Hydraulic separation vertical transportation system and method for solid waste on construction site

A solid waste, hydraulic separation technology, applied in solid separation, chemical instruments and methods, wet separation, etc., can solve the problems of potential safety hazards and large impact of vertical garbage channel transportation equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

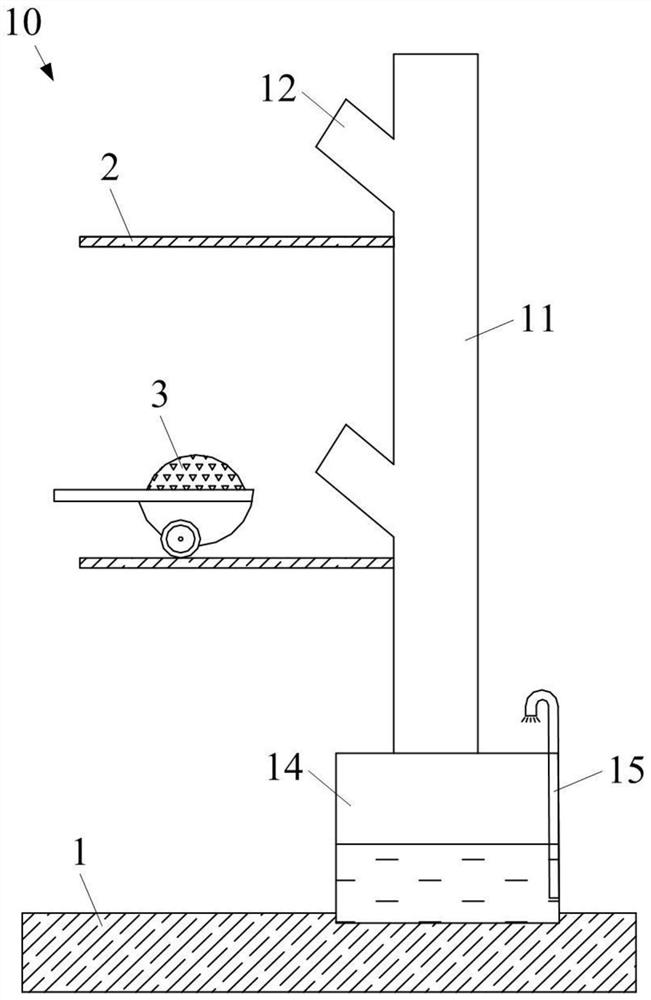

[0020] combine figure 1 The hydraulic sorting vertical transportation system 10 of the construction site solid waste of the present invention is illustrated, which includes:

[0021] The waste transportation pipeline 11 is vertically arranged and detachably connected to the outside of the main structure of the building. It is composed of multiple pipes connected end to end. Each floor 2 of the main structure of the building corresponds to at least one pipe. And the side wall of the waste transportation pipeline 11 corresponding to each floor 2 is provided with a waste delivery port 12 communicating with it;

[0022] The hydraulic separation device 14 is arranged at the bottom of the waste transportation pipeline 11, and the waste transportation pipeline 11 communicates with the hydraulic separation device 14;

[0023] A conveying device (not shown in the figure), which is arranged at the bottom of the water body in the hydraulic separation device 14, is used to transport heav...

Embodiment 2

[0031] combine figure 1 Illustrate the hydraulic sorting vertical transportation method of construction site solid waste 3 of the present invention, concrete steps are as follows:

[0032] The hydraulic sorting vertical transportation system 10 for solid waste at the construction site as described in Embodiment 1 is installed on the outside of the main structure of the building, and the solid waste 3 crushed on each floor 2 is thrown into the waste transportation pipeline 11 through the waste delivery port 12 After the solid waste 3 is transported vertically downward along the waste transportation pipeline 11 to the hydraulic separation device 14 under the action of gravity, the heavy impurities in the solid waste 3 sink into the conveying device at the bottom of the hydraulic separation device 14, and It is transported to one side by the conveying device, and drained together during the conveying process. The light impurities in the solid waste 3 float on the water surface, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com