A combined bottle body manufacturing method for an aluminum alloy liquefied petroleum gas bottle

A technology of liquefied gas cylinders and manufacturing methods, which is applied in the manufacture of container structures, gas/liquid distribution and storage, fluid treatment, etc., can solve the problems of poor corrosion resistance of steel materials, high road transportation costs, and high labor intensity. High pressure, superior physical and chemical properties, reduce the effect of manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

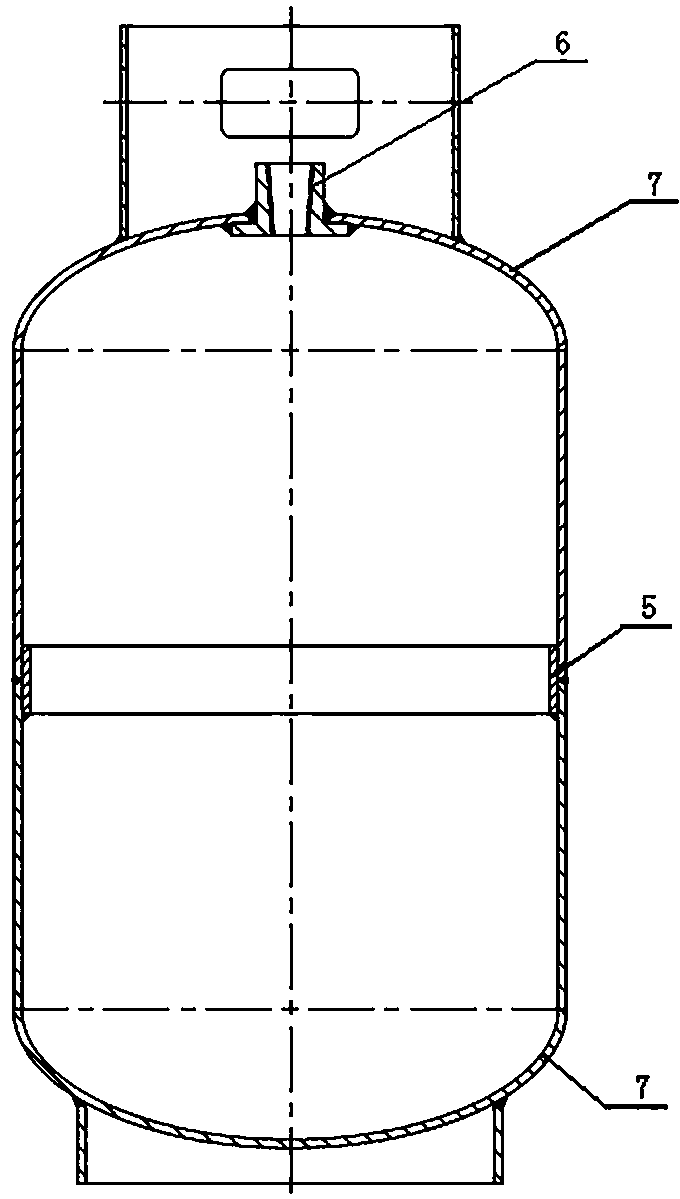

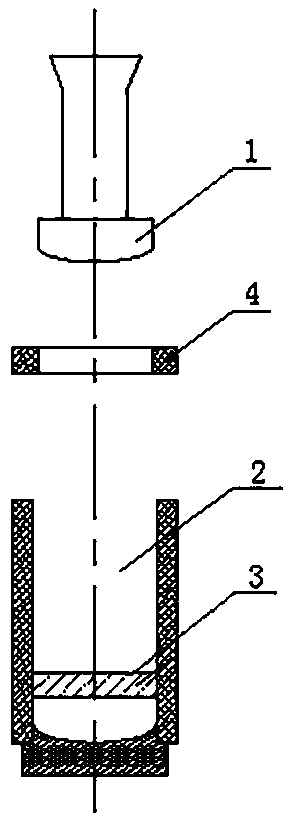

[0033] Example 1: 1) Calculate the raw material size required for the preparation according to the size of the petroleum liquefied gas cylinder to be prepared, and cut the aluminum alloy round bar ingot into a round slab of required thickness according to the calculated size, so that the round The slab becomes the bottle body blank 3 for preparing petroleum liquefied gas cylinders;

[0034] 2) Put the cut bottle body blank 3 into a heating furnace with a furnace temperature of 200°C~400°C and heat for 30min~90min;

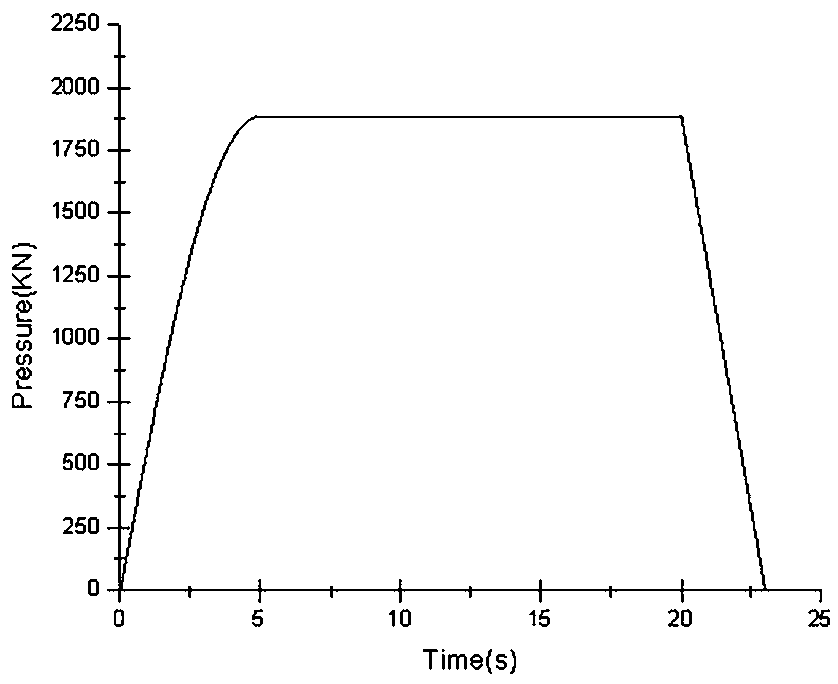

[0035] 3) Apply lubricant on the pressure head 1 of the extruder, the outside of the bottle body blank 3 and the inner wall of the mold cavity 2, and then put the bottle body blank 3 in the mold cavity 2, and the pressure head 1 with 3~ Press down the bottle body blank 3 at a descending speed of 5mm / s, so that the bottle body blank 3 begins to slide and deform along the surface of the mold cavity 2, and the pressure of the pressing head 1 gradually increases with t...

Embodiment 2

[0040]Example 2: 1) Calculate the raw material size required for the preparation according to the size of the petroleum liquefied gas cylinder to be prepared, and cut the aluminum alloy round bar ingot into a circular slab of required thickness according to the calculated size, so that the round The slab becomes the bottle body blank 3 for preparing petroleum liquefied gas cylinders;

[0041] 2) Put the cut bottle body blank 3 into a heating furnace with a furnace temperature of 200°C~400°C and heat for 30min~90min;

[0042] 3) Apply lubricant on the pressure head 1 of the extruder, the outside of the bottle body blank 3 and the inner wall of the mold cavity 2, and then put the bottle body blank 3 in the mold cavity 2, and the pressure head 1 with 3~ Press down the bottle body blank 3 at a descending speed of 5mm / s, so that the bottle body blank 3 begins to slide and deform along the surface of the mold cavity 2, and the pressure of the pressing head 1 gradually increases with...

Embodiment 3

[0047] Example 3: 1) Calculate the raw material size required for the preparation according to the size of the petroleum liquefied gas cylinder to be prepared, and cut the aluminum alloy round bar ingot into a round slab of required thickness according to the calculated size, so that the round The slab becomes the bottle body blank 3 for preparing petroleum liquefied gas cylinders;

[0048] 2) Put the cut bottle body blank 3 into a heating furnace with a furnace temperature of 200°C~400°C and heat for 30min~90min;

[0049] 3) Apply lubricant on the pressure head 1 of the extruder, the outside of the bottle body blank 3 and the inner wall of the mold cavity 2, and then put the bottle body blank 3 in the mold cavity 2, and the pressure head 1 with 3~ Press down the bottle body blank 3 at a descending speed of 5mm / s, so that the bottle body blank 3 begins to slide and deform along the surface of the mold cavity 2, and the pressure of the pressing head 1 gradually increases with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com