High-pressure tank and manufacturing method thereof

A manufacturing method and technology of high-pressure tanks, applied in the field of high-pressure tanks, can solve problems such as heavy weight of high-pressure tanks, thickness of high-pressure tanks, unfavorable light weight, etc., and achieve the effects of increasing bearing strength, ensuring bearing strength, and overcoming defects of poor strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

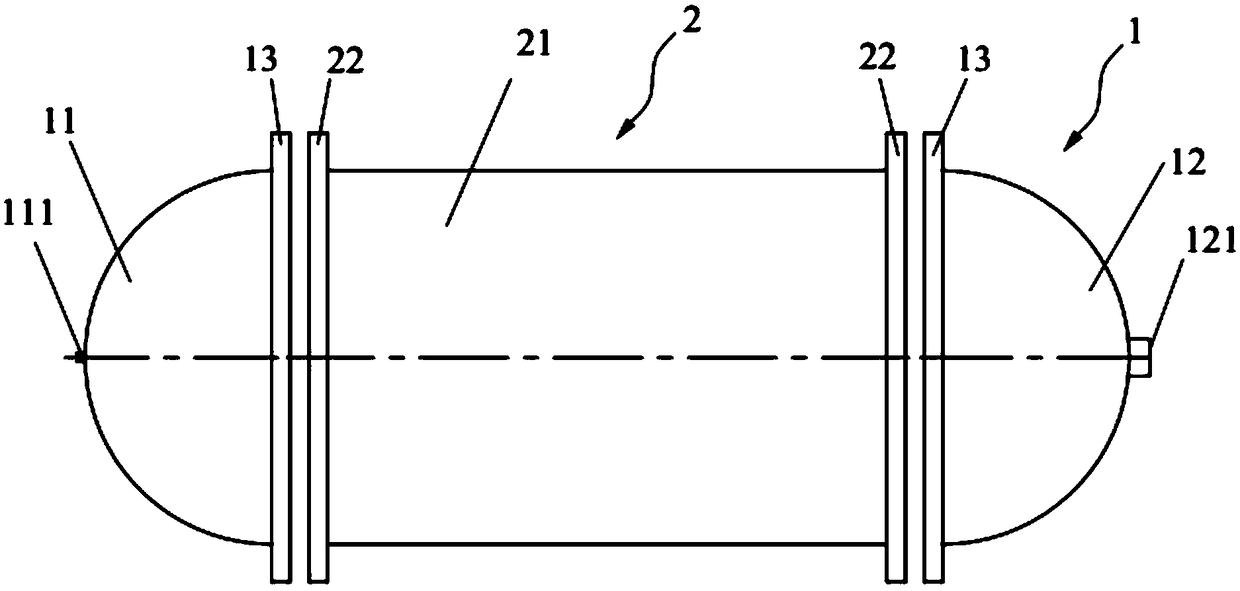

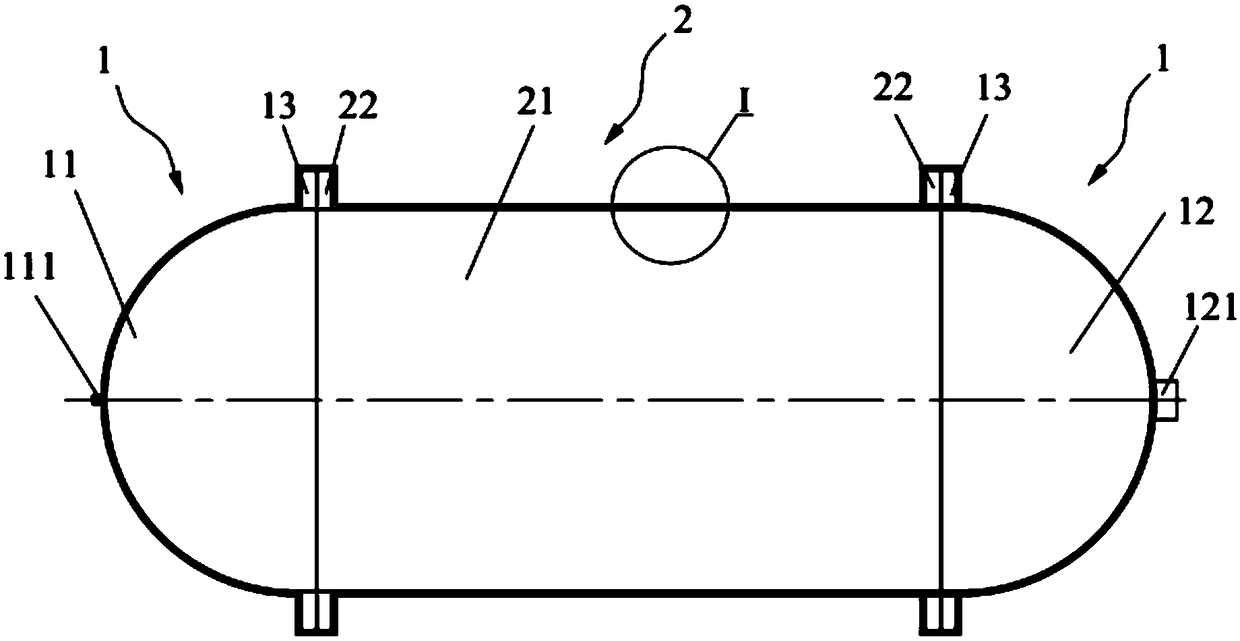

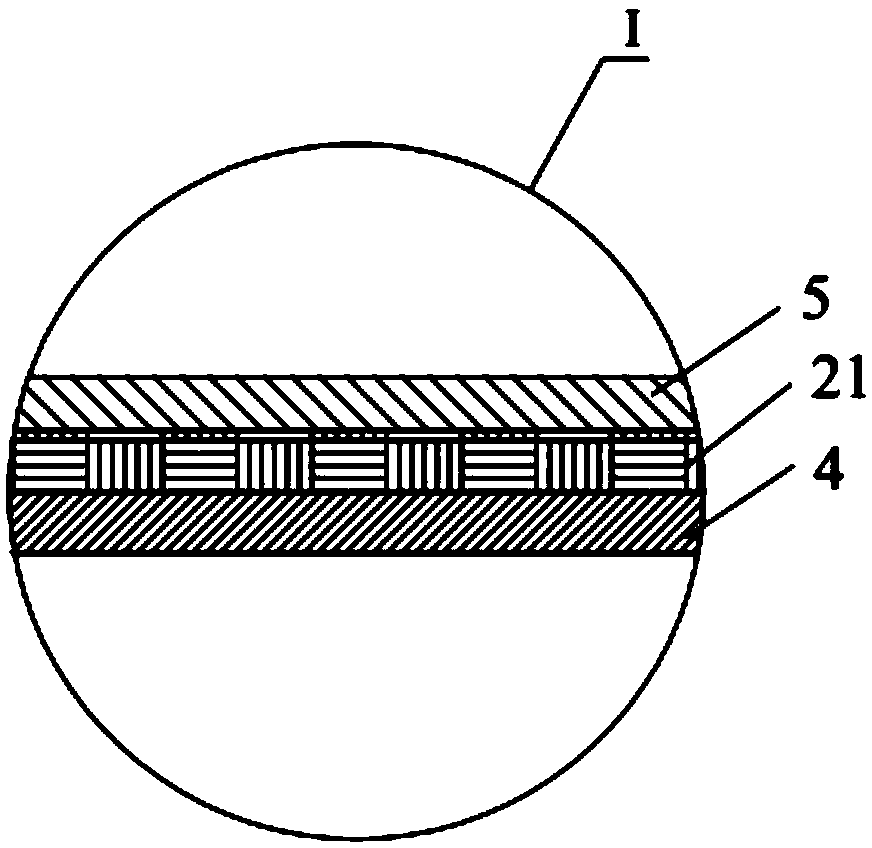

[0049] This embodiment provides a high-pressure tank, such as Figure 1-3 As shown, the high-pressure tank includes: an end cover assembly 1, a tank body 2, a plurality of bolts 3 and a fiber reinforced layer 5, the end cover assembly 1 includes an end cover body and an end cover flange 13; the tank body 2 includes a tank body 21 and two tank flanges 22 respectively arranged at both ends of the tank body 21, and the tank flange 22 is connected to the end cover flange 13; a plurality of bolts 3 are installed on the tank flange 22 and the end cover flange 13, used to connect the end cover assembly 1 and the tank body 2; the fiber reinforcement layer 5 can strengthen the above-mentioned multiple bolt connections. The fiber reinforced layer 5 increases the pressure bearing strength of the tank body fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com