Roughing-up machine multi-shaft drive tension control system and method for controlling tension thereof

A technology of control system and tension control, applied in the direction of control/adjustment system, mechanical pressure/force control, non-electric variable control, etc., can solve the problems of uncontrollable tension, unstable tension control, and poor adjustment linearity in the start-stop phase, etc. problem, to achieve the effect of adding functions such as speed change of the sanding roller, simple debugging, and simple and practical hardware design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

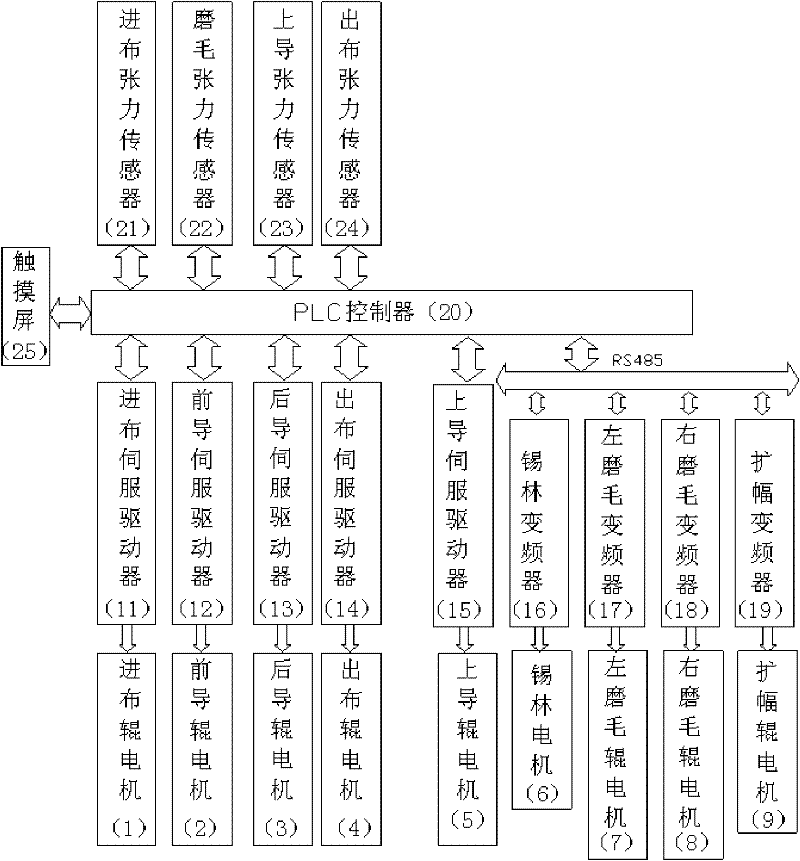

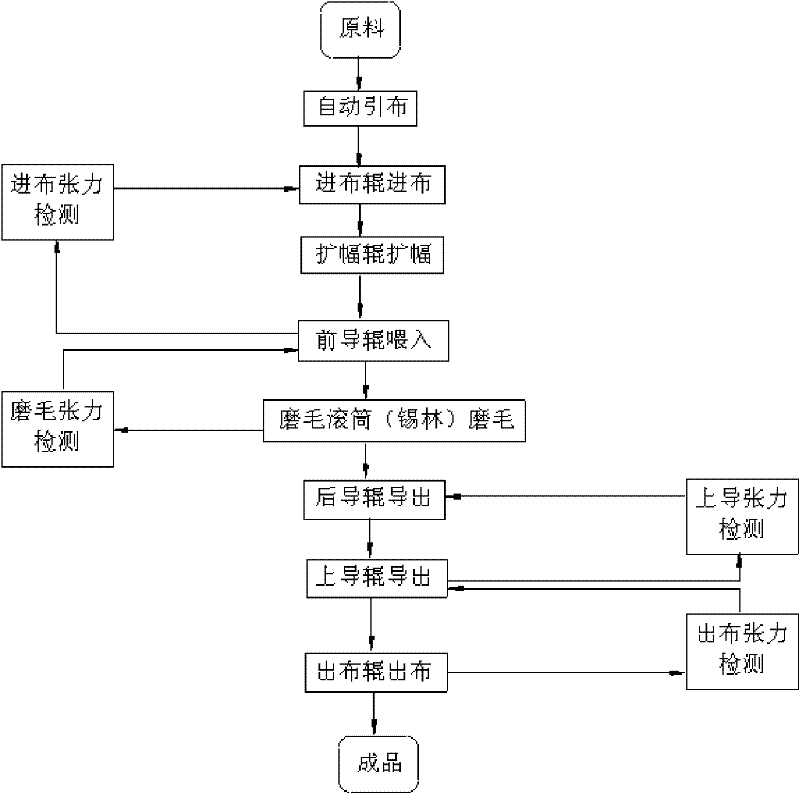

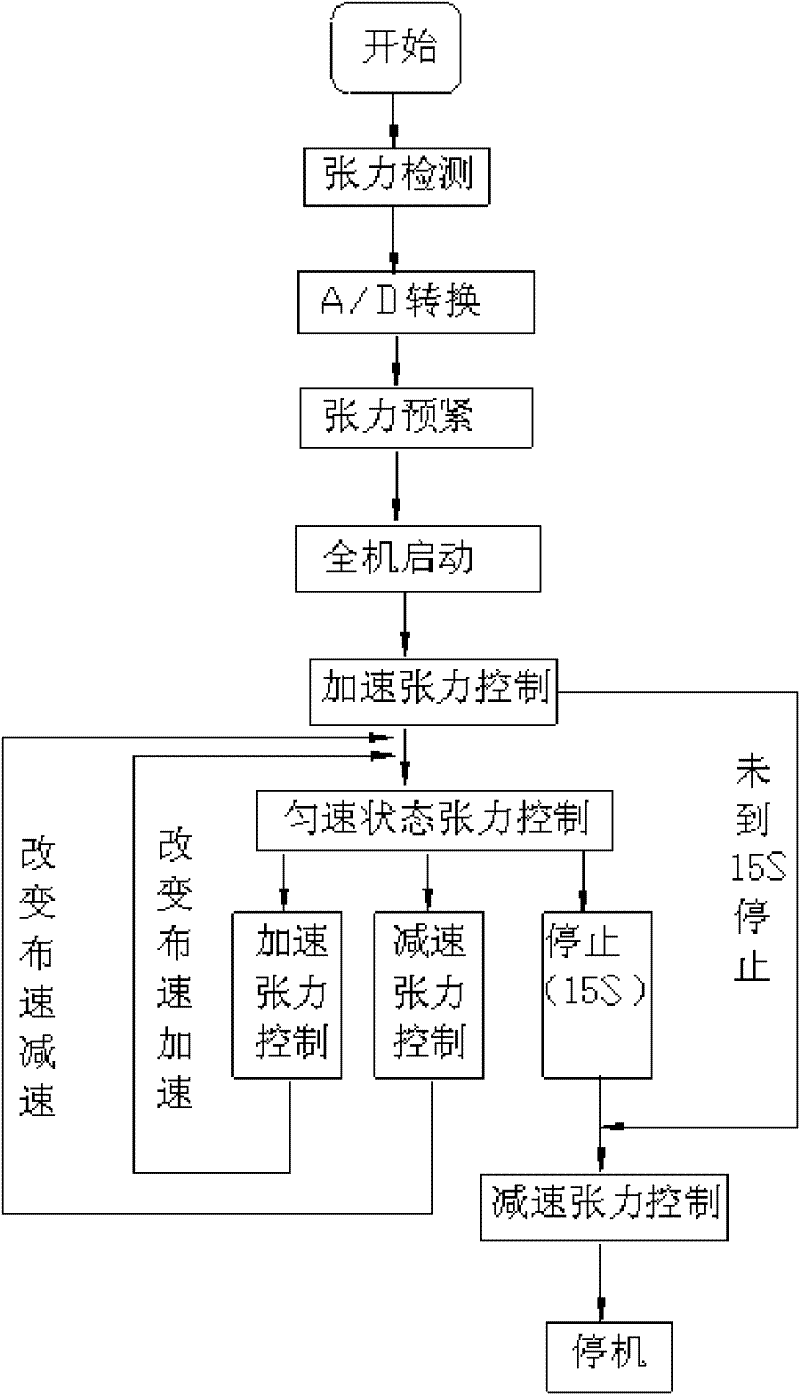

[0021] Embodiment 1: The multi-axis transmission tension control system of the sanding machine of this embodiment, such as figure 1 , Figure 4 As shown, it includes cloth guide control system and sanding control system based on constant tension control. The cloth guide control system based on constant tension control includes a cloth feed tension sensor 21 installed between the cloth feed roller 26 and the front guide roller 27 of the sanding machine, and a sanding tension sensor installed between the front guide roller 27 and the rear guide roller 28 22. The upper guide tension sensor 23 installed between the rear guide roller 28 and the upper guide roller 30, the cloth outlet tension sensor 24 installed between the upper guide roller 30 and the cloth outlet roller 29, and the PLC control connected to the above tension sensor device 20. The PLC controller 20 is connected with the cloth feeding servo driver 11, the leading servo driver 12, the rear guiding servo driver 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com