A zinc tungstate/stannous tungstate composite photocatalyst with core-shell structure and its preparation and application

A technology of core-shell structure and complex light, which is applied in the direction of physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, heterogeneous catalyst chemical elements, etc., and can solve the problems of few organic pollutants research , to achieve the effect of simple preparation method, easy operation and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 One-dimensional ZnWO 4 Preparation of nanorods

[0027] 0.90g Zn(NO 3 ) 2 •6H 2 O and 1.0 g Na 2 WO 4 • 2H 2 O was added to the lining of the 50ml reactor, and 28ml of deionized water was added, and the stirring was continued for 30 minutes, then the pH was adjusted to 7 with 0.5 M NaOH, and the stirring was continued for 1 hour; the stirred solution was transferred to a 50ml autoclave , hydrothermal reaction at 180°C for 48 hours; take it out after the reaction, cool to room temperature in air, centrifuge and dry at 80°C to obtain ZnWO 4white powder, number 1.

Embodiment 2

[0029] 1) One-dimensional ZnWO 4 Preparation of nanorods

[0030] 0.90g Zn(NO 3 ) 2 •6H 2 O and 1.0 g Na 2 WO 4 • 2H 2 O was added to the lining of the 50ml reactor, and 28ml of deionized water was added, and the stirring was continued for 30 minutes, then the pH was adjusted to 7 with 0.5 M NaOH, and the stirring was continued for 1 hour; the stirred solution was transferred to a 50ml autoclave , hydrothermal reaction at 180°C for 48 hours; take it out after the reaction, cool to room temperature in air, centrifuge and dry at 80°C to obtain ZnWO 4 white powder;

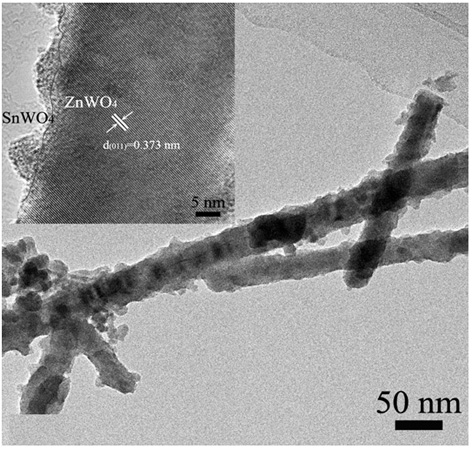

[0031] 2) Core-shell structure ZnWO 4 @SnWO 4 Preparation of Composite Photocatalyst

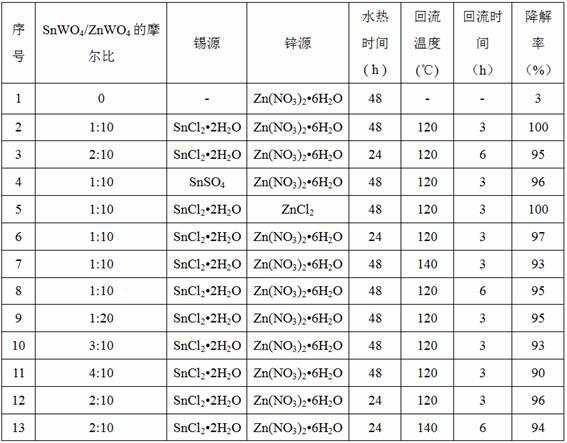

[0032] 0.63g ZnWO 4 and 80ml deionized water were added to a 150ml Erlenmeyer flask, then 0.1 M HCl was added to adjust the pH to 5, and then 0.045g SnCl was added 2 • 2H 2 O and 1 ml of 0.2 M Na 2 WO 4 • 2H 2 O, to regulate SnWO 4 / ZnWO 4 The molar ratio is 1:10, stirred and refluxed at 120°C for 3 hours, then ce...

Embodiment 3

[0034] 1) One-dimensional ZnWO 4 Preparation of nanorods

[0035] 0.90g Zn(NO 3 ) 2 •6H 2 O and 1.0 g Na 2 WO 4 • 2H 2 O was added to the lining of the 50ml reactor, and 28ml of deionized water was added, and the stirring was continued for 30 minutes, then the pH was adjusted to 7 with 0.5 M NaOH, and the stirring was continued for 1 hour; the stirred solution was transferred to a 50ml autoclave , hydrothermal reaction at 160°C for 24 hours; take it out after the reaction, cool to room temperature in the air, centrifuge and dry at 80°C to obtain ZnWO 4 white powder;

[0036] 2) Core-shell structure ZnWO 4 @SnWO 4 Preparation of Composite Photocatalyst

[0037] 0.63g ZnWO 4 and 80ml deionized water were added to a 150ml Erlenmeyer flask, then 0.1 M HCl was added to adjust the pH to 5, and then 0.09g SnCl was added 2 • 2H 2 O and 2 ml of 0.2 M Na 2 WO 4 • 2H 2 O, to regulate SnWO 4 / ZnWO 4 The molar ratio is 2:10, stirred and refluxed at 120°C for 6 hours, then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com