220-grade enameled copper round wire for automobile starting motor

A car start-up, enamelled copper technology, applied in the direction of circuits, insulated cables, electrical components, etc., can solve the problems of uneven thickness of enameled wire paint film, high cost of car start-up motors, poor insulation performance stability, etc., so that it is not easy to peel off, Good for coil winding and good insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

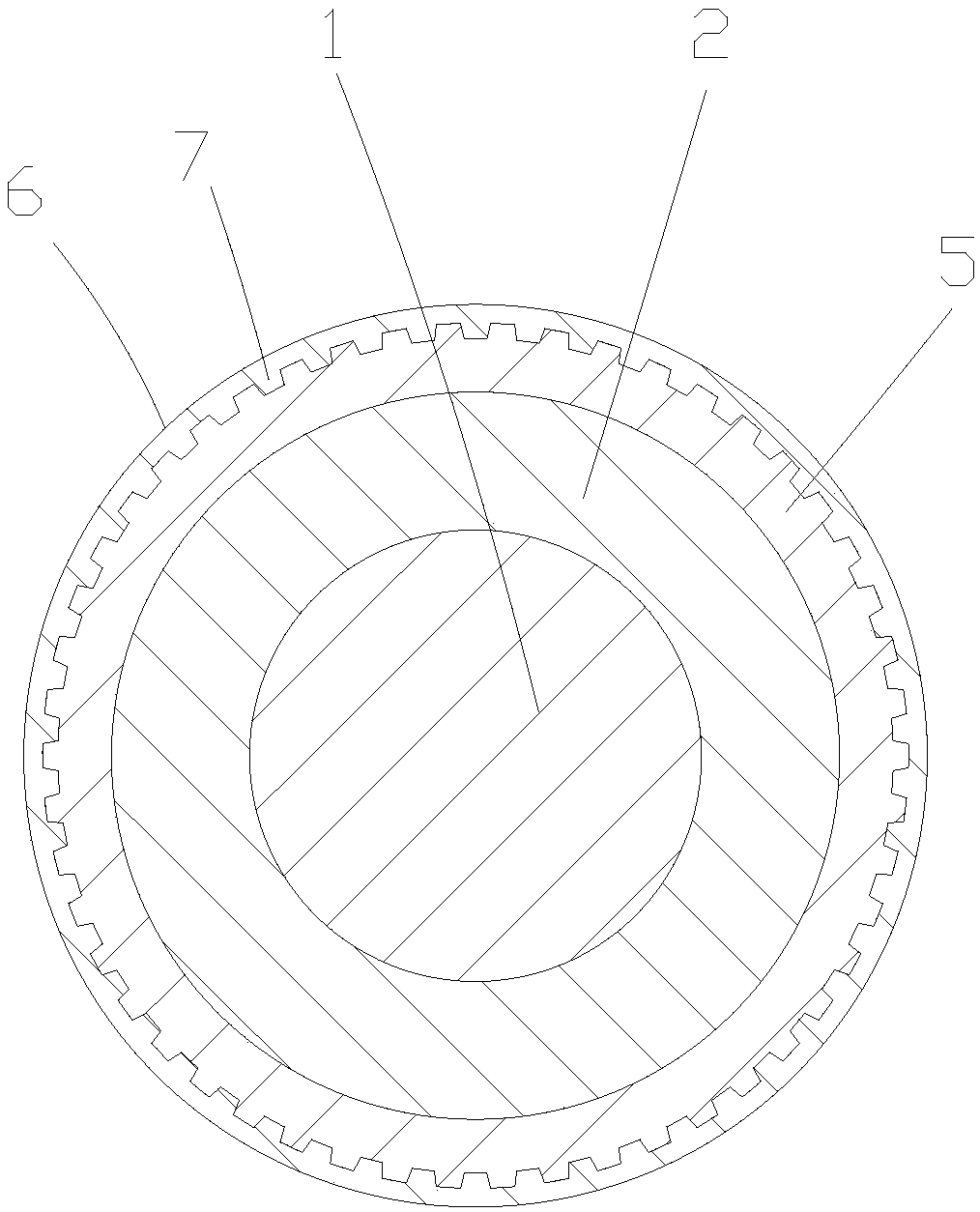

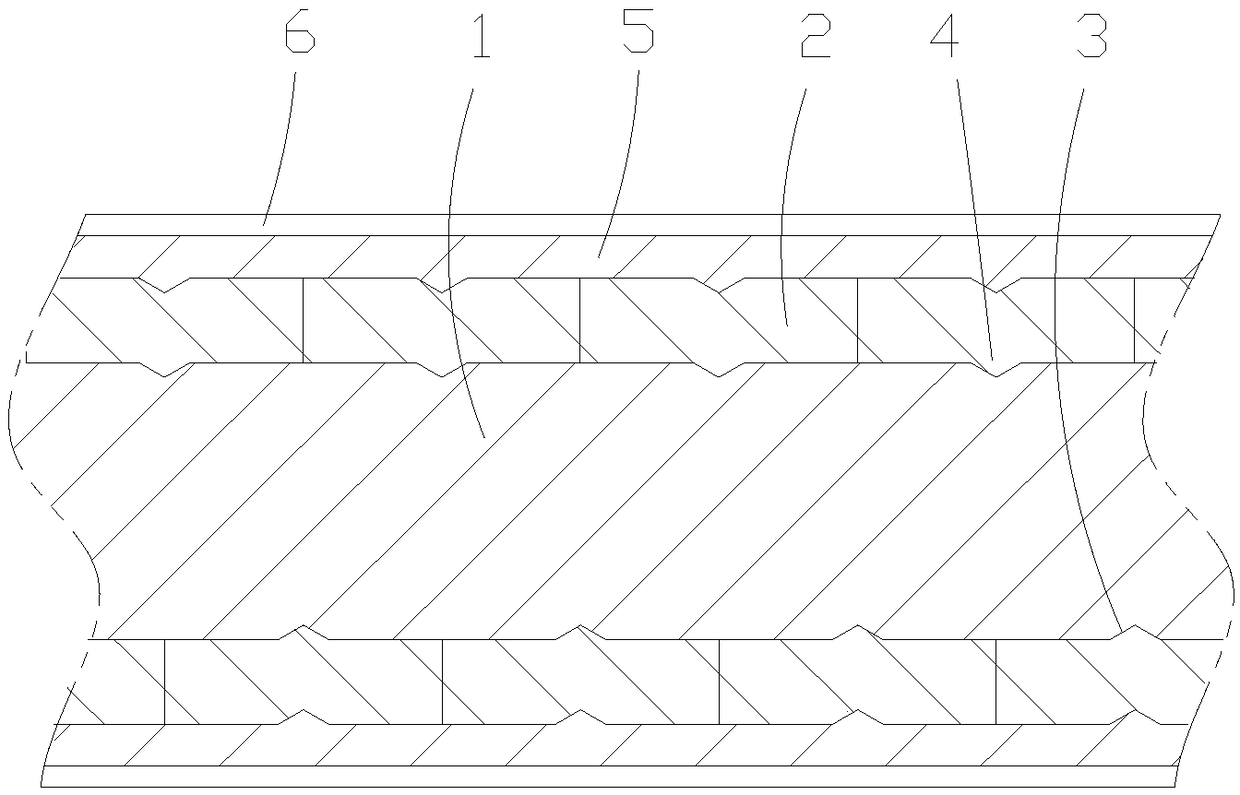

[0015] Example. Grade 220 enamelled round copper wire for automobile starter motors, such as figure 1 and figure 2 As shown, it includes a silica gel strip 1, a flat aluminum strip 2 is spirally wound on the silica gel strip 1, the outer surface of the flat aluminum strip 2 is provided with a tooth groove 3 extending along the helical direction of the flat aluminum strip 2, and the inner surface of the flat aluminum strip 2 A toothed belt 4 extending along the helical direction of the flat aluminum strip 2 is provided on the top, and a copper layer 5 that engages with the tooth groove 3 is provided on the helical surface of the flat aluminum strip 2 , and a plurality of paint hanging grooves 7 are opened on the outer surface of the copper layer 5 , the outer surface of the copper layer 5 is coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com