Screen-spraying wall surface trowelling device based on building construction

A technology for building construction and net spraying, which is applied in construction, building structure, shaft equipment, etc., can solve the problems of low efficiency of manual troweling and no tools, and achieve the effects of tight sealing, good work efficiency and convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

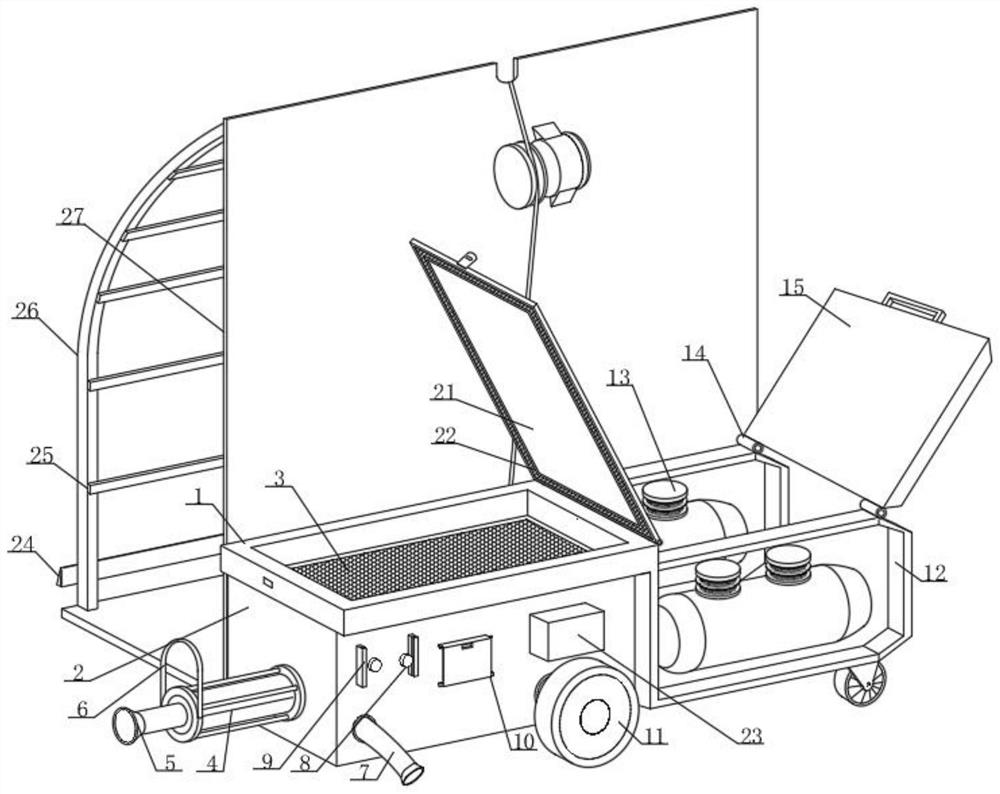

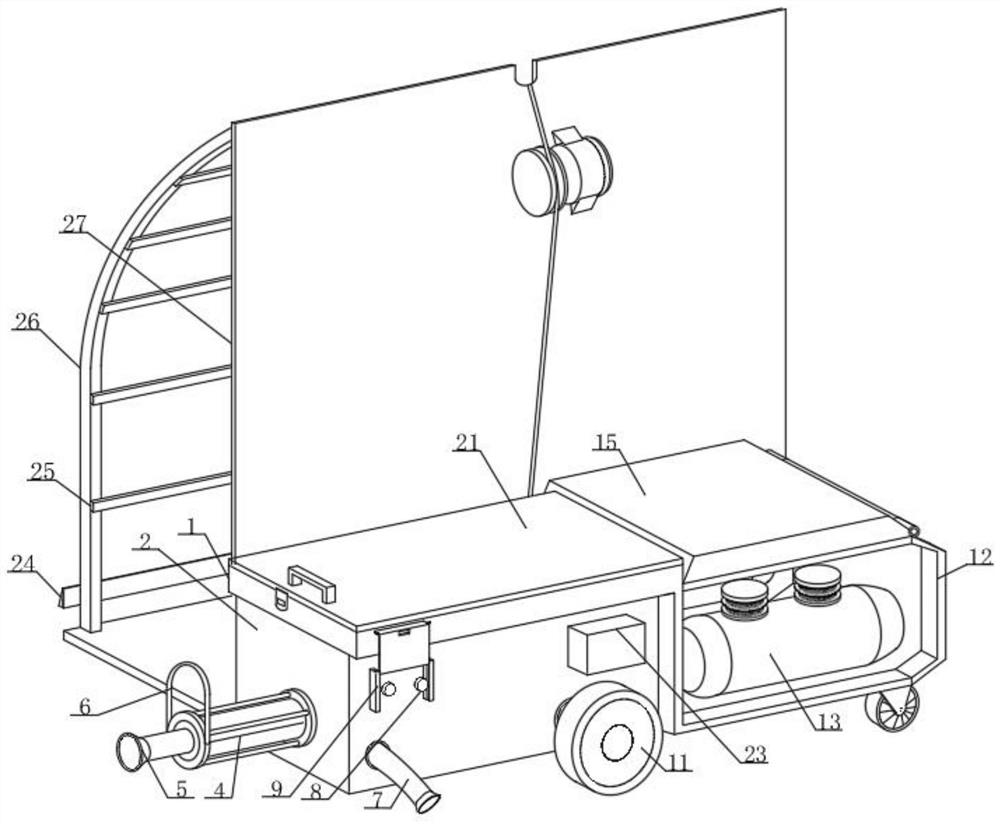

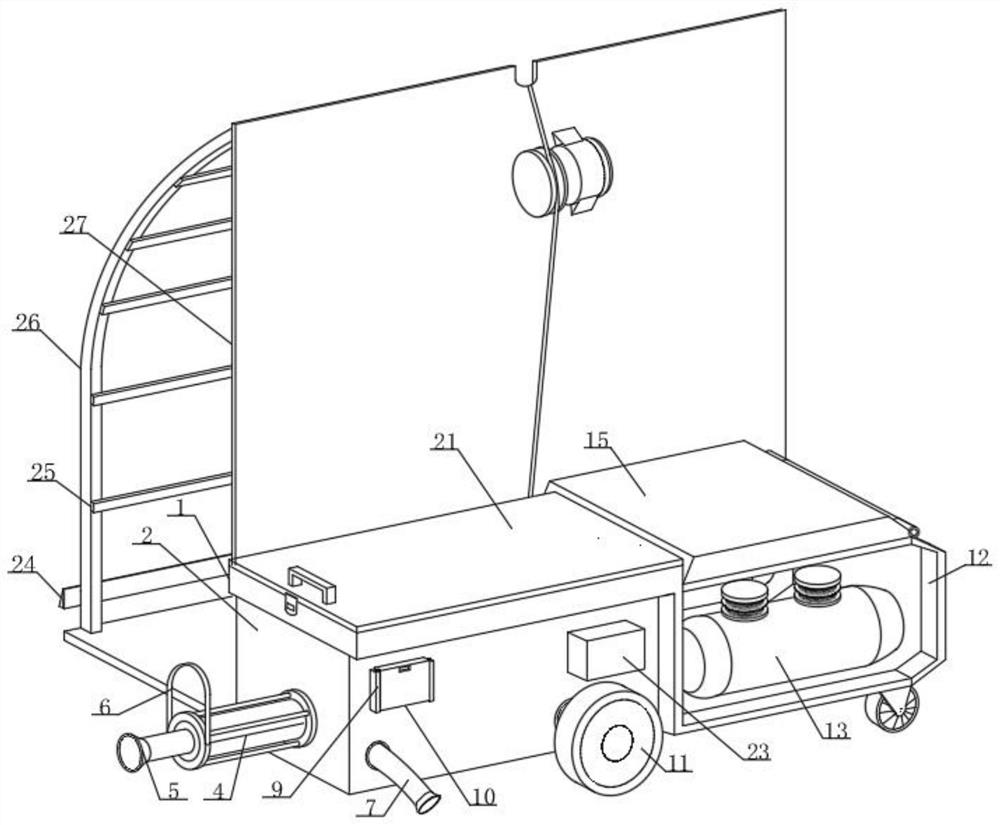

[0032] See figure 1 , 2 3, 4, 5, 6, 6, and the present invention provides a technical solution: a construction-based construction mesh spray wall spraying device, including the injection port 1 and the bin bin 2, the bottom end of the injection port 1 The surface of the pressing position 2 is provided, and the surface of the pressurized position 2 is provided with the filter 3, and the upper left side of the pressurized bin 2 is provided with the discharge tube 4. The surface of the discharge tube 4 is provided with a traction hook 6, and the discharge tube 4 The top end is provided with a discharge port 5, and the front end of the pressurized bin 2 is provided with a cleaning tube 7, and a power switch 8 is provided above the cleaning tube 7. On one side of the power switch 8, a finite block 9 is provided, and the surface setting of the limit block 9 is set. There is a dust cover 10, and a moving wheel 11 is provided on one side of the cleaning tube 7, and the right side of the p...

Embodiment 2

[0035] See figure 1 , 2 3, 4, 5, 6, 7, one based on the construction of the construction mesh spraying device, the limit block 9 is disposed, and the two limit blocks 9 are respectively disposed on both sides of the power switch 8, respectively. The moving wheel 11 is provided with two, and the two moving wheels 11 are mounted on both sides of the pressurized bin 2 through the fixed shaft, and the mobile wheel 11 can effectively improve the motor capacity of the equipment, and convenient for transport on the construction site. Work, improved single equipment, reduce the surface of the discharge tube 4 with four reinforcing rods, effectively improve the structural strength of the discharge tube 4 through the four strong rods, and ensure that the discharge tube 4 is high pressure for a long time The lower performance of the state remains stable, enhances the life of the discharge tube, and the four reinforcing rods are surrounded by the surface of the discharge tube 4, and two exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com