Yarn feeding device for elastic yarn for flat knitting machine

An elastic yarn and yarn feeding technology, which is applied to flat knitting machines with individual moving needles, textiles and papermaking, weft knitting, etc., can solve the problems of elastic yarn supply, yarn characteristic change, supply, etc., and achieve stable tension value Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

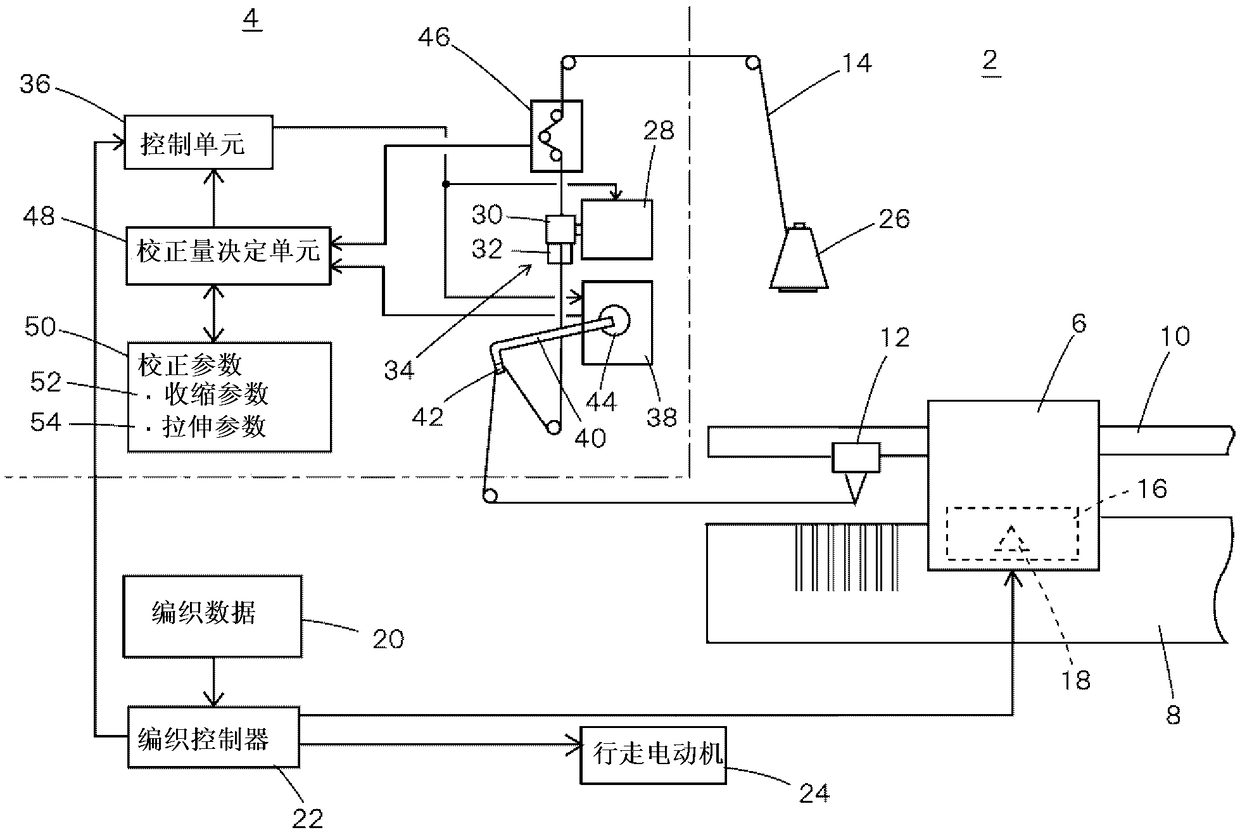

[0064] figure 1 The yarn feeding device of the elastic yarn in the flat knitting machine of the embodiment is shown. The embodiment in which the yarn is fed from the left side of the flat knitting machine is shown, but it is also possible to feed the yarn from the top or the right side. Among the figure, 2 is a flat knitting machine body, and 4 is a yarn feeding device. In the embodiment, the yarn feeding device 4 and the flat knitting machine 2 are integrated, but the yarn feeding device 4 may be independent from the flat knitting machine body 2 . Hereinafter, the flat knitting machine main body 2 is simply referred to as the flat knitting machine 2 . The flat knitting machine 2 is equipped with a carriage 6 and, for example, a pair of needle beds 8 at the front and rear, and the yarn guide 12, which is a yarn feeding member movable along the guide rail 10, is linked by the carriage 6, for example. The knitting needles of the needle bed 8 feed the elastic yarn 14 .

[006...

Embodiment 2

[0090] In this embodiment, a case where both the torque control of the buffer arm 40 and the control of the delivery mechanism 34 are performed when there is a difference in magnitude between the entry tension and the knitting tension will be described.

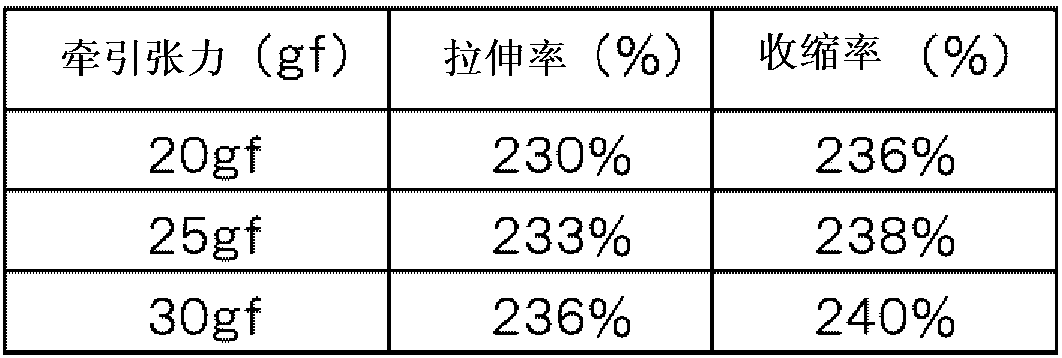

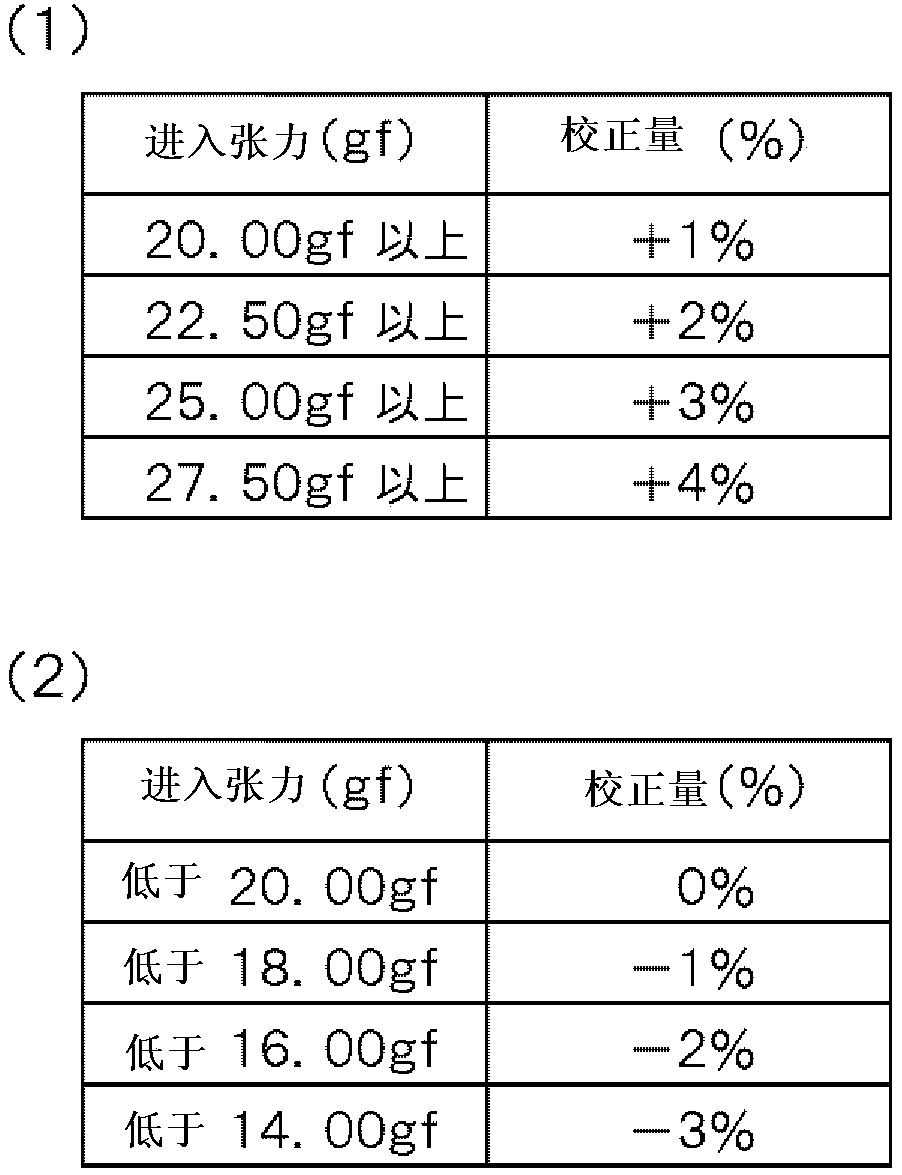

[0091]First, the correction amount determination unit 48 compares the entering tension of the elastic yarn 14 measured by the tension sensor 46 with the knitting tension generated by the buffer arm 40, and obtains a correction amount for the torque control of the buffer arm 40 in order to reduce the difference. . According to the correction amount, the control unit 36 controls the torque generator 38 to control the torque of the damper arm 40 . However, if the torque of the buffer arm 40 is greatly changed, the knitting tension will vary for each course, so it is not preferable to greatly change the torque of the buffer arm 40 . Therefore, not only the torque control of the buffer arm 40 is performed, but also the correcti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com