Fluid damper device and apparatus with damper

一种流体阻尼、阻尼室的技术,应用在流体阻尼装置及带阻尼的设备领域,能够解决旋转负载大等问题,达到变形的可能性小、抑制阻尼性能的不均、提高尺寸精度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

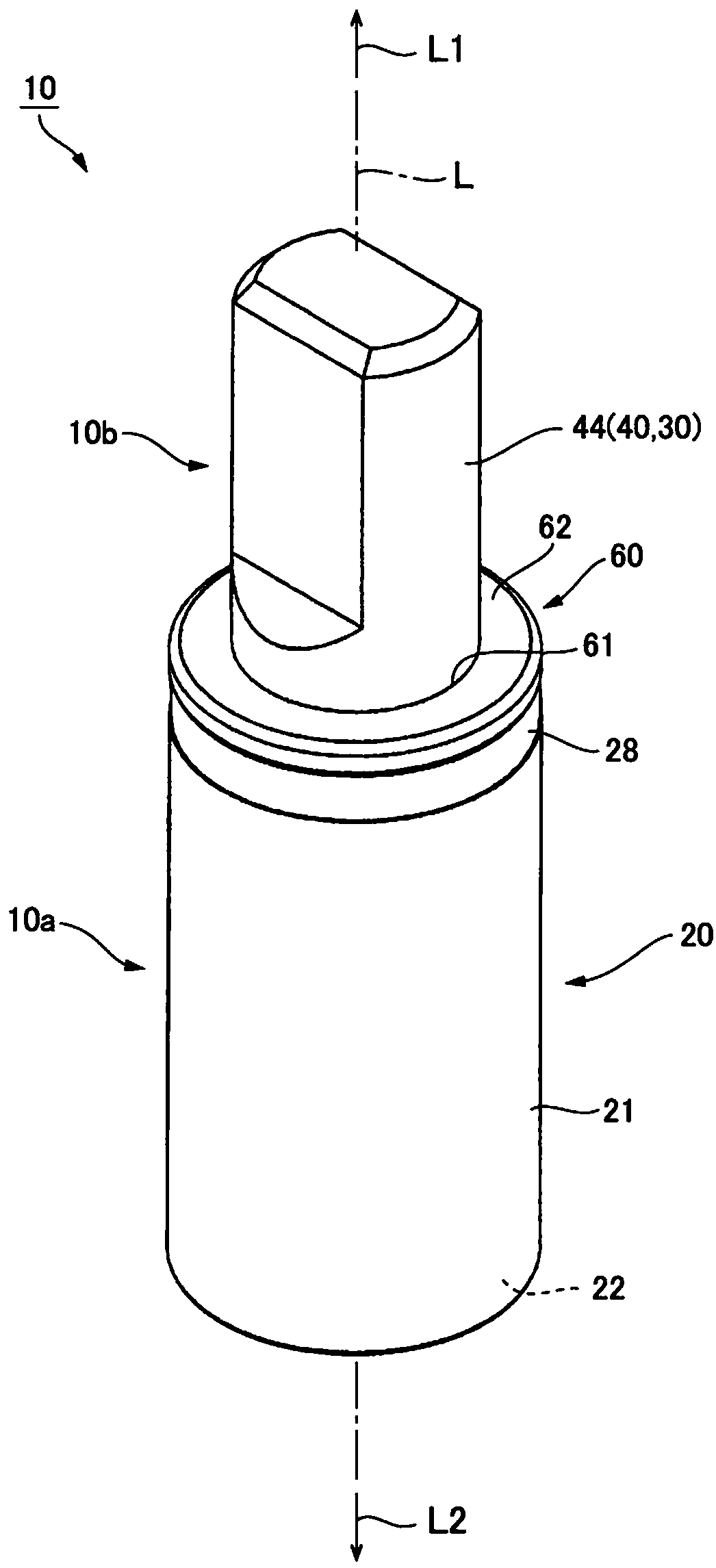

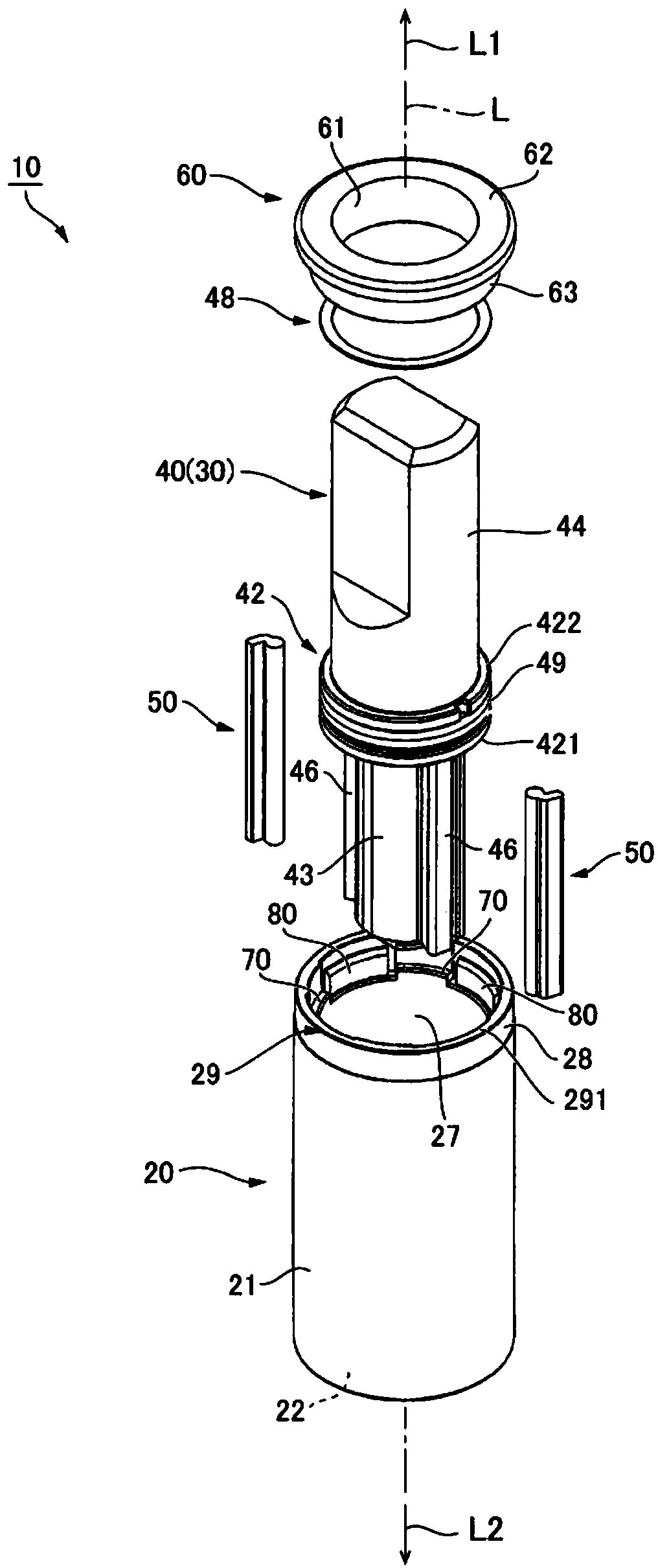

[0115] Hereinafter, modes for implementing the present invention will be described with reference to the drawings. Furthermore, in the following description, the direction in which the rotating shaft 40 of the rotor 30 extends is referred to as the direction of the axis L, and the side where the rotating shaft 40 protrudes from the housing 20 in the direction of the axis L is referred to as one side L1. The side opposite to the side where the rotating shaft 40 protrudes from the casing 20 is described as the other side L2.

[0116] (device with damping)

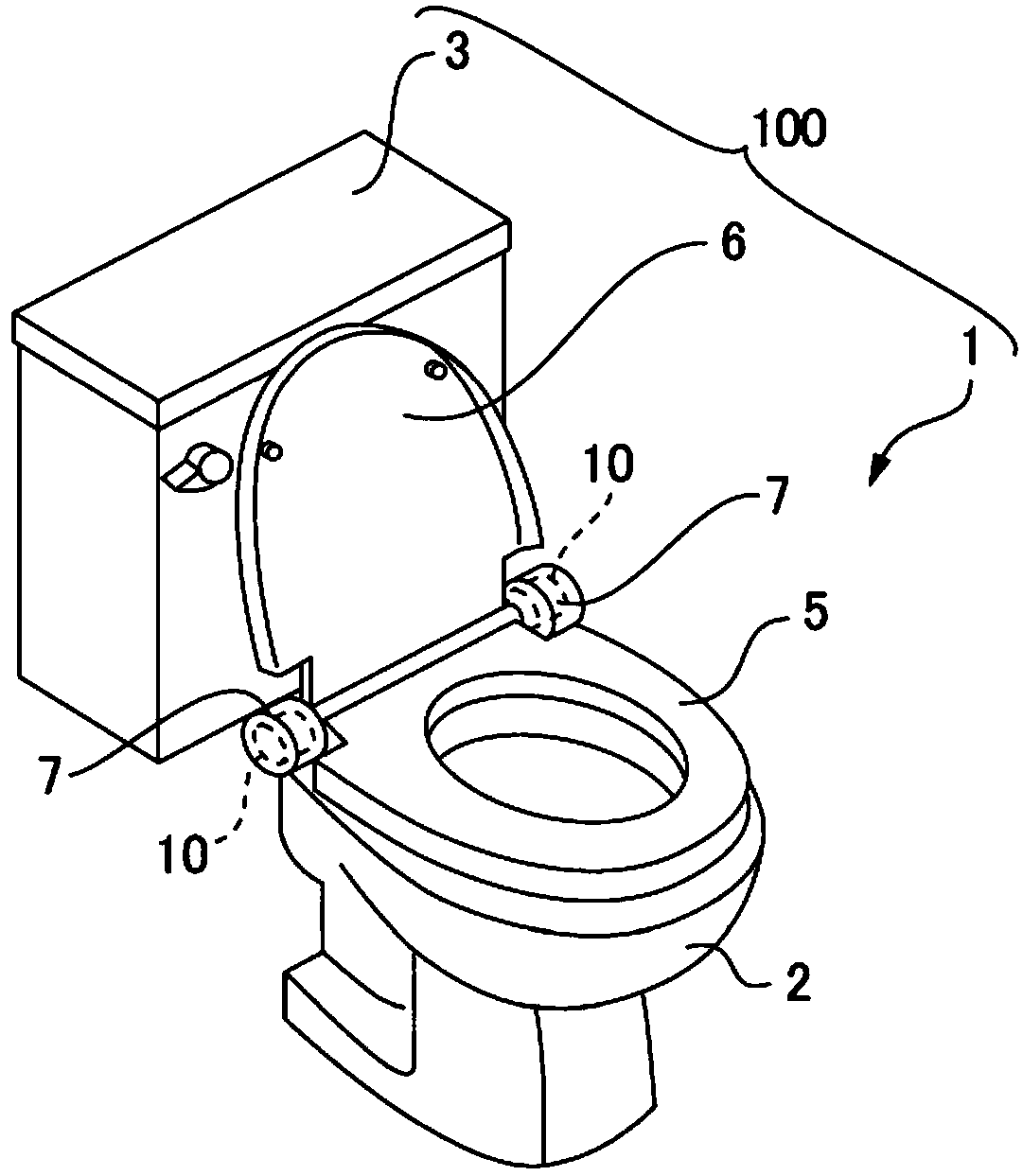

[0117] figure 1It is an explanatory diagram of a western-style toilet unit 100 including a western-style toilet 1 equipped with a fluid damping device 10 to which the present invention is applied. figure 1 The western-style toilet unit 100 shown includes: a western-style toilet 1 (equipment with damping) and a sink 3 . The western-style toilet 1 includes a toilet body 2 (device body), a resin toilet seat 5 (opening and clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com