Ultra-thin heat tube capillary structure and preparation method thereof

A technology of capillary structure and manufacturing method, which is applied in the field of heat transfer, can solve problems such as complex manufacturing process and poor capillary structure performance, and achieve the effect of increasing the number of vaporization cores, increasing the critical heat flow rate, and increasing the degree of vaporization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

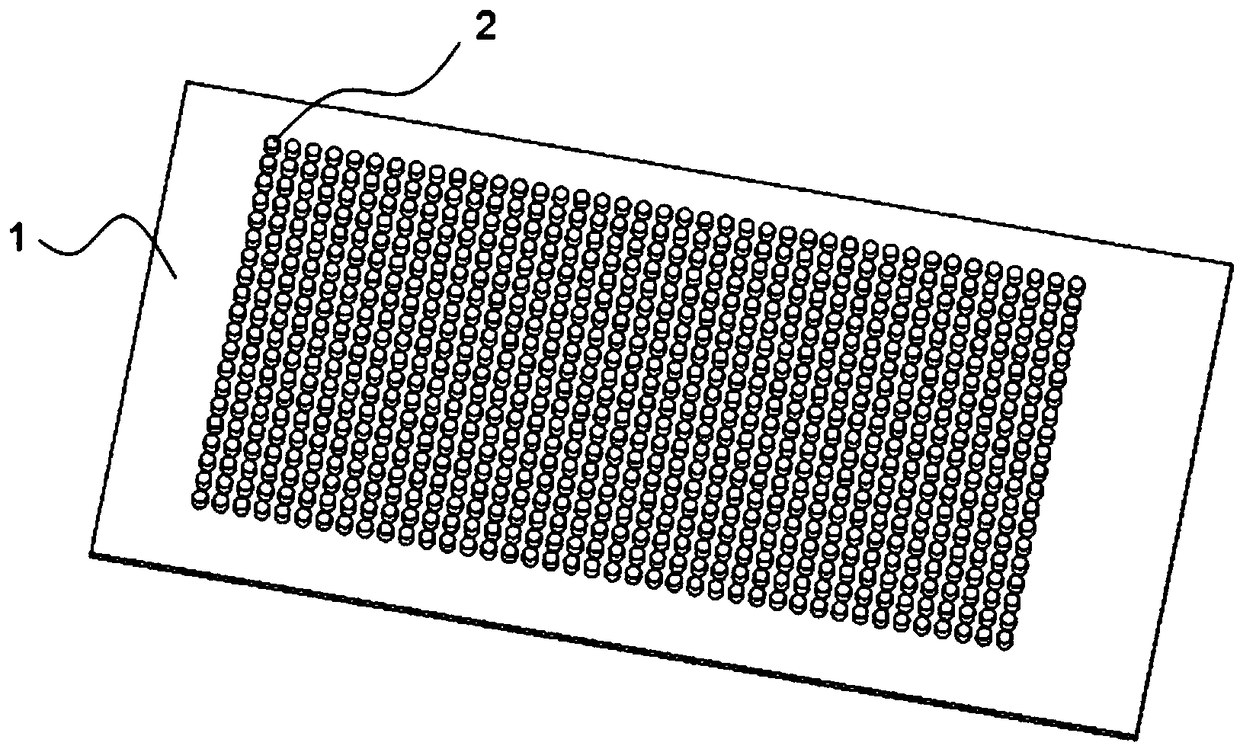

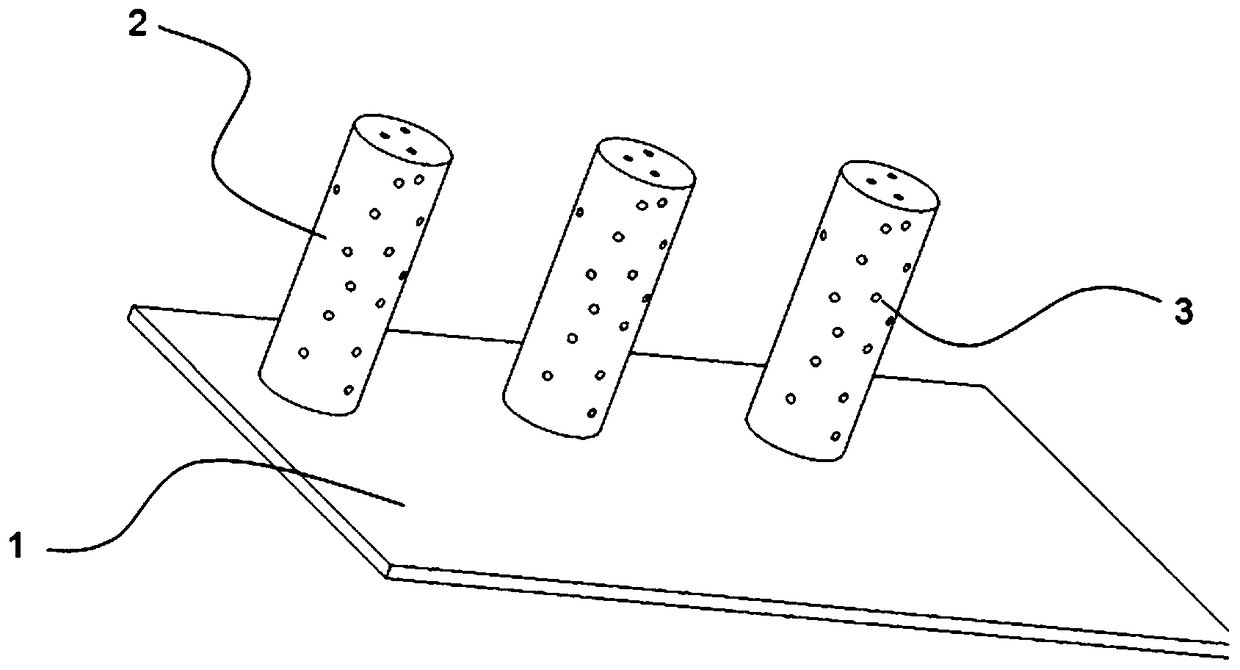

[0024] combine Figure 1-2 , the heat pipe capillary structure of the present invention includes a copper foil substrate 1 and a copper microcolumn array 2 arranged on the copper foil substrate 1, wherein the surface of the copper microcolumn array 2 has a micro or / and nanoscale porous structure 3 . Wherein, the micro-copper pillar array 2 is composed of cylindrical copper pillars arranged in a rectangular array with a diameter of 40 μm, a pitch of 20 μm, and a height of 50 μm.

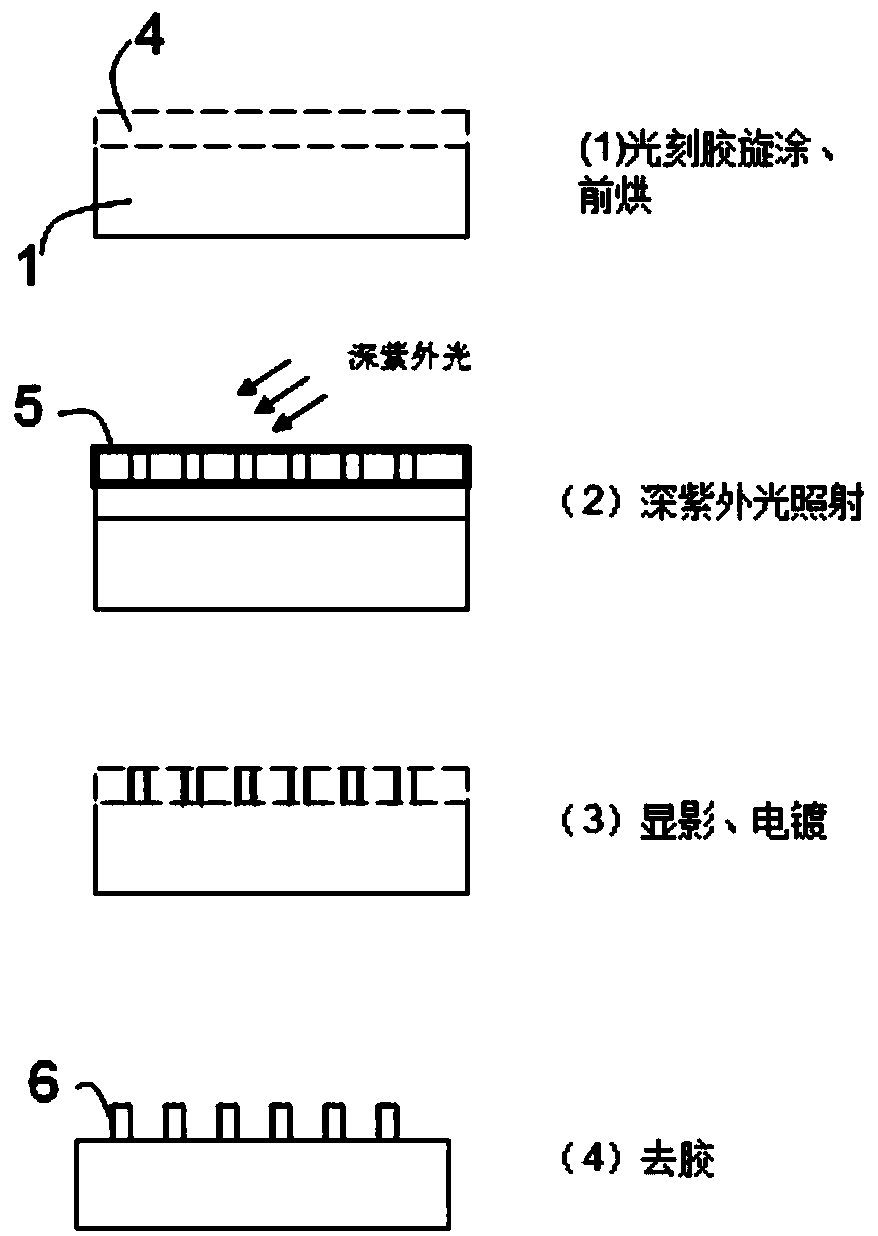

[0025] combine Figure 3-4 , the preparation process of the heat pipe capillary structure of the present invention is as follows:

[0026] (1) Selection of substrate

[0027] In this embodiment, a copper foil with a thickness of 100 μm is selected as the substrate.

[0028] (2) Photolithography process

[0029] First put the copper foil substrate 1 into an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com