Bobbin classified discharging device

A technology of discharging device and yarn bar, which is applied to conveyor control device, loading/unloading, transportation and packaging, etc., can solve the problems of increased workload, production and processing workload, low efficiency, etc., to reduce labor costs, Improve the efficiency of sorting and recycling, and the effect of efficient sorting and sorting of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

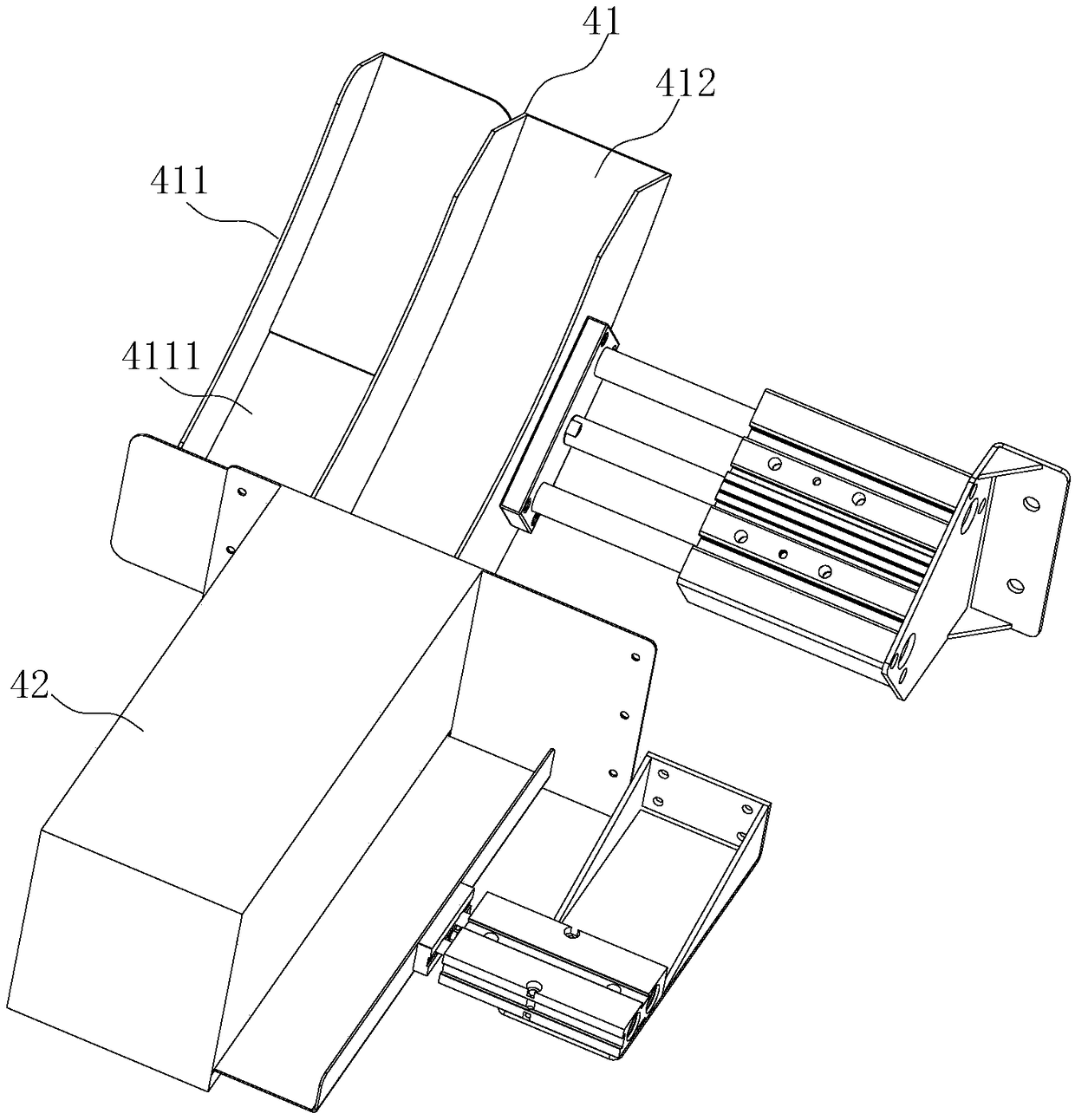

[0026] Such as figure 1 As shown, the present invention includes a discharge guide 41 and a driving mechanism for driving the movement of the discharge guide 41. The discharge guide 41 is provided with a first guide groove 411 and a second guide groove 412 arranged in parallel. The first guide groove The 411 is provided with a guide slot 4111.

[0027] When the driving mechanism of the present invention drives the discharge guide 41 to move, when the first guide groove 411 corresponds to the position of the discharge port of the external device, the material enters the first guide groove 411 from the discharge port and passes through the first The guide slot 4111 on the guide trough 411 is discharged. When the second guide trough 412 corresponds to the position of the discharge port of the external device, the material enters the second guide trough 412 from the discharge port and passes through the second guide The outlet end of the trough 412 is led out. The present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com