Galvanized steel pipe multi-angle inclination hole drilling device and galvanized steel pipe inclination hole drilling process

A galvanized steel pipe, multi-angle technology, applied in the direction of drilling/drilling equipment, boring/drilling, manufacturing tools, etc., can solve problems such as deviation of inclined holes, time-consuming and laborious, and inability to drill holes at multiple angles, and achieve Reduce labor intensity, improve work efficiency, and achieve the effect of precise drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

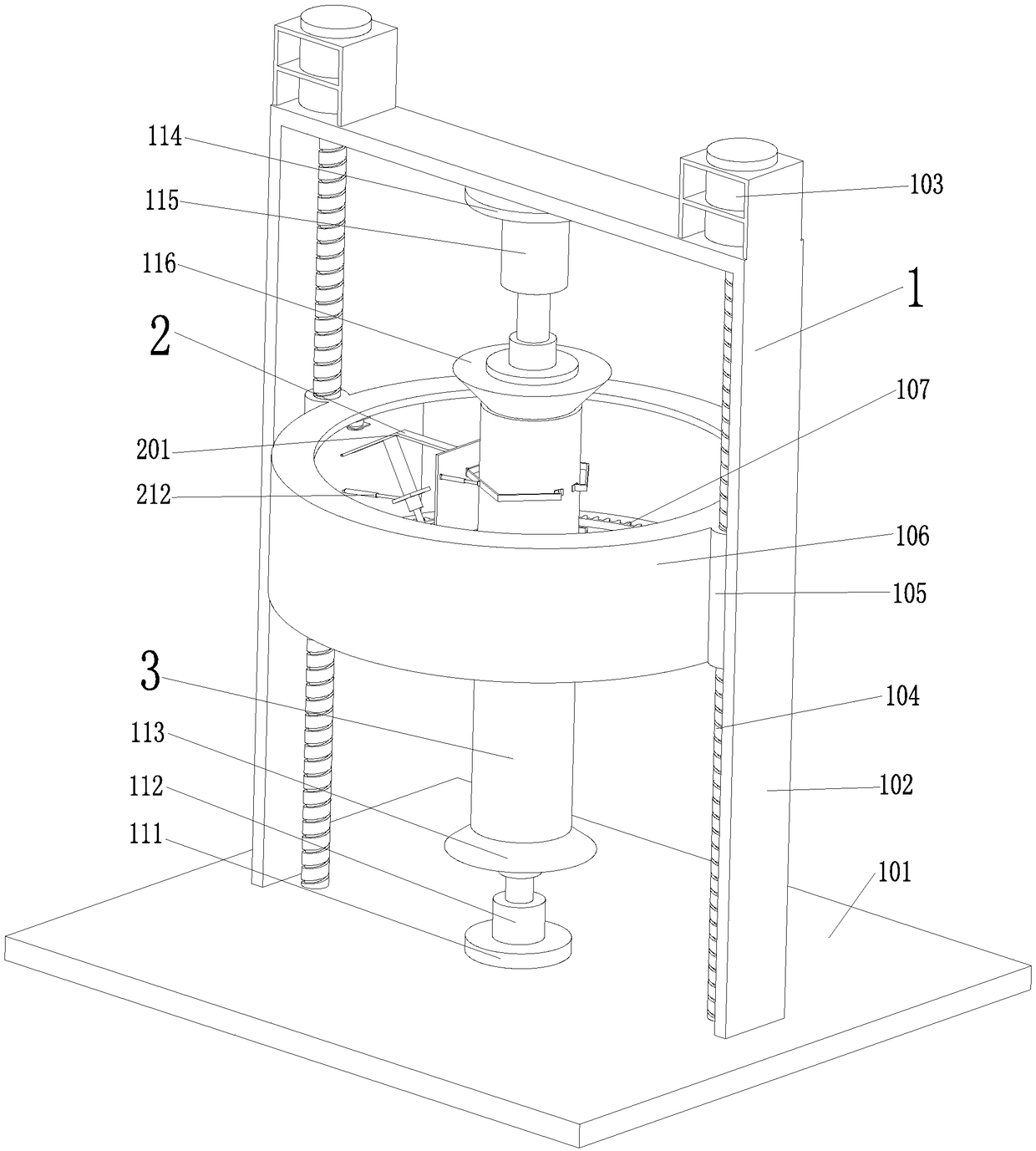

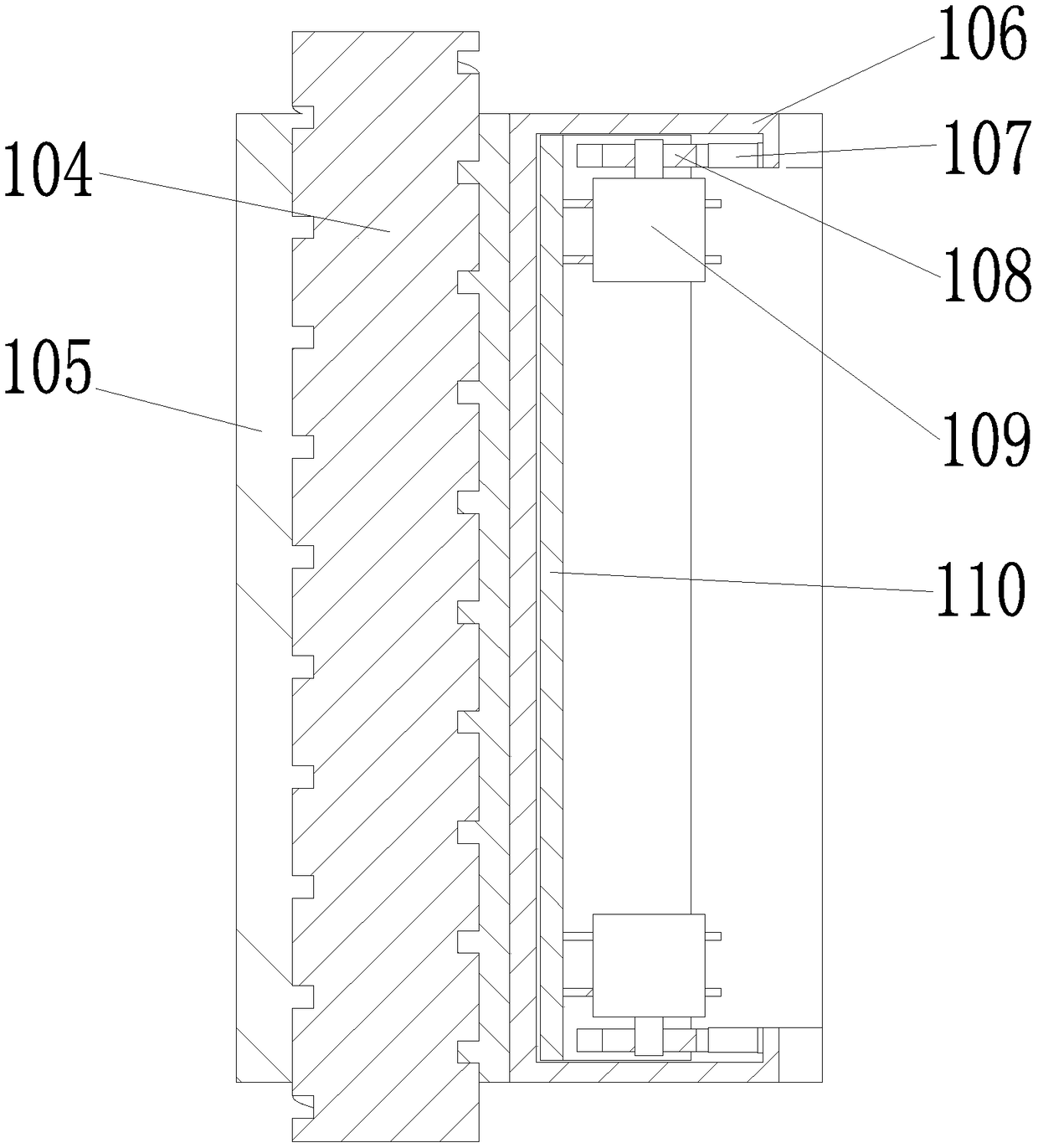

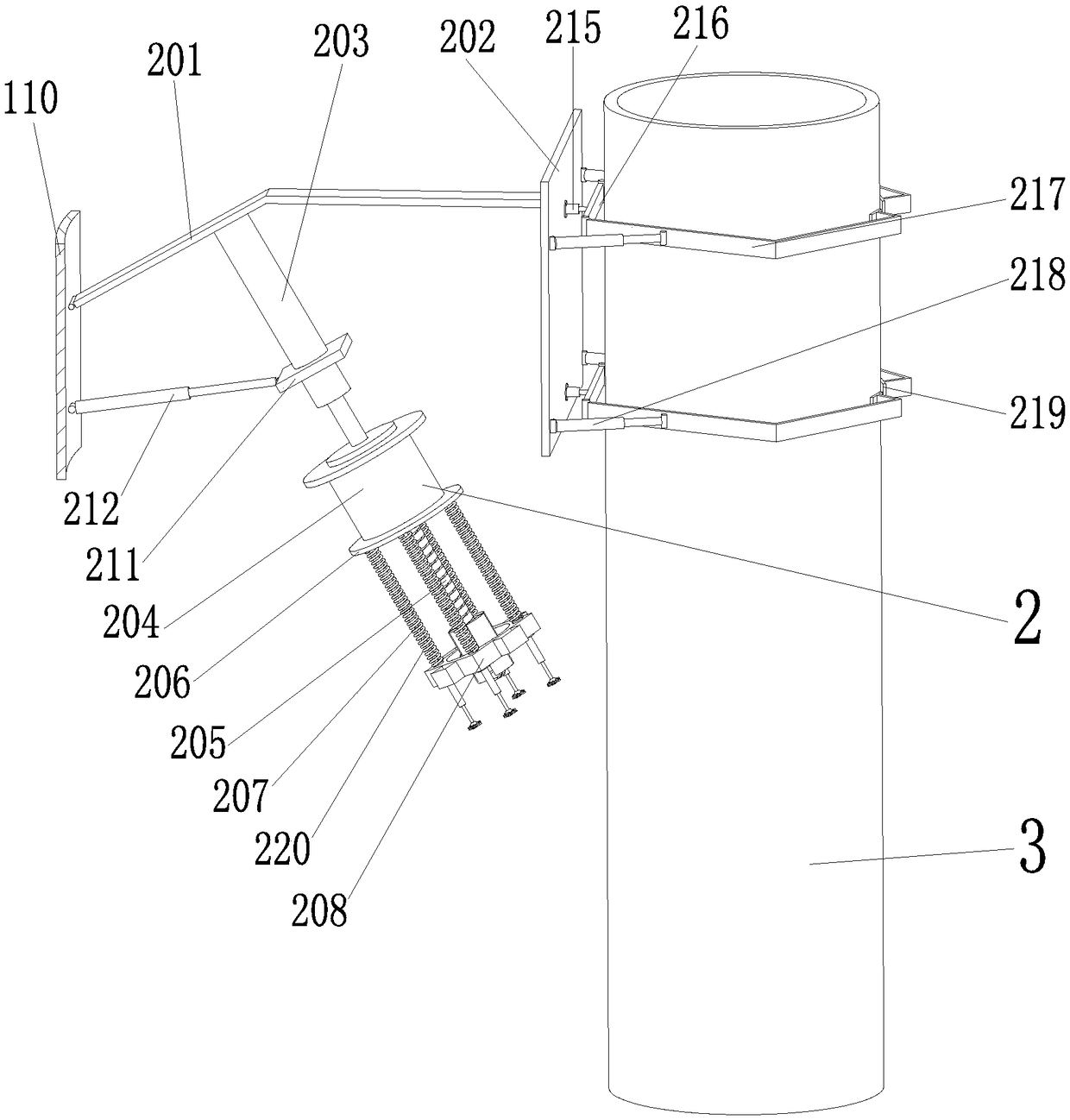

[0023] like Figure 1 to Figure 5 As shown, a multi-angle drilling device for galvanized steel pipes includes a support mechanism 1, an actuator 2, and a steel pipe body 3. The support mechanism 1 is equipped with an actuator 2, and the actuator 2 is located inside the support mechanism 1. The mechanism 2 leans against the outer wall of the steel pipe body 3, the steel pipe body 3 is located inside the support mechanism 1, the steel pipe body 3 has a hollow cylindrical structure, and the support mechanism 1 plays the role of tightening and moving up and down the steel pipe body 3, and the support mechanism 1 Drive the actuator 2 to move up and down and make a circumferential movement around the steel pipe body 3, the actuator 2 clamps against th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap