Isometric sorting and conveying device

A conveying device, isometric technology used in the direction of shipping and packaging, conveyor objects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following specific embodiments will be further described in conjunction with the above-mentioned drawings.

[0034] In the following, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. It will be apparent, however, to one skilled in the art that the described embodiments may be practiced without some or all of these specific details. In other instances, well known processing steps have not been described in detail.

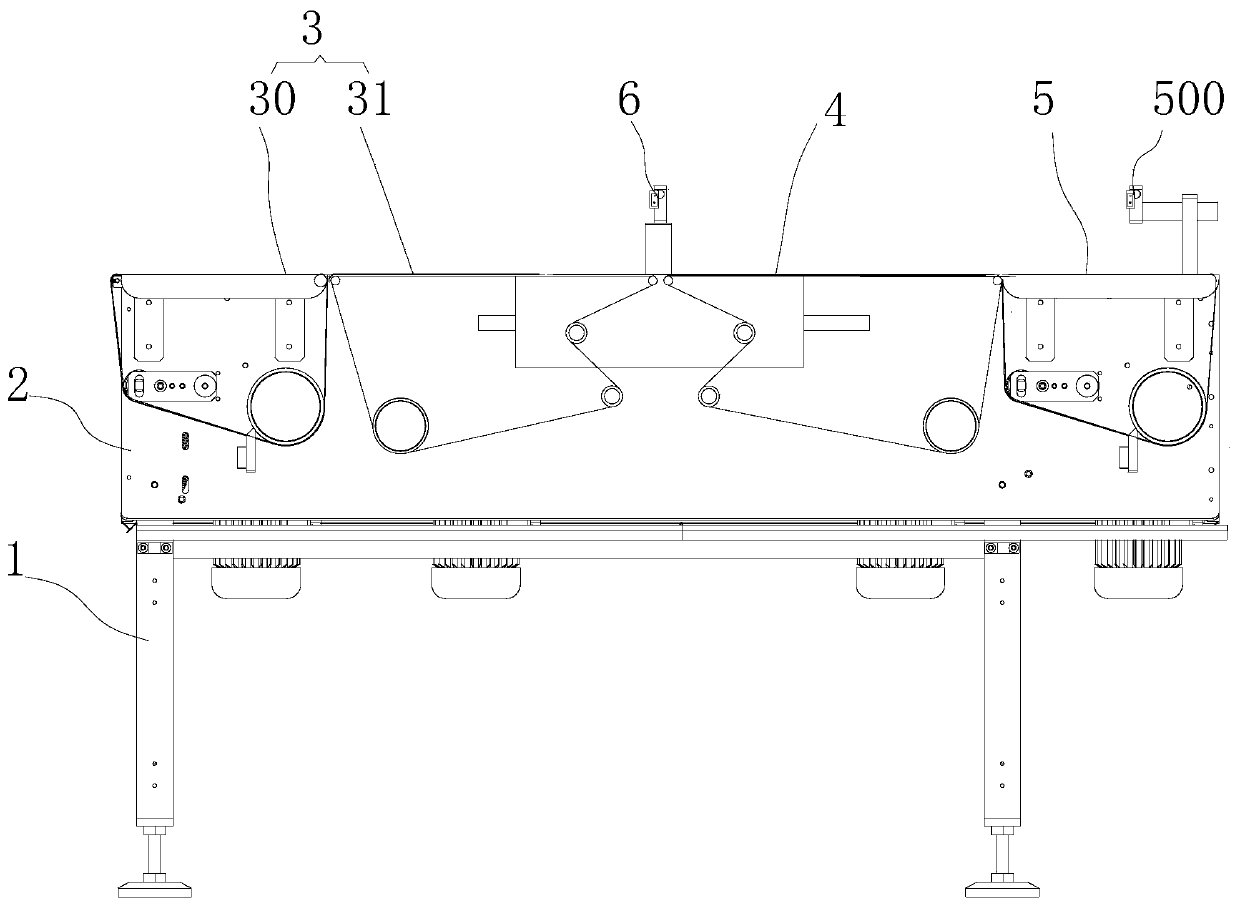

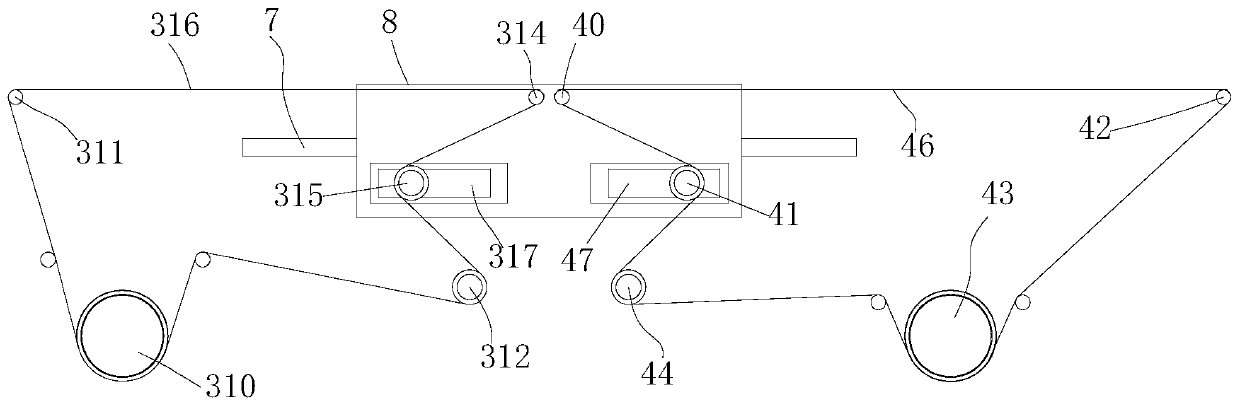

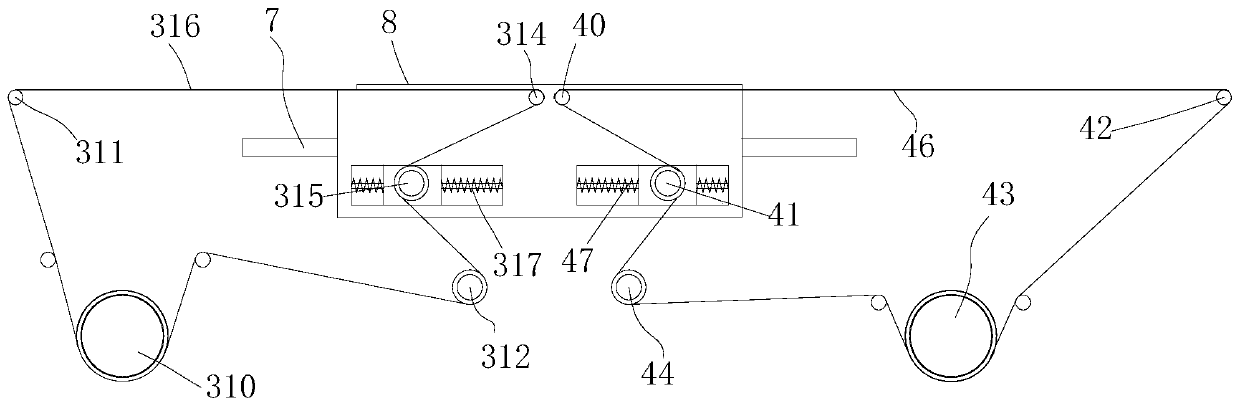

[0035] Such as figure 1 , Figure 14 and Figure 15 As shown, the equidistant material conveying device includes a support frame 1 and two installation plates 2 arranged on the support frame 1 in parallel. A fast conveying mechanism 3 , a stacking conveying mechanism 4 and an equidistant conveying mechanism 5 are sequentially arranged between the two mounting plates 2 . The fast conveying mechanism 3 quickly conveys the materials to the stacking conveying mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com