Stranded wire manufacturing method and manufacturing device thereof

A manufacturing method and technology of stranded wire, which are applied to auxiliary devices for rope making, textiles and papermaking, manipulation parts, etc., can solve problems such as inability to perform stable wireless communication, reflection of wireless signals, abnormal communication, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, examples of embodiments of the twisted wire manufacturing apparatus and the twisted wire manufacturing method using the manufacturing apparatus according to the present invention will be described with reference to the drawings.

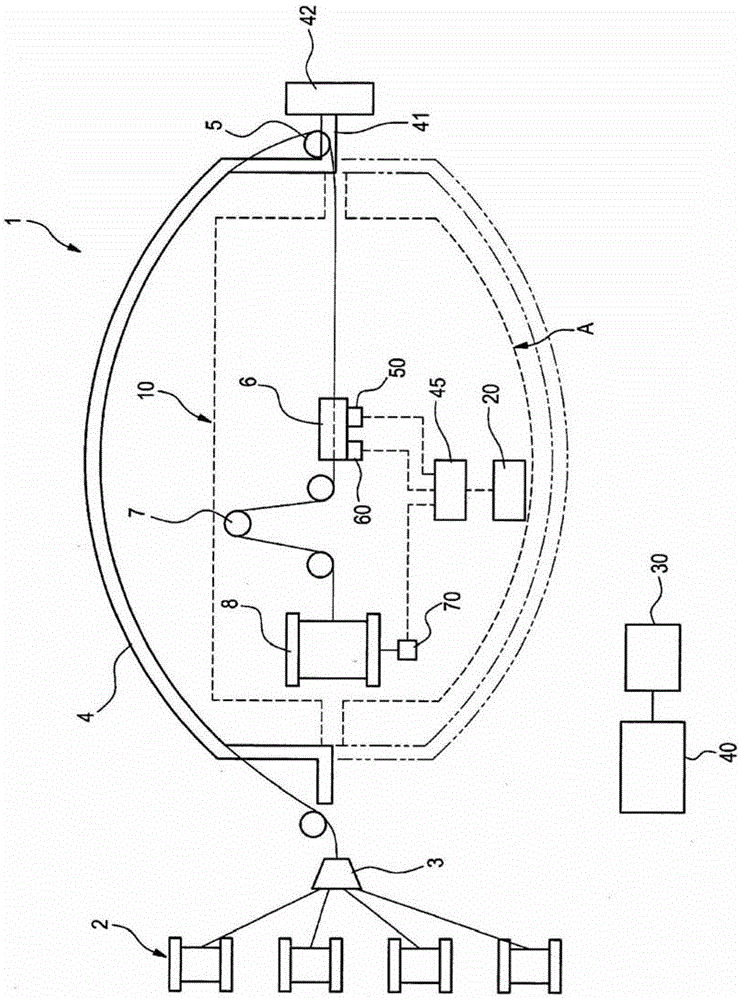

[0033] exist figure 1 The outline of the manufacturing apparatus 1 according to the embodiment of the present invention is shown.

[0034] The manufacturing apparatus 1 twists the strands wound on a plurality of extraction bobbins 2 to form a twisted wire, and winds up the twisted wire by a winding unit 8 . Such as figure 1 As shown, the manufacturing device 1 has: a cluster die 3, which concentrates the lines extracted from a plurality of extraction bobbins 2 wound with lines; and a bow-shaped flywheel 4, which can rotate around a rotating shaft 41; and a cradle 10 , which is arranged in the rotation area A of the flywheel 4 .

[0035] The flywheel 4 is supported by a frame (not shown) so as to be rotatable about a rotation sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com