle, the longitudinal direction of the vehicle is the direction from the front to the rear, the transverse direction of the vehicle is perpendicular to the longitudinal direction of the vehicle, and the hydraulic oil circuit and cables are arranged on the chassis.

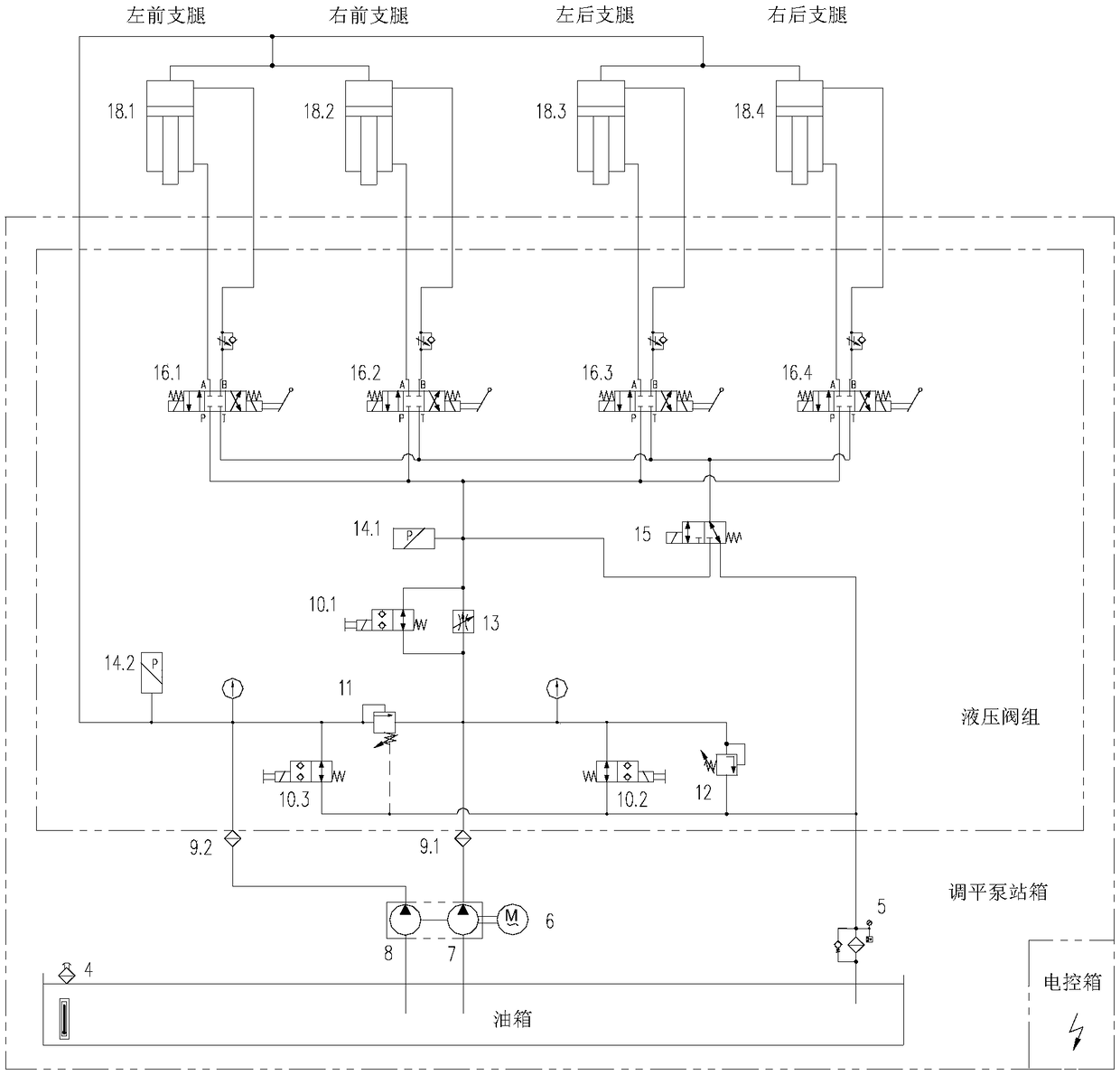

[0061] The four-leg vehicle sub-locking and leveling system has 4 hydraulic outriggers in total, which are 2 fr...

Embodiment 2

[0101] Six-leg vehicle locking and leveling system such as figure 1 As shown, it is composed of leveling pump station box, hydraulic outrigger, inclination sensor and oil circuit and other equipment. The 6 hydraulic outriggers are symmetrically installed on the side of the vehicle chassis, the leveling pump station box is installed on the side of the vehicle chassis, the electric control box is installed inside the leveling hydraulic box, the inclination sensor is installed horizontally on the chassis, and the hydraulic pipelines and cables are arranged on the chassis. The functions of other components are the same as the above-mentioned four-leg leveling system.

[0102] The difference from the four-legged vehicle locking and leveling system in Embodiment 1 is that a pair of intermediate hydraulic outriggers are added between the front and rear outriggers to improve the stability of the vehicle or platform after leveling and improve the structural stress. All six hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com