A kind of aluminum alloy petroleum liquefied gas bottle body and preparation method thereof

A technology for petroleum liquefied gas and liquefied gas cylinders, which is used in gas/liquid distribution and storage, mechanical equipment, fluid handling, etc. The effect of preventing corrosion, improving service life and reducing the weight of the bottle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

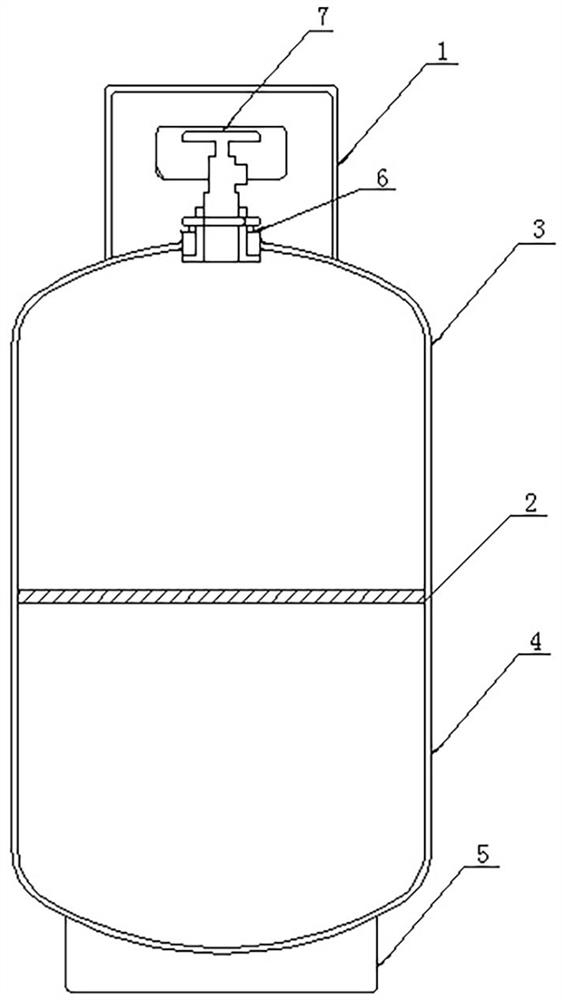

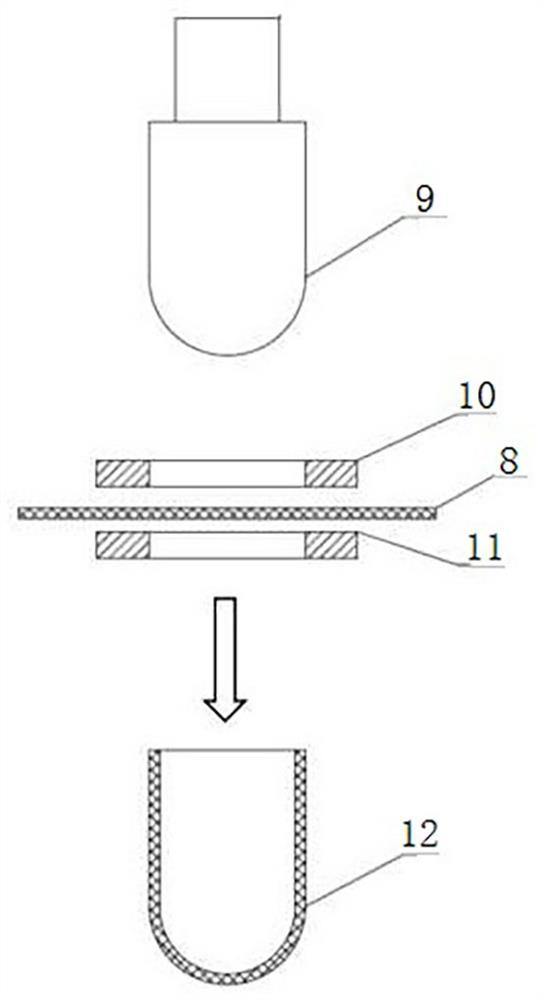

[0024] The preparation method of the aluminum alloy liquefied petroleum gas cylinder of the present invention specifically comprises:

[0025] A. Blank heat treatment: Cut the raw material into a disc-shaped structural blank 8, put the blank 8 into a heating furnace and heat it to 200°C~450°C, and the heating and holding time is 30min~100min;

[0026] B. Blank stamping and stretching: the blank 8 is placed between the upper drawing die 10 and the lower drawing die 11, and the stamping and stretching method is used to stamp and stretch the heated blank through the extrusion head 9 of the hydraulic press to become The rough blank 12 of the "U" shaped bottle (that is, the rough blank of the upper bottle body 3 and the lower bottle body 4);

[0027] C. Solid solution aging treatment of the rough body of the bottle body: the rough body of the bottle body 12 (that is, the rough body of the upper bottle body 3 and the rough body of the lower bottle body 4) is first subjected to a sol...

Embodiment 1

[0039] Example 1: 1) Calculate the raw material size required for the preparation according to the size of the petroleum liquefied gas cylinder to be prepared, and cut the aluminum alloy round bar ingot into a disc-shaped structural blank 8 of the required thickness according to the calculated size. The diameter of 8 is 100mm~700mm;

[0040] 2) Put the cut blank 8 into a heating furnace with a furnace temperature of 200°C~450°C and heat for 30min~100min;

[0041] 3) Apply lubricant to the extrusion head 9 of the extruder, the outside of the heated billet 8, the inner walls of the upper drawing die 10 and the lower drawing die 11, and then put the billet 8 on the upper drawing die 10 Between the upper drawing die 10 and the lower drawing die 11, press the outer edge of the billet 8 with the lower drawing die 11, and then press the central part of the billet 8 that has been heated by the extrusion head 9 by the stamping method. Stamping-stretching, the extrusion head 9 is kept ...

Embodiment 2

[0046] Example 2: 1) Calculate the raw material size required for the preparation according to the size of the liquefied petroleum gas cylinder to be prepared, and cut the aluminum alloy round bar ingot into a disc-shaped structural blank 8 of the required thickness according to the calculated size. The diameter of 8 is 100mm~700mm;

[0047] 2) Put the cut blank 8 into a heating furnace with a furnace temperature of 200°C~450°C and heat for 30min~100min;

[0048] 3) Apply lubricant to the extrusion head 9 of the extruder, the outside of the heated billet 8, the inner walls of the upper drawing die 10 and the lower drawing die 11, and then put the billet 8 on the upper drawing die 10 Between the upper drawing die 10 and the lower drawing die 11, press the outer edge of the billet 8 with the lower drawing die 11, and then press the central part of the billet 8 that has been heated by the extrusion head 9 by the stamping method. Stamping-stretching, the extrusion head 9 is kept ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com