Methods for operating valves

A solenoid valve and driver technology, applied in the valve operation/release device, valve device, valve details, etc., can solve the problems of noise increase, fluid column deceleration, etc., and achieve the effect of reducing closing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

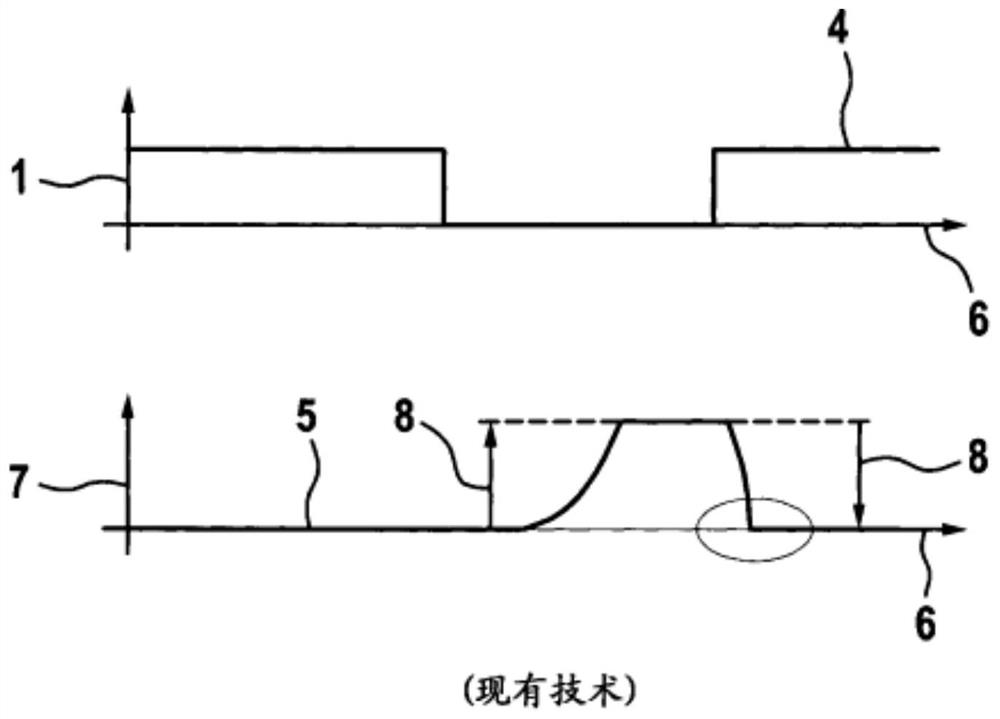

[0032] figure 1 A (ideal) current variation curve 4 having a subordinate (ideal) valve position change curve 5 is shown schematically in accordance with the prior art. According to according to figure 1 The schematic is plotted at the upper portion to the change curve of time 6 with respect to time 6, and the valve position 7 is plotted with the change curve of time 6. As can be seen in terms of the change curve of the valve position 7, the valve is completely closed at the height of the abscissa. For further describing figure 1 The current change curve 4 and the valve position variation curve 5, reference to the above embodiments of the prior art.

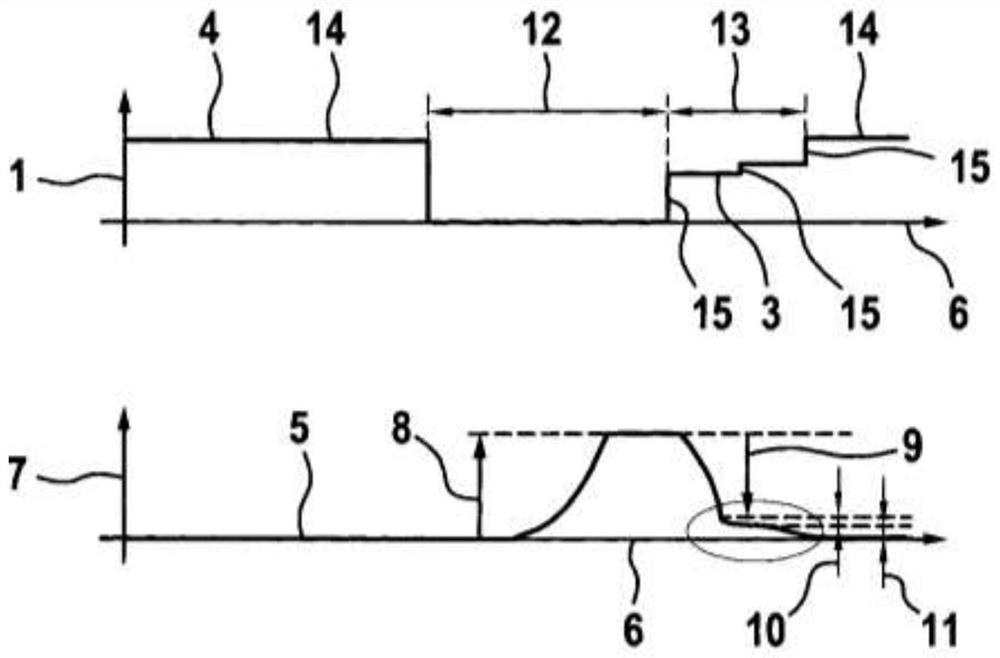

[0033] figure 2 The (ideal) current variation curve 4 having a (idealized) valve position change curve 5 produced in the method according to the invention is shown. Also according to according to figure 2 The schematic is plotted at the upper portion to the change curve of time 6 with respect to time 6, and the valve position 7 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com