Spiral pure steam tank

A pure steam and spiral technology, applied in steam boilers, steam generation, steam boiler accessories, etc., can solve the problems of complex steam tank structure, poor steam separation effect, large volume, etc., and achieve good steam separation effect, small space, steam high purity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described now in conjunction with accompanying drawing.

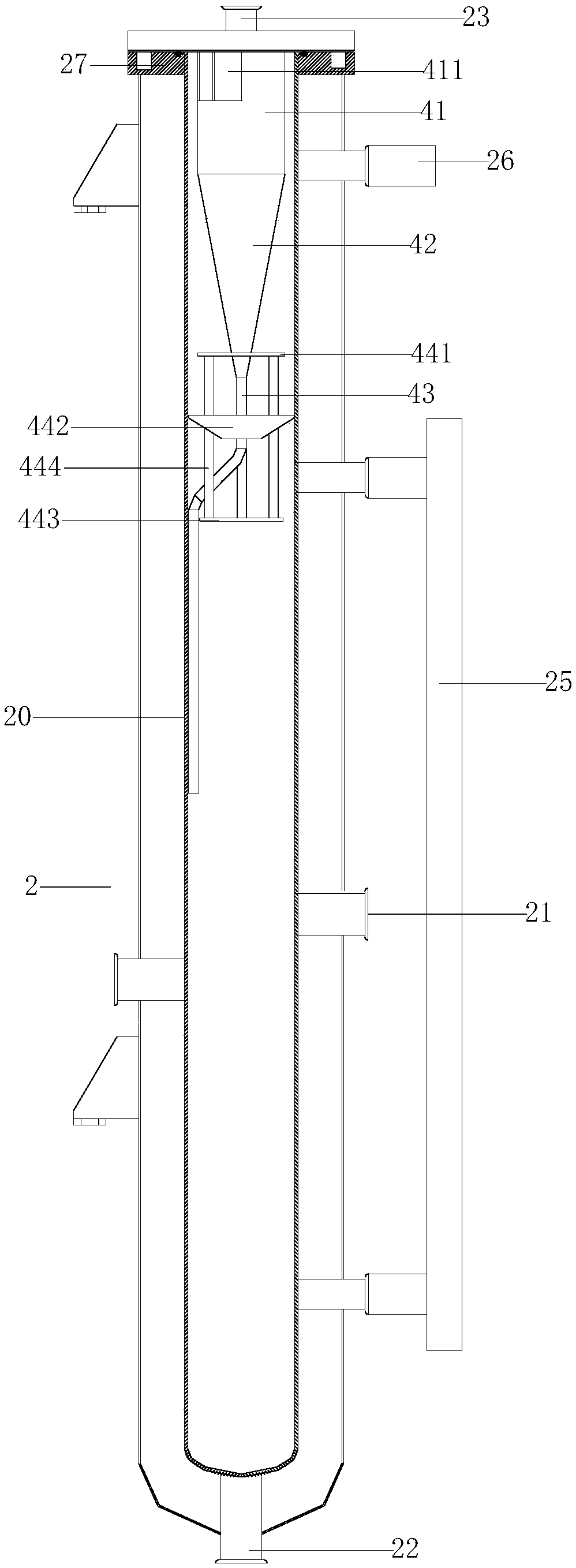

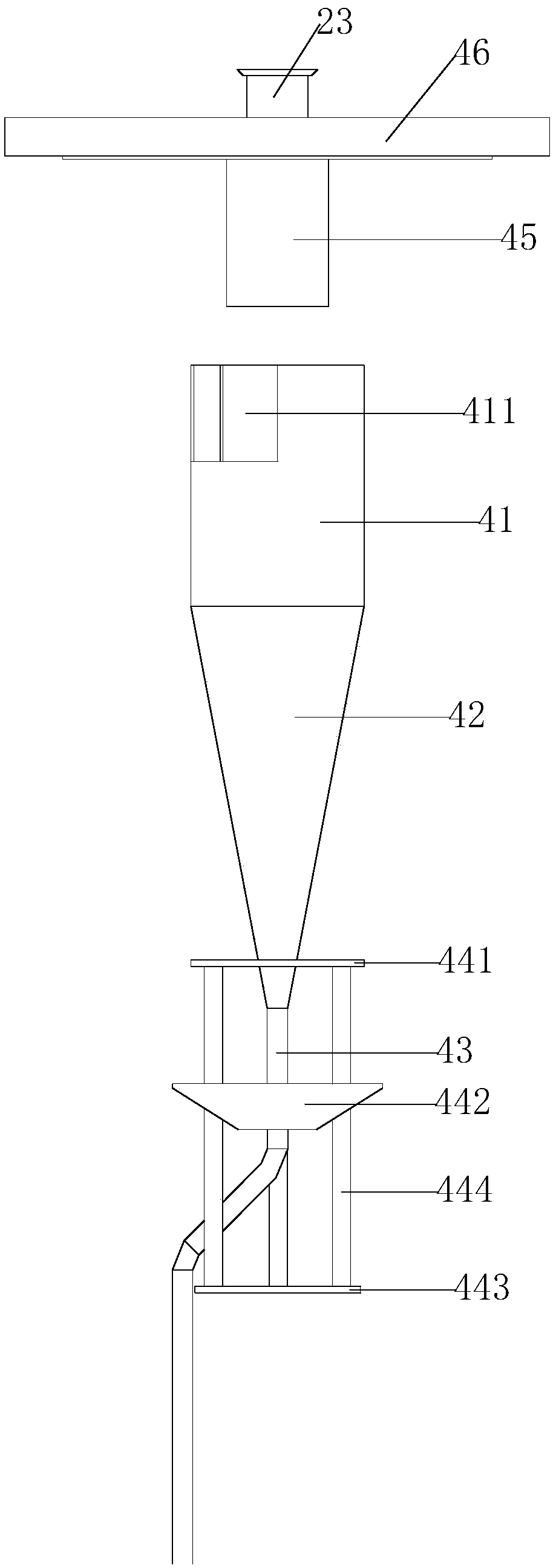

[0035] Such as Figure 1 to Figure 4 As shown, a spiral pure steam tank 2 includes a tank body 20, the tank body 20 is a vertical tank, the bottom of the tank body 20 is provided with a circulating water outlet 22, the top is provided with an opening, and a flange 27 is installed. The side of the tank body 20 is provided with a circulating water inlet 21, the side of the tank body 20 is also provided with a glass liquid level gauge 25 and a safety valve 26, the safety valve 26 is located at the top of the tank body 20, and the outer surface of the tank body 20 is provided with an insulating layer .

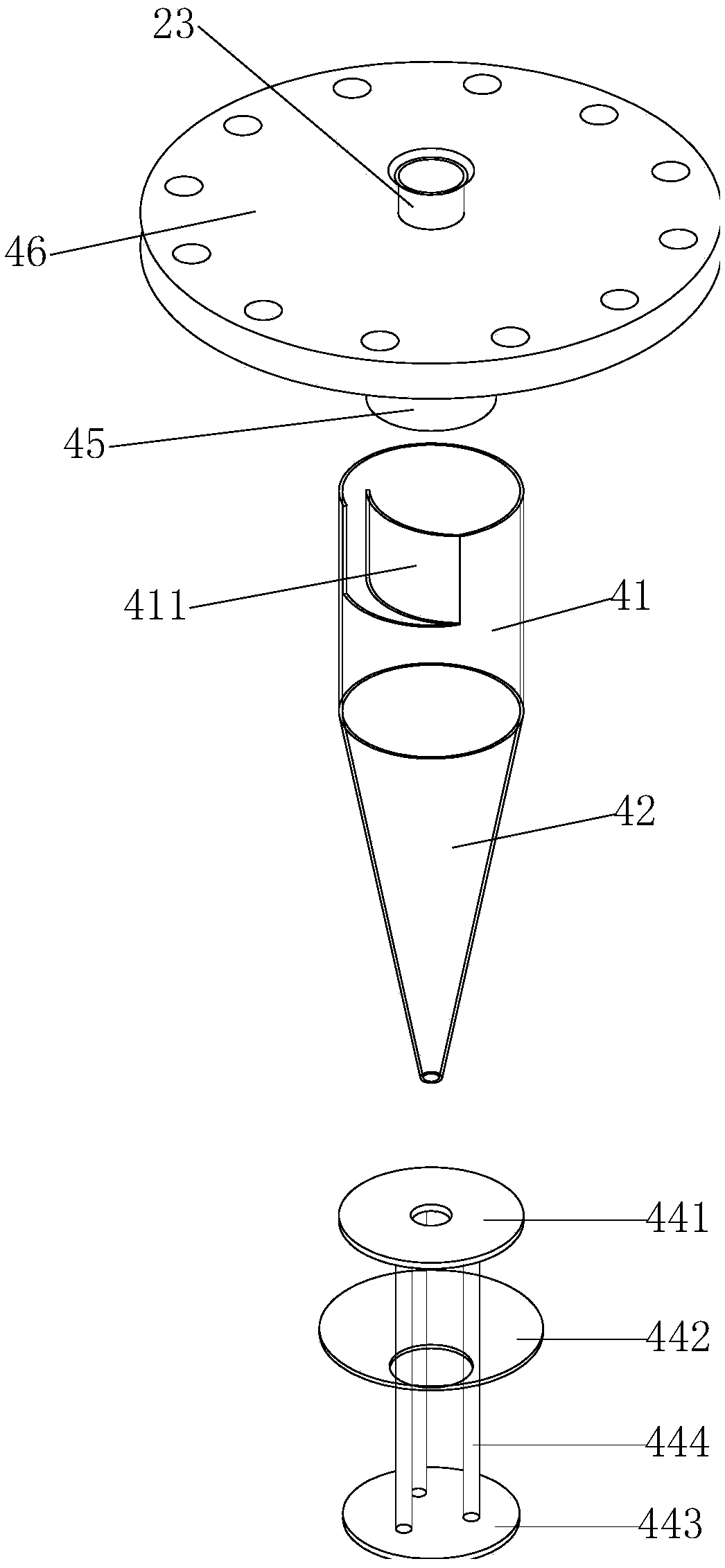

[0036] Also comprise gas-liquid separation device, the gas-liquid separation device is installed in the inside of tank body 20, and is positioned at the top of tank body 20, and gas-liquid separation device comprises separation cylinder 41 and conical cylinder 42, and conical cy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com