Pressurizing and impregnating device for corrosion protection of woods

A technology of wood preservation and pressure impregnation, applied in the field of materials, can solve problems such as pouring out, and achieve the effect of convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

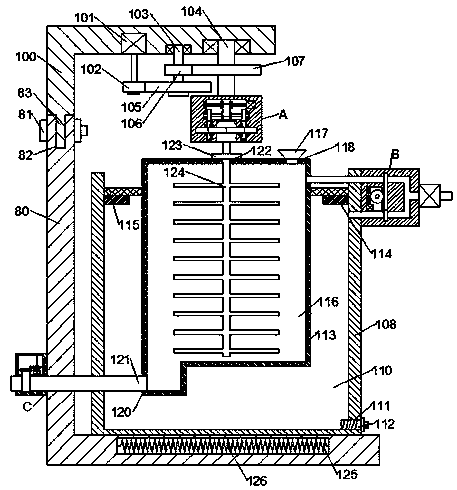

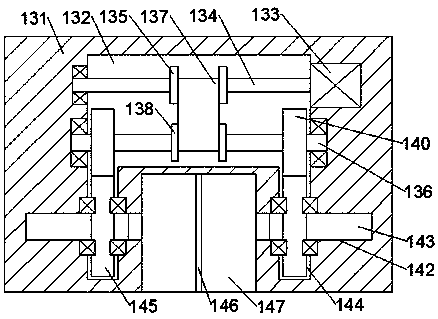

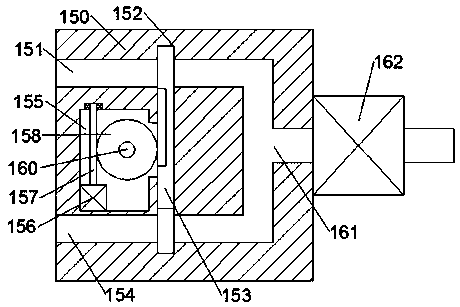

[0016] Combine below Figure 1-5 The present invention will be described in detail.

[0017] refer to Figure 1-5, according to an embodiment of the present invention, a kind of pressure impregnation for wood preservation, which includes a first L-shaped device frame 100, and the bottom end surface of the vertical part of the first L-shaped device frame 100 is provided with a plug strip 83. The bottom of the horizontal part of the first L-shaped device frame 100 is fixedly installed with a secondary deceleration mechanism, and the secondary deceleration mechanism includes a bottom end surface fixedly installed in the horizontal part of the first L-shaped device frame 100. The first motor 101, the first pinion 102 is fixedly installed on the downward output shaft of the first motor 101, and the bottom end surface of the horizontal part of the first L-shaped device frame body 100 is located on the right side of the first motor 101 The first rotating shaft 103 is fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com