Preparation method for three-dimensional porous composite material

A composite material, three-dimensional porous technology, applied in the direction of chemical instruments and methods, electrolytic coatings, carbon compounds, etc., can solve the problems of low conductivity, large internal resistance, poor strength, etc., to increase the specific surface area, eliminate contact resistance, The effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

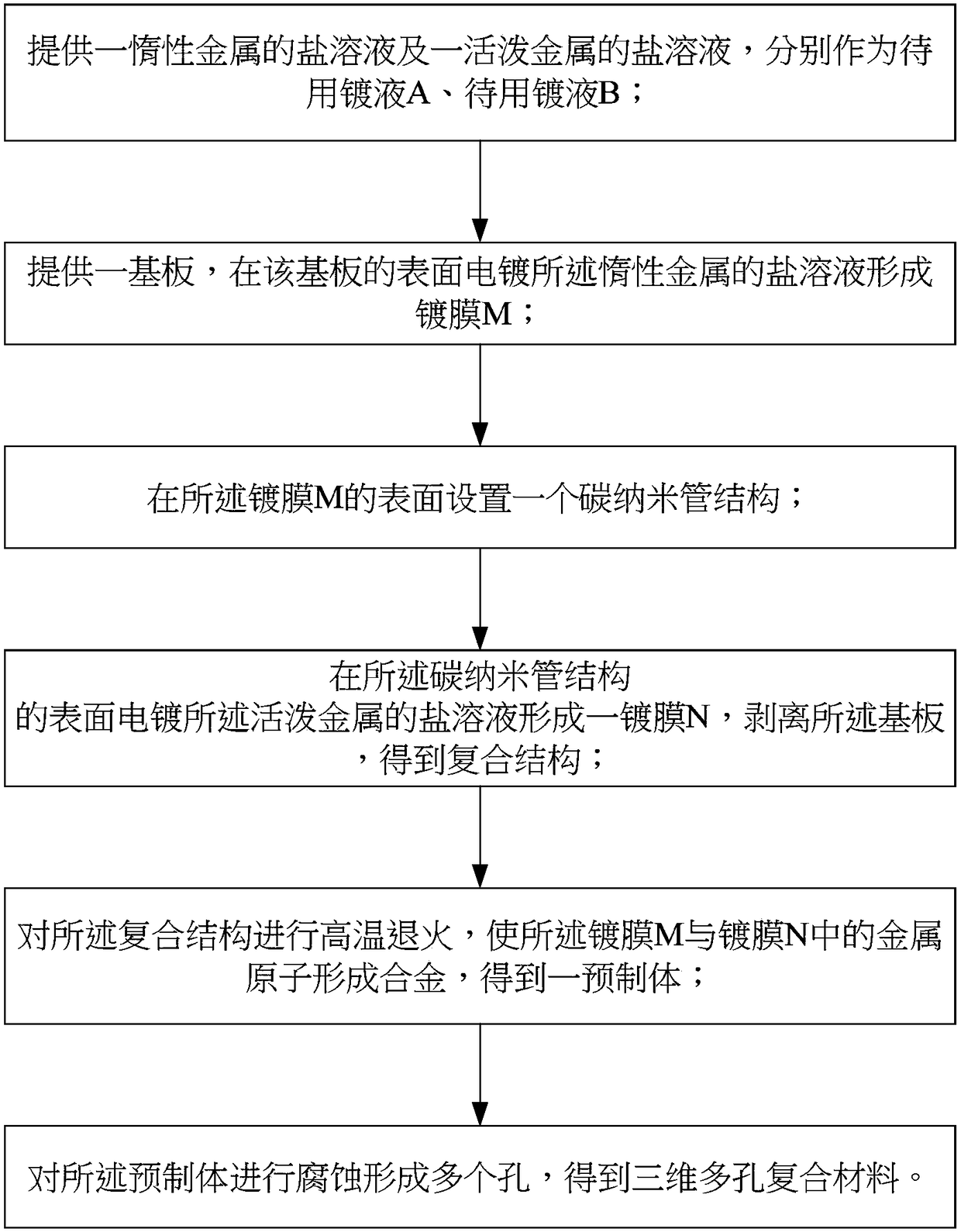

[0029] see image 3 , the present invention further provides a method for preparing the above-mentioned three-dimensional porous composite material, which mainly includes the following steps:

[0030] Step S10, providing a salt solution of an inert metal and a salt solution of an active metal;

[0031] The salt solution of the inert metal is used as the plating solution A for use, and the salt solution of the active metal is the plating solution B for use. The active metal can be any one of potassium, calcium, sodium, magnesium, aluminum, zinc, iron, tin and nickel. The inert metal can be any one of copper, mercury, silver, platinum and gold. Compared with the inert metal, the active metal is more likely to react with acid and alkali. Preferably, the salt solution of the inert metal is fully stirred with the glucose, so as to refine the subsequently formed inert metal coating. In this embodiment, the salt solution of the active metal is ZnSO 4 Solution, the salt solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com