Broken wire monitoring structure and monitoring method for photovoltaic silicon wafer cutting machine

A technology for cutting machines and silicon wafers, applied in photovoltaic power generation, stone processing equipment, electrical components, etc., to achieve the effect of easy intervention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

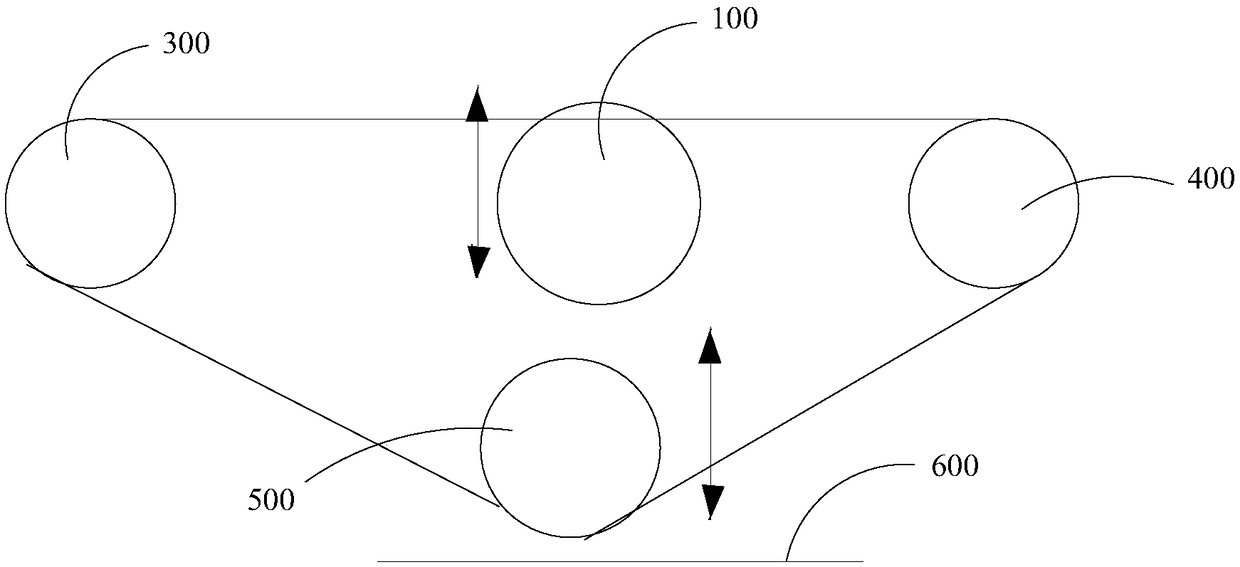

[0035] See figure 1 with figure 2 As shown, this embodiment provides a disconnection monitoring structure of a photovoltaic silicon wafer cutting machine, which is suitable for monitoring the disconnection status of a photovoltaic silicon wafer cutting machine in the diamond wire cutting mode, and includes a detection wire 600 and a monitoring module. The photovoltaic silicon wafer cutting machine is driven by a frequency converter to drive a three-phase AC asynchronous motor. The driving wheel 300 is driven by a coupling. The diamond wire 200 is cut through the guide wheel 400 and the automatic tensioning wheel 500 is under the action of a predetermined and adjustable tension. The silicon wafer 100 to be processed is cut at a high speed. When the cutting diamond wire 200 is broken, the tension wheel 500 loses its balance due to the force and drops.

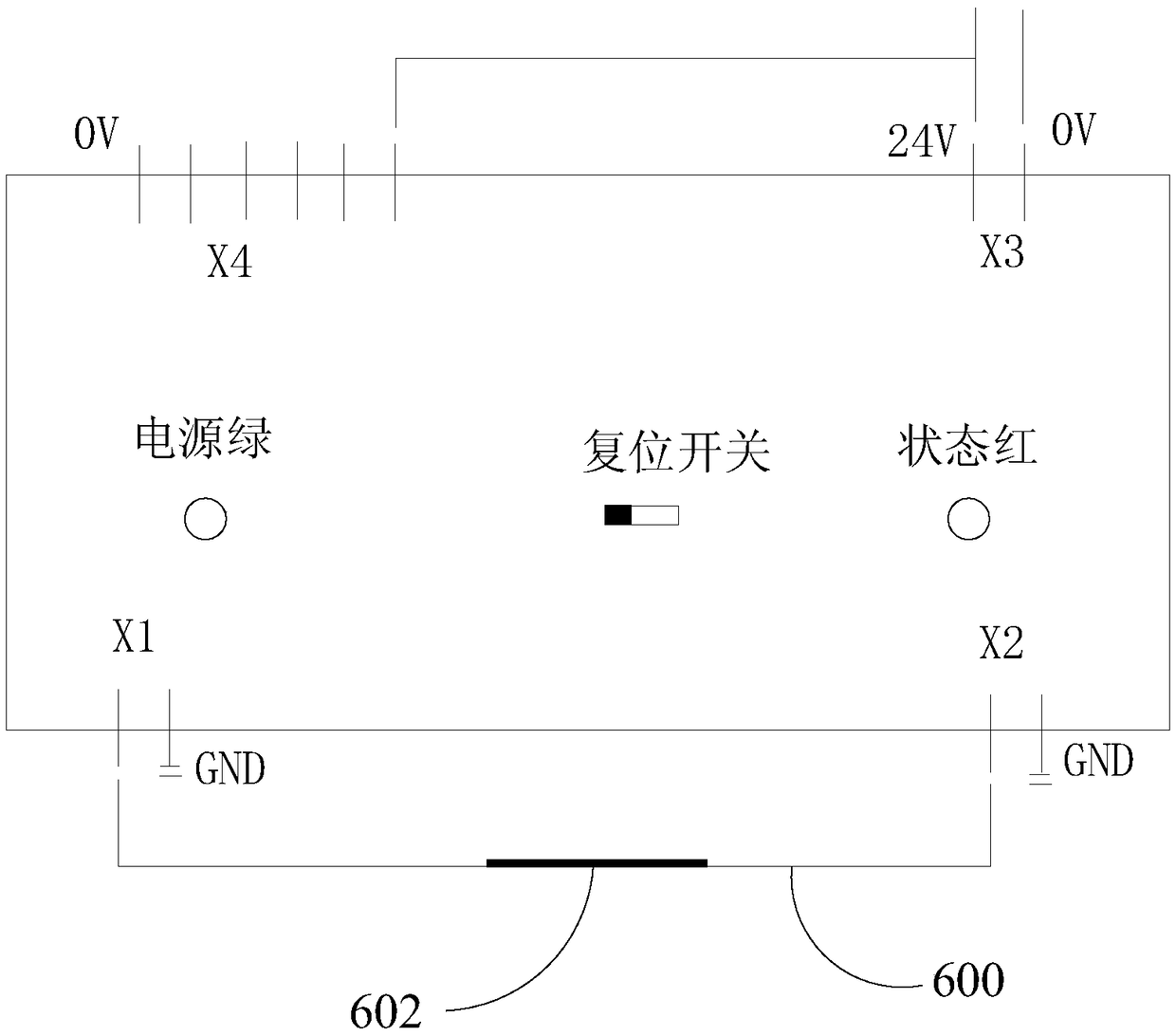

[0036] The detection wire 600 includes a section of bare wire 602; the bare wire 602 is located directly below the tension wheel 5...

Embodiment 2

[0048] This embodiment provides a method for monitoring wire breakage of a photovoltaic silicon wafer cutting machine, including:

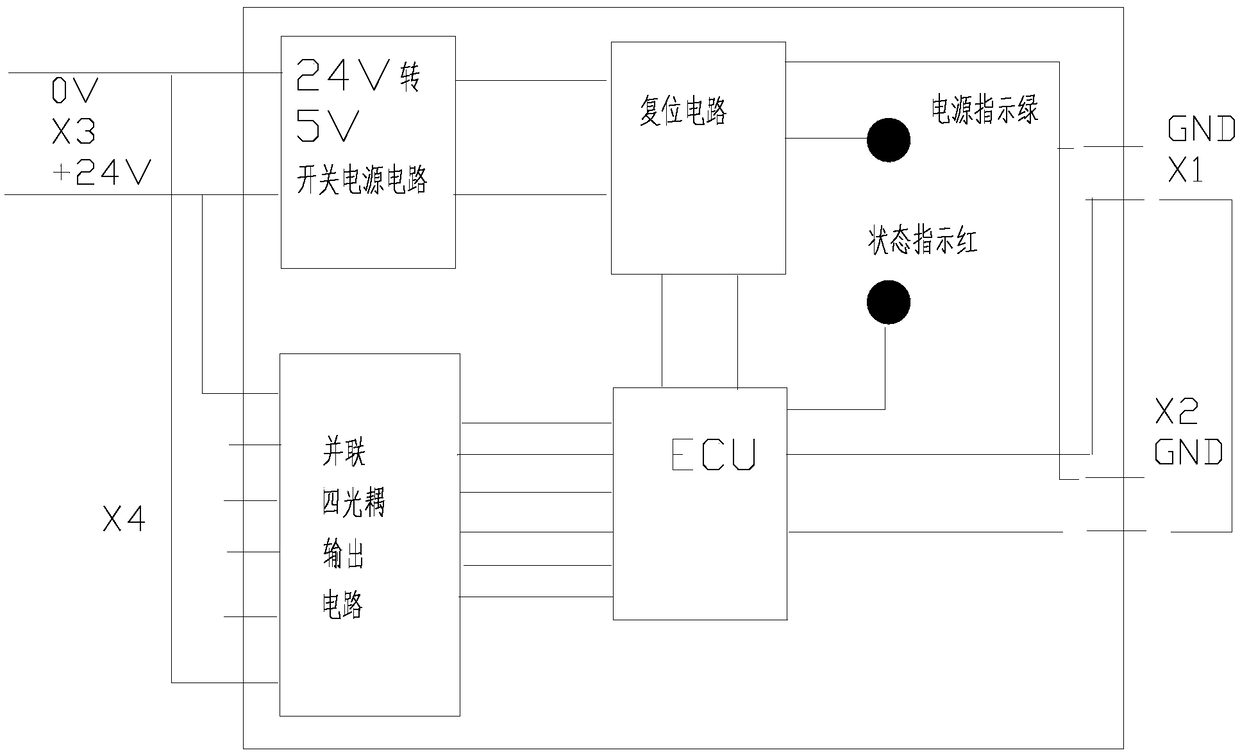

[0049] Step S1: The detection wire 600 is suitable for contacting the tension wheel 500 of the diamond wire cutting transmission mechanism of the photovoltaic silicon wafer cutting machine to ground the detection wire 600; wherein, the detection wire 600 is in a normally energized state.

[0050] Step S2: The micro-processing unit learns the connection state between the first detection terminal and the second detection terminal connected to the detection wire 600.

[0051] The micro-processing unit is connected with a control signal output unit and a status indicator; the control signal output unit is suitable for controlling the driving wheel frequency converter of the diamond wire cutting transmission mechanism to quickly stop and / or the alarm signal light of the photovoltaic silicon wafer cutting machine is on. Specifically, when the cutting diamond w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com