Water adding system of powder mixer

A mixer and powder technology, used in clay mixing devices, liquid batching supply devices, clay preparation devices, etc., can solve the problems of product quality difference, easy to spray water column, easy to bend (different local moisture and so on)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0014] The claims are summarized from the examples, so they should contain all the contents of the claims, and be a little more specific than the claims, so that people can get the claims from the examples.

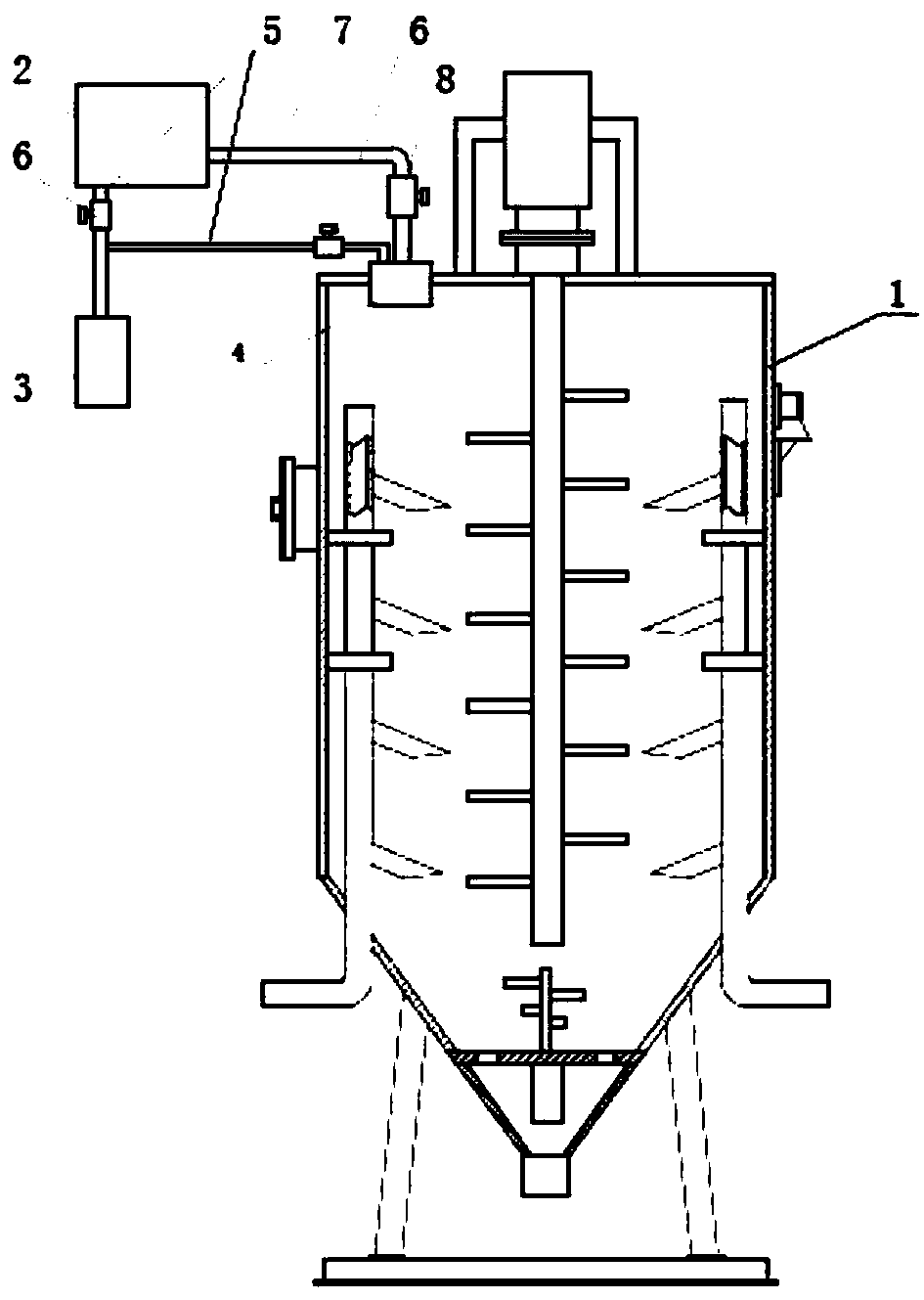

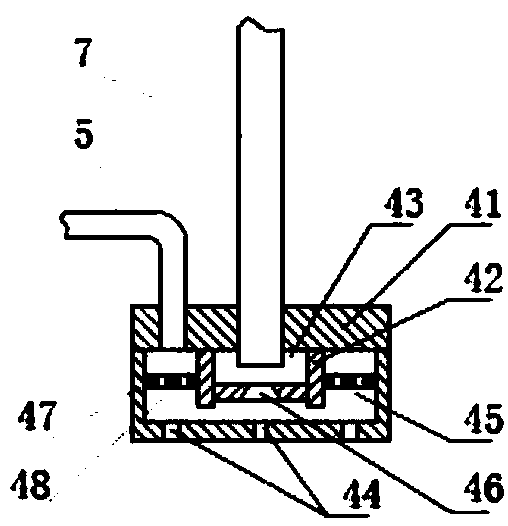

[0015] like figure 1 As shown, the powder material mixer water adding system provided by the present invention includes a powder material mixer 1, and the powder material mixer 1 in the figure is a structure of the powder material mixer. It is an existing technology, so it will not be repeated here. The water adding system of the present invention is not only applicable to the powder mixer with the structure in the figure, but also applicable to powder mixers with other structures. The water adding system of the powder mixer also includes a water adding tank 2 With the air compressor 3, the water supply tank 2 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com