Production technology of engine bearing bush

A production process and engine technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the uneven coating on the surface of the workpiece to be plated, the inability to complete the clamping of different types of parts, and affect the sputtering quality of the workpiece to be plated, etc. problems, to achieve the effect of ensuring reliability, simple clamping process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

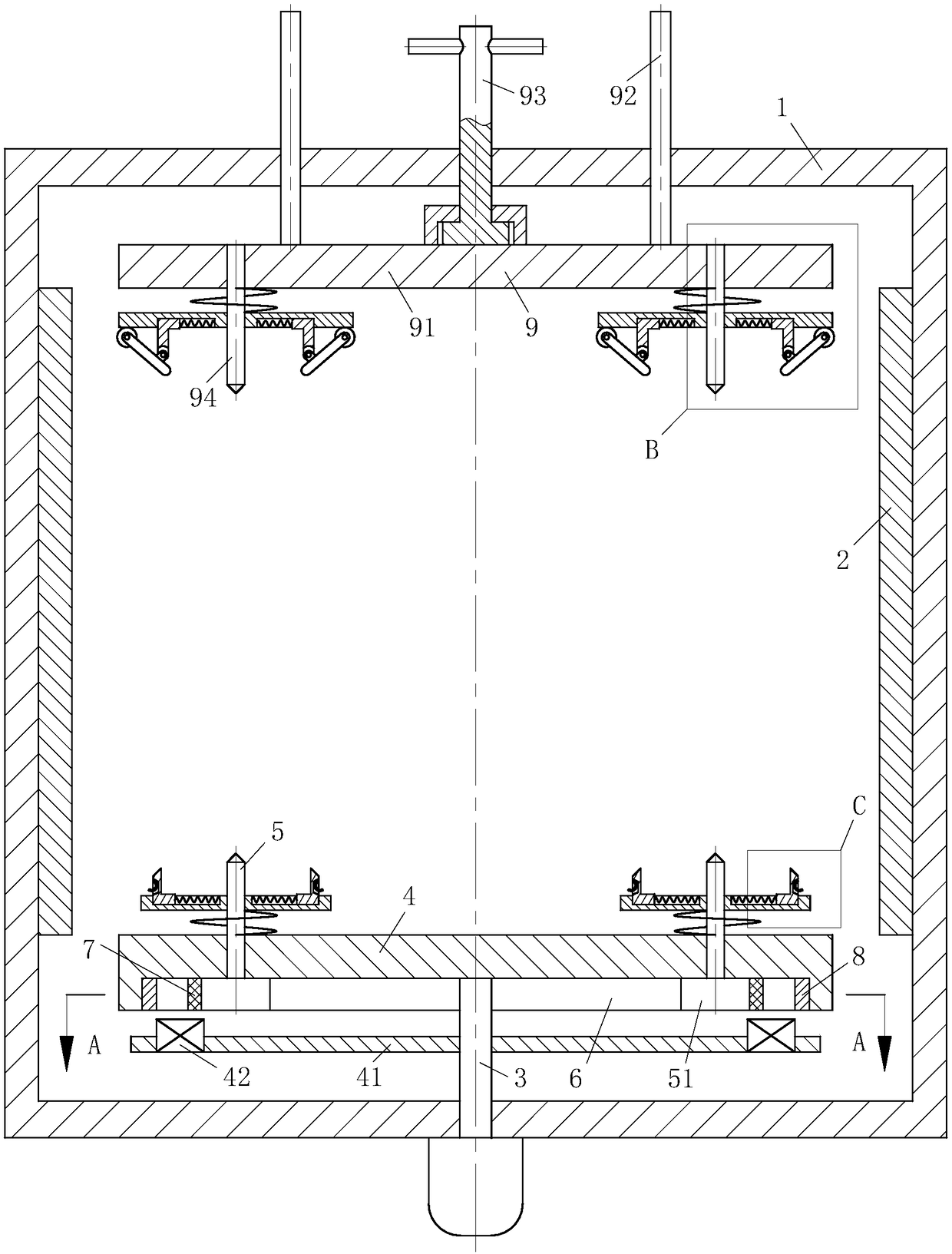

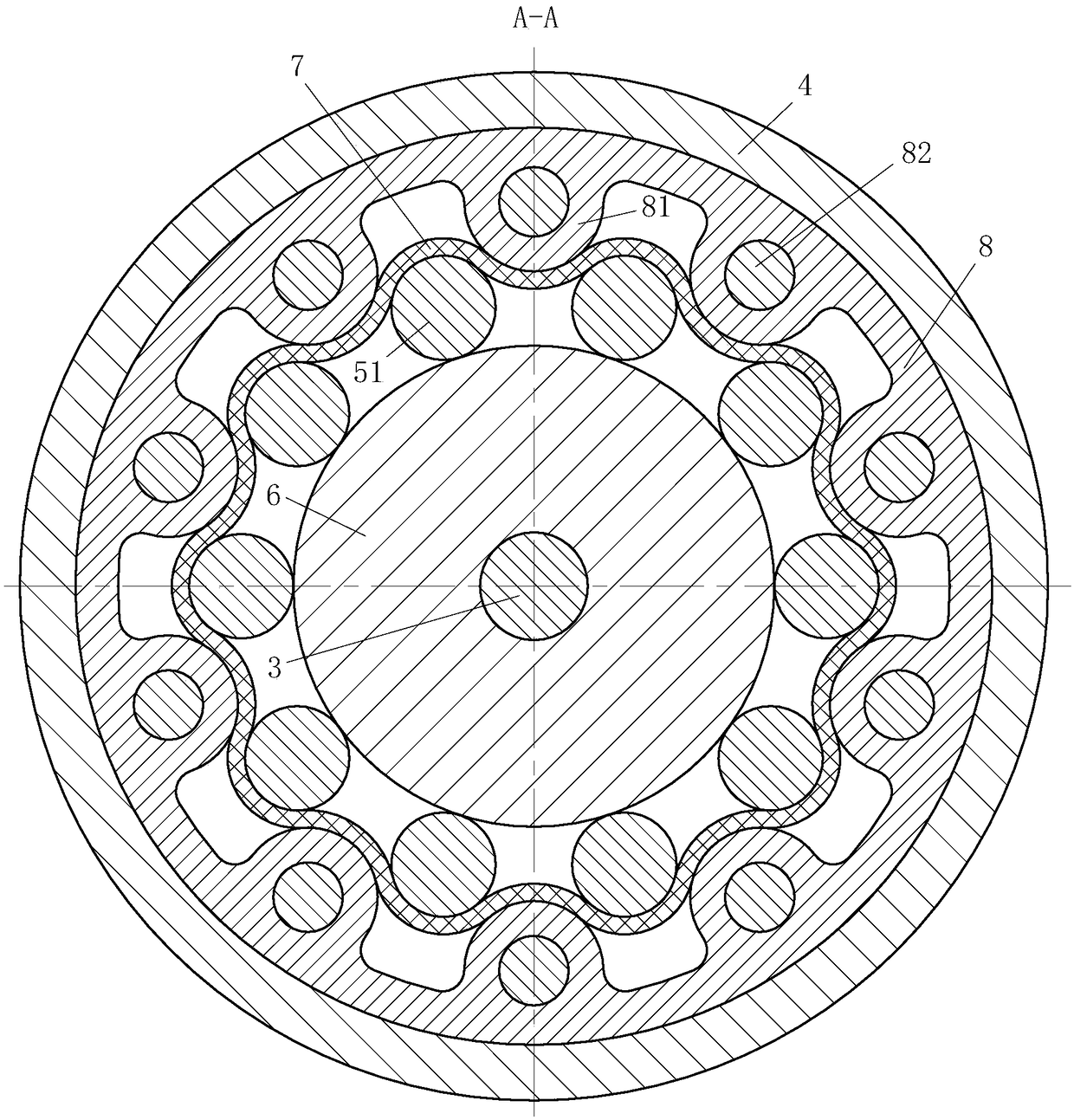

[0032] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

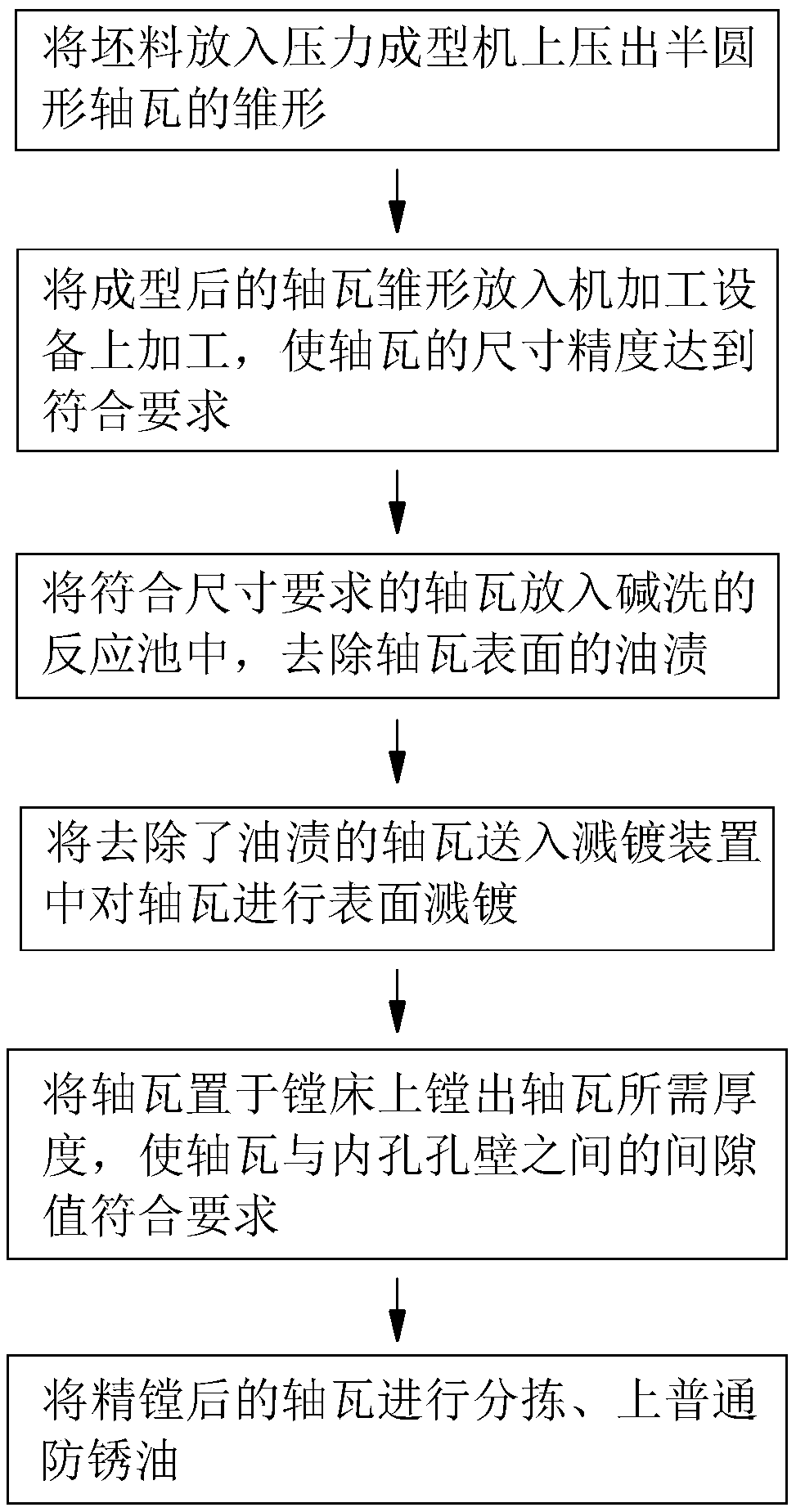

[0033] Such as Figure 1 to Figure 5 Shown, the production technology of a kind of engine bearing bush of the present invention, this method comprises the steps:

[0034] Step 1: Put the blank into the pressure forming machine and press out the prototype of the semicircular bearing bush;

[0035] Step 2: Put the prototype of the bearing pad formed in step 1 into the machining equipment for processing, so that the dimensional accuracy of the bearing pad meets the requirements;

[0036] Step 3: Put the bearing bush that meets the size requirements in step 2 into the reaction pool for alkali cleaning to remove the oil stain on the surface of the bearing bush;

[0037] Step 4: Send the bearing bush from which oil stains have been removed in step 3 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com