A Gas Chromatographic Separation Simulation Method Based on Stochastic Diffusion Theory

A technology of gas chromatography separation and simulation method, which is applied in computational theoretical chemistry, design optimization/simulation, special data processing applications, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

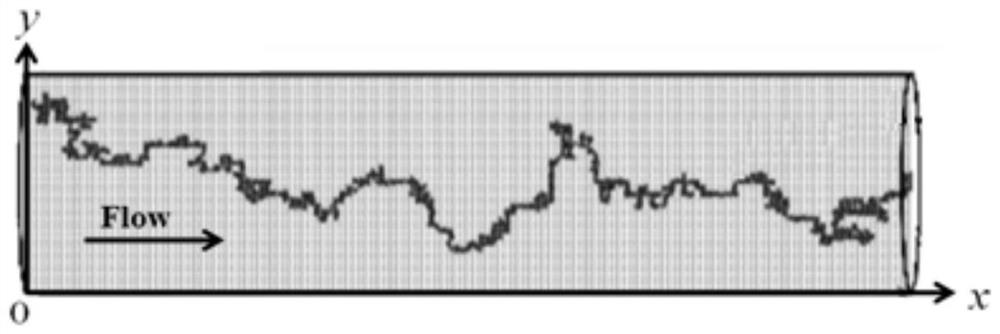

Method used

Image

Examples

Embodiment 1

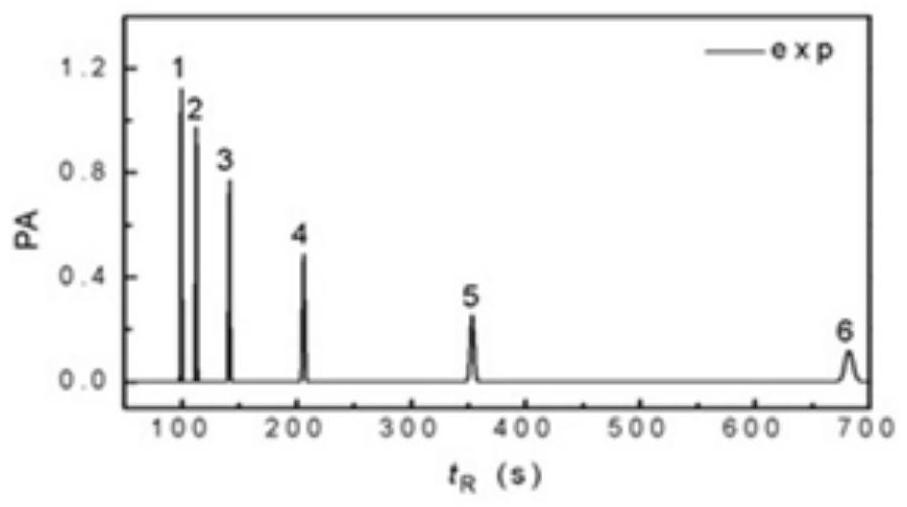

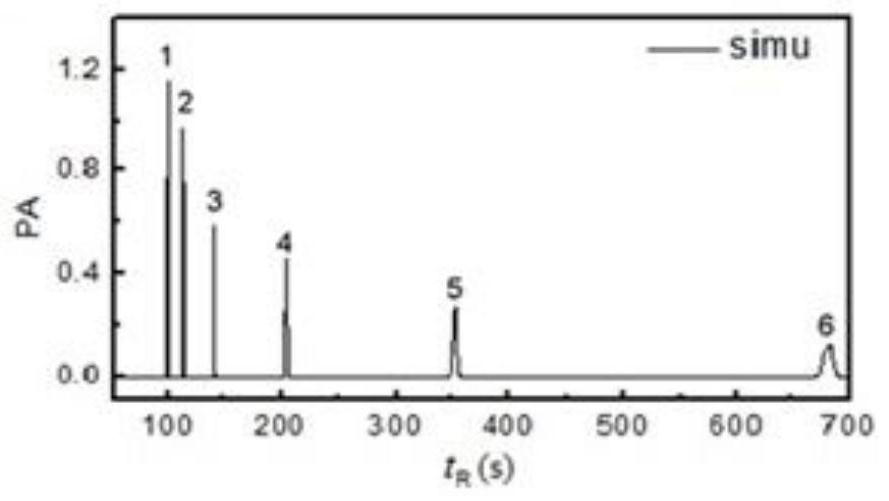

[0034] Example 1: Separation simulation of n-pentyne, n-hexyne, n-heptyne, n-octyne, n-nonyne and n-decyne mixture by packed-column gas-liquid chromatography

[0035] The substance to be separated is a mixture of n-pentyne, n-hexyne, n-heptyne, n-octyne, n-nonyne and n-decyne. Take 0.1 mL of each substance to prepare a mixed sample. The carrier gas is high-purity nitrogen (99.999% purity), and the FID is the detector. The carrier gas flow rate is 0.5mL / min, and the makeup flow rate is 24mL / min -1 , the air flow rate is 300mL / min, the hydrogen flow rate is 30mL / min, the gasification chamber temperature is 433K, the detector temperature is 433K, the column temperature is 333K, the split ratio is 1:80, and the injection volume is 0.2μL.

[0036] The particle numbers of n-pentyne, n-hexyne, n-heptyne, n-octyne, n-nonyne and n-decyne are all 100, and the random diffusion behavior of the above 600 particles is simulated in the space filled by the spherical energy barrier. The tem...

Embodiment 2

[0041] Example 2: Separation simulation of a mixture of n-pentane, n-hexane, n-heptane, n-octane, n-nonane and n-decane by capillary column gas-solid chromatography

[0042] The substance to be separated is a mixture of n-pentane, n-hexane, n-heptane, n-octane, n-nonane and n-decane. Take 0.1 mL of each substance to prepare a mixed sample. The carrier gas is high-purity nitrogen (99.999% purity), and the FID is the detector. The carrier gas flow rate is 0.5mL / min, and the makeup flow rate is 24mL / min -1 , the air flow rate is 300mL / min, the hydrogen flow rate is 30mL / min, the gasification chamber temperature is 433K, the detector temperature is 433K, the column temperature is 333K, the split ratio is 1:80, and the injection volume is 0.2μL.

[0043] The particle numbers of n-pentane, n-hexane, n-heptane, n-octane, n-nonane, and n-decane were set to 100, respectively, and the random diffusion behavior simulation of the above 600 particles was carried out in the space with no ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com