Efficient and stable integrated solidification and drying system

A high-efficiency, curing furnace technology, applied in the direction of drying, drying machine, progressive drying machine, etc., can solve the problems that the drying and curing effect cannot be guaranteed, the setting of the curing area is unreasonable, and the product quality cannot be guaranteed. Good tightening force, good curing effect, and the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

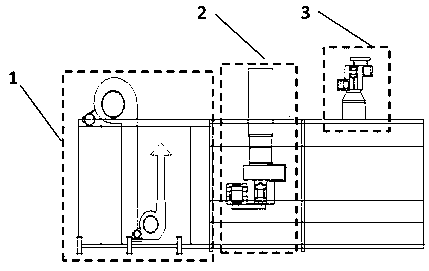

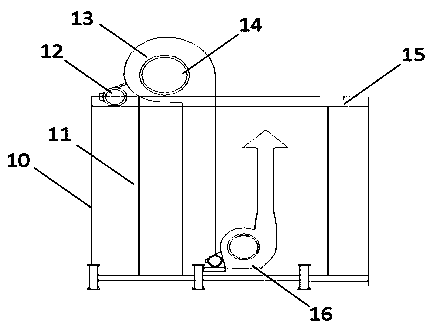

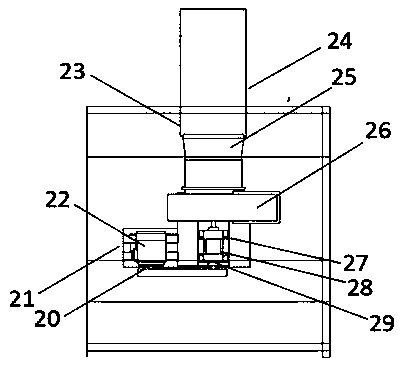

[0021] figure 1 For the efficient and stable integrated drying and curing system diagram of this patent, figure 2 It is the main body of the drying and curing furnace; image 3 It is the mesh belt transmission department; Figure 4 It is a hot air circulation and control system. figure 1 It is composed of drying and curing furnace body 1, mesh belt conveying part 2, hot air circulation and control system 3.

[0022] Further, the drying and curing furnace body 2 includes a furnace body 10, a drying section 11, a circulating air duct 13, a dehumidification channel 16, and a furnace body insulation board 15, and the number of drying sections 11 in the drying and curing furnace body 2 is 8. The number of air ducts is 4 sets, and the circulating air volume is 27600m 3 / h, the circulating air duct 13 is equipped with a filter screen 12 and an air valve 14, the material of the dehumidification channel is 304 stainless steel, the thickness of the insulation board 15 is 120mm, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com