Stirring container

A technology for stirring containers and stirring blades, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, chemical instruments and methods, etc. It can solve the problems of unsatisfactory material quality, insufficient material mixing uniformity and low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

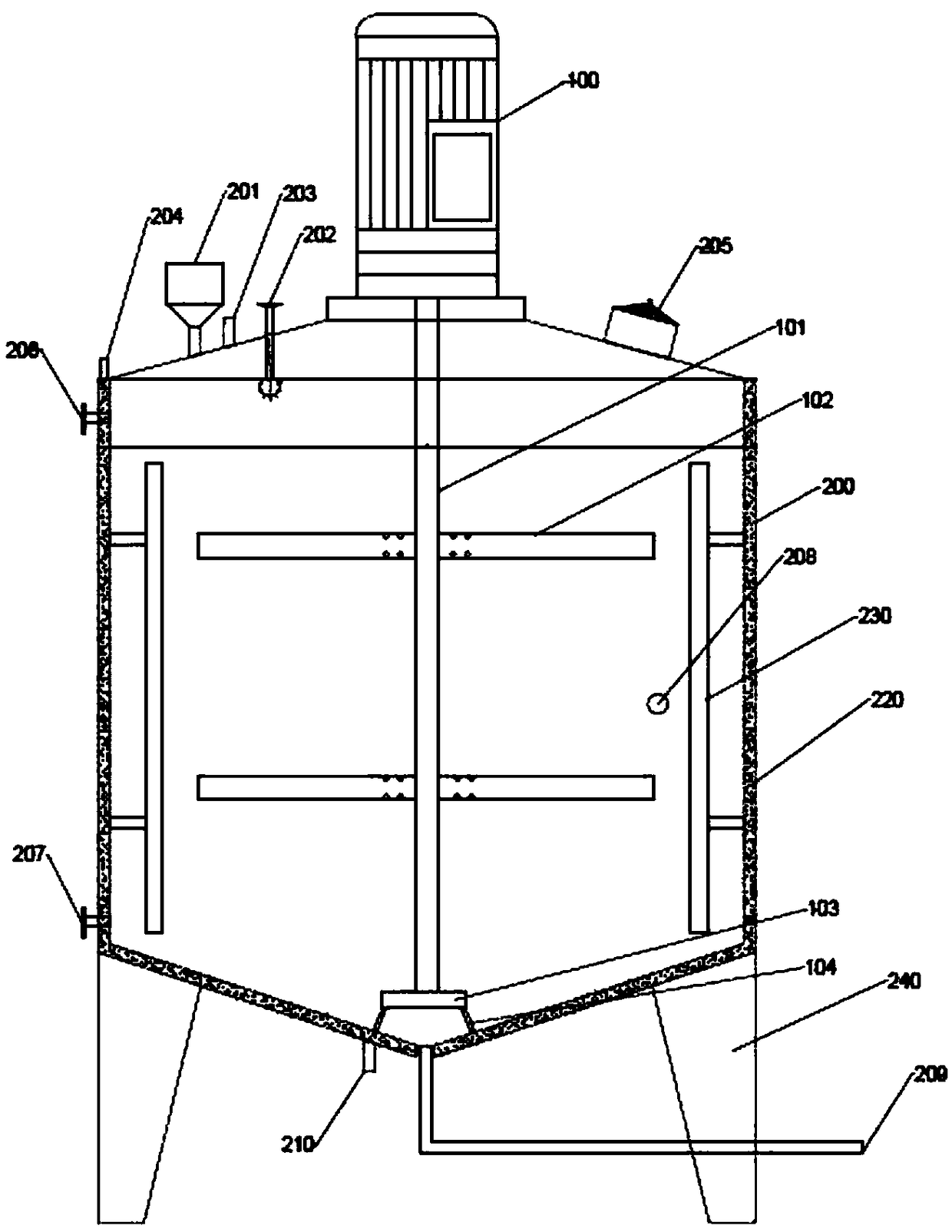

[0017] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0018] What needs to be specially explained here is the structural schematic diagram of the stirring vessel listed in the present invention, which is only an exemplary structural diagram provided for the convenience of explaining the problem, and it is not the only correct implementation mode of the present invention, and it should not be understood as protecting the present invention. Scope limitation.

[0019] For better illustrating the present invention, facilitate understanding technical scheme of the present invention, typical but non-limiting embodiment of the present invention is as follows:

[0020] The stirring container of the present invention is mainly used for feed processing, especially the processing of pre-digested feed, and of course it can also be used in technical fields such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com