Automatic paper crushing machine with staple removal structure and staple removal method thereof

A paper shredder, automatic technology, applied in the direction of grain processing, etc., can solve the problems of inability to shred documents, inability to inhale, and troublesome and time-consuming removal of staples, etc., to achieve the effects of prolonging service life, preventing damage, and saving economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

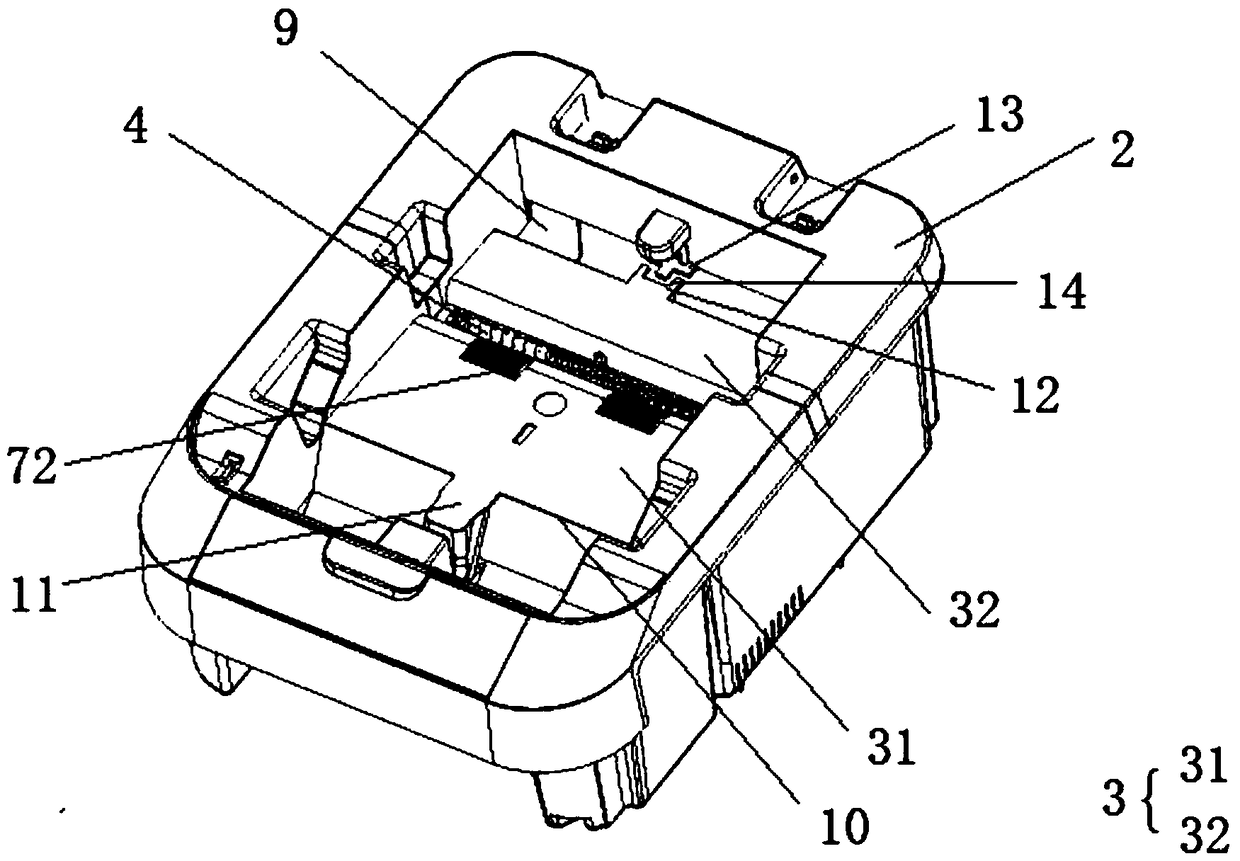

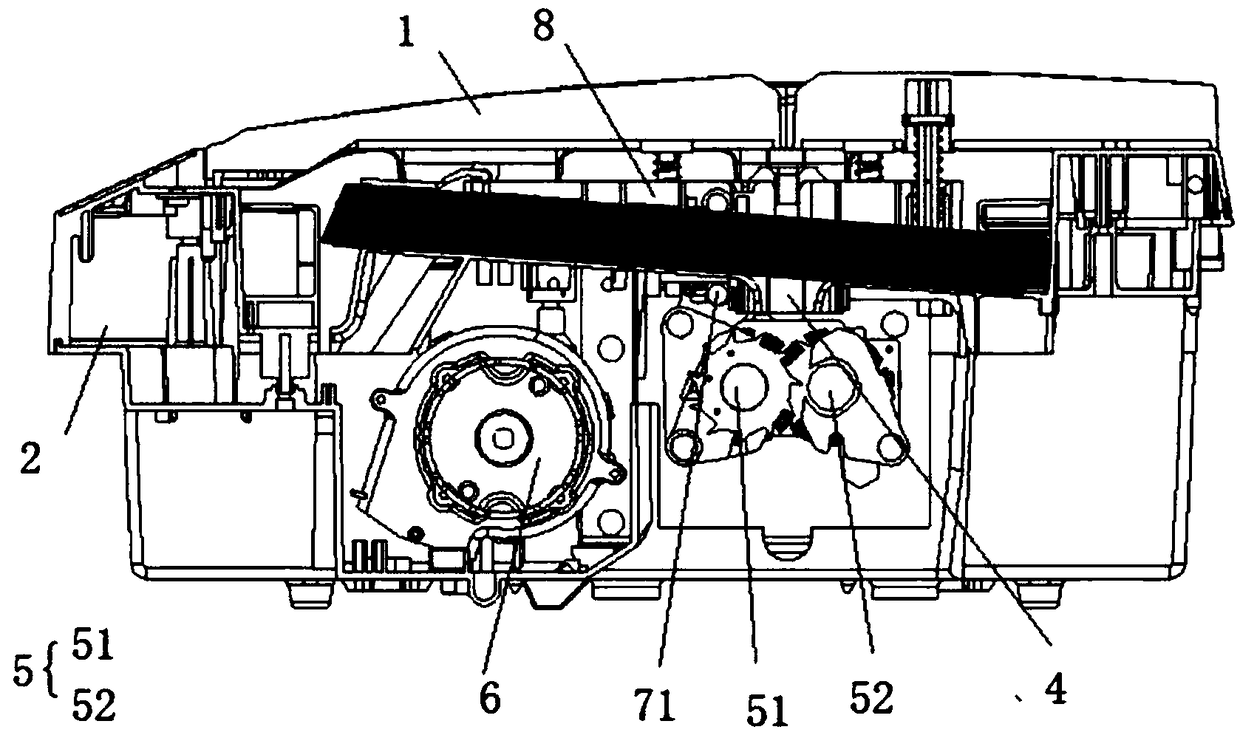

[0094] like figure 1 As shown, the present invention discloses an automatic paper shredder with a nail-shaving structure, including a machine cover 1, a paper support box 2, a housing (not shown), a paper support plate 3, a paper inlet 4, and a paper shredding component 5 , drive motor 6, paper pickup unit 7, paper platen 8, through hole 9, waste paper bucket (not shown) and shaving nail unit 10, wherein:

[0095] The machine cover 1 is pivotally connected to one end of the paper support box 2 for covering or opening the shredder;

[0096] The housing is arranged under the paper holder 2 and is fixedly connected with the paper holder 2. In this embodiment, the fixed connection can be by snap-fitting, riveting, screwing, etc.;

[0097] The paper support plate 3 is arranged on the inner upper end surface of the paper support box 2, and is used to carry the stacked paper placed by the user (the situation of a piece of paper is also applicable);

[0098] The paper inlet 4 is ope...

Embodiment 2

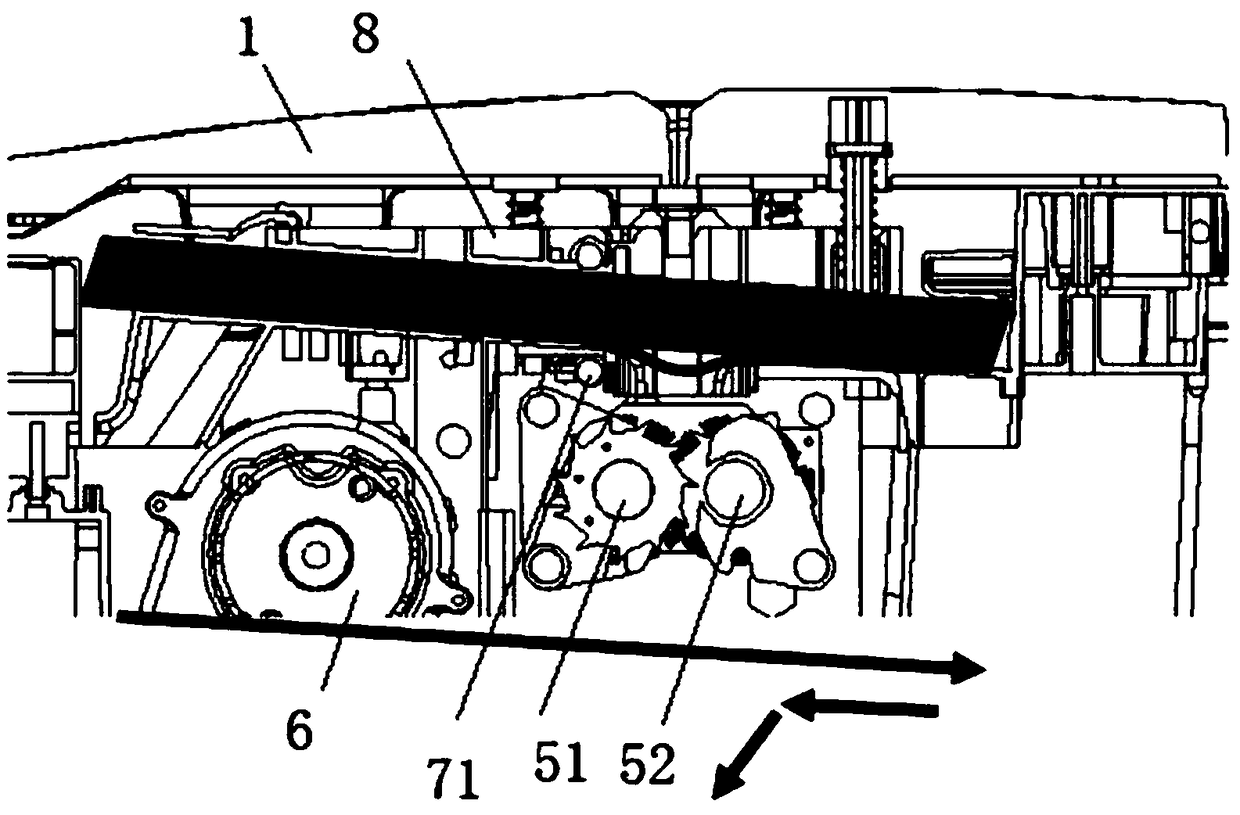

[0123] like image 3 As shown, the present invention additionally discloses a method for shaving nails with an automatic shredder, using the above-mentioned automatic shredder to perform shredding and shaving, specifically comprising the following steps:

[0124] Step 1: Open the cover of the paper shredder, and place a certain number of stacked papers bound with staples or paper clips at any of the four corners on the cardboard that is inclined relative to the horizontal plane;

[0125] Step 2: Closing the machine cover, the paper pressing plate arranged on the lower end of the machine cover and elastically connected with the machine cover through several elastic parts presses the laminated paper placed on the cardboard;

[0126] Step 3: Start the drive motor of the paper shredder, and drive the first cutter shaft and the second cutter shaft on the left and right sides below the paper inlet on the cardboard support to run, and at the same time, the drive is set in the first c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com