Portable Motor Coil Cutter

A portable and cutter technology, which is applied in the manufacture of motor generators, electromechanical devices, electrical components, etc., can solve the problems of increased maintenance costs, heavy physical exertion of maintenance personnel, and low maintenance efficiency, so as to reduce wear and avoid aggravated cleaning work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

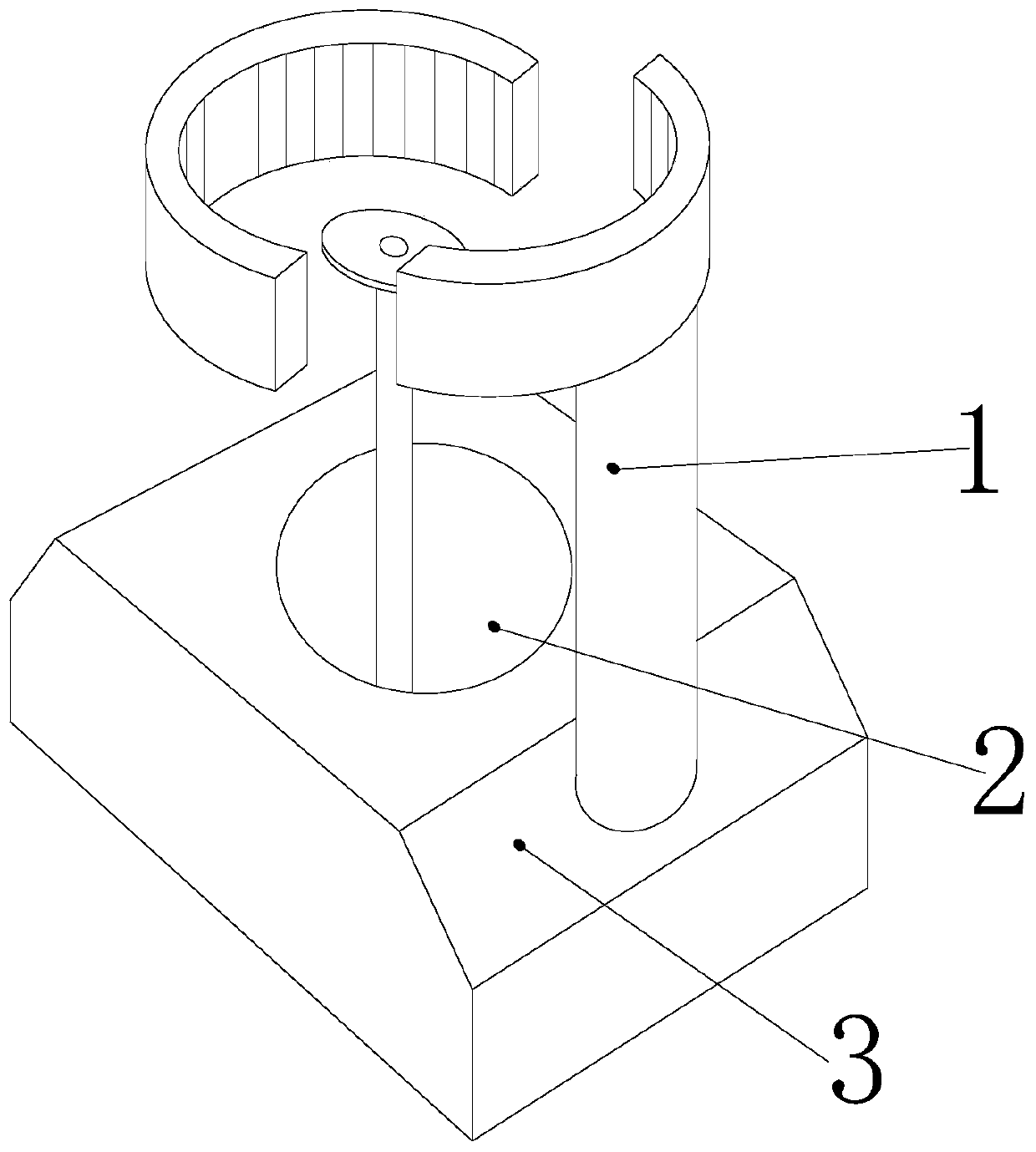

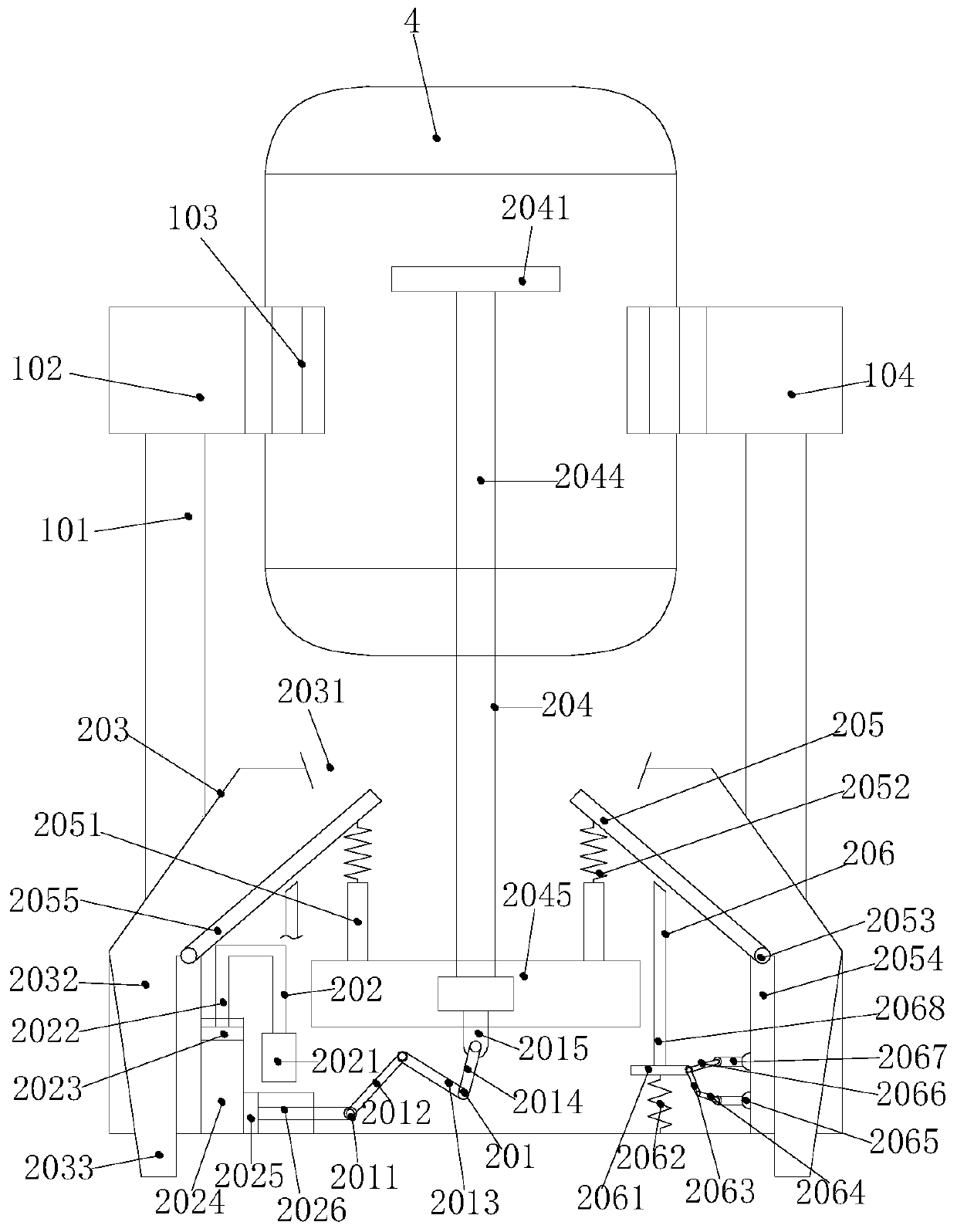

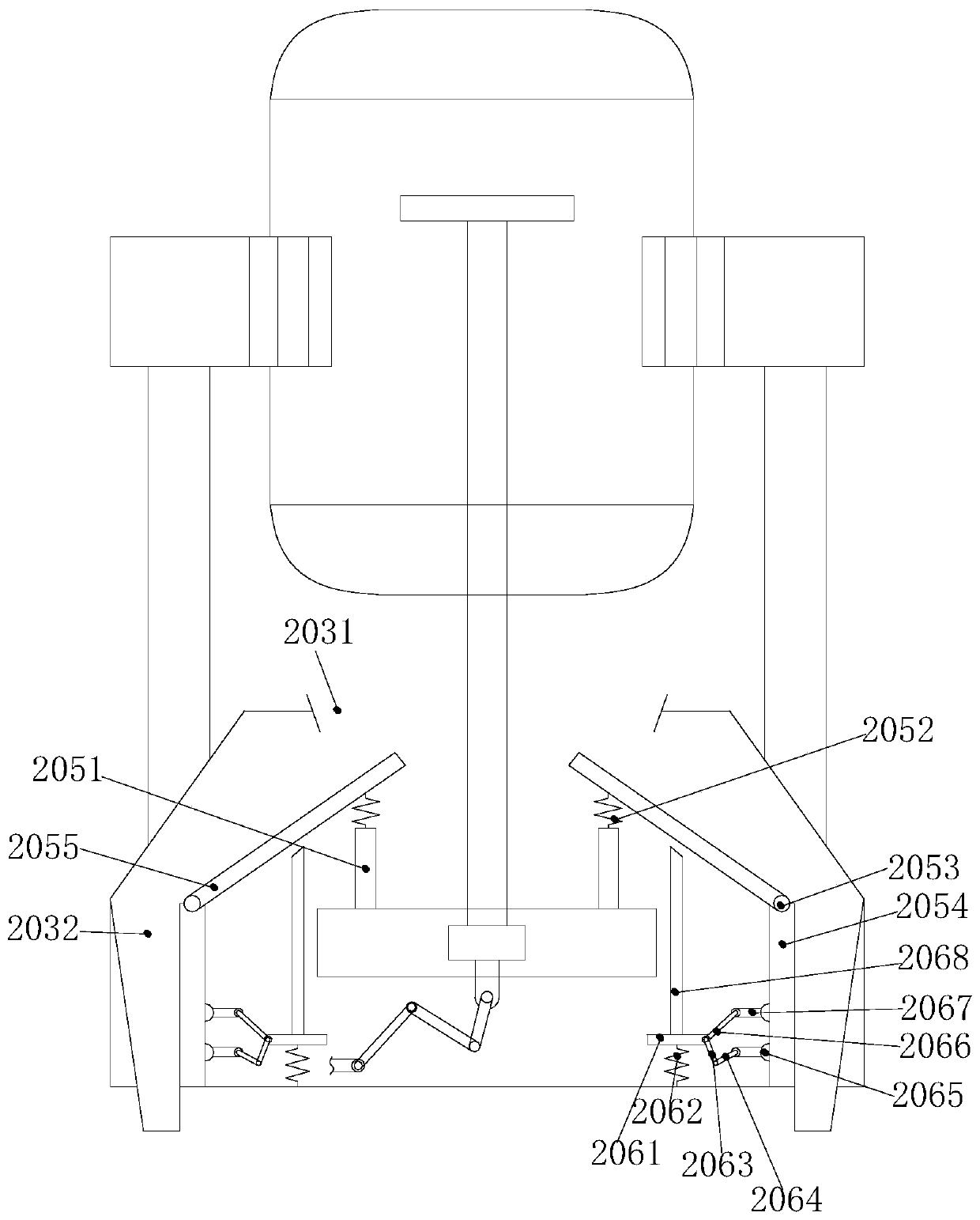

[0028] see Figure 1-Figure 5 , the present invention provides a portable motor coil cutter, its structure includes a motor fixing mechanism 1, a progressive cutting device 2, a fixed base 3, a motor 4, the motor fixing mechanism 1 is mechanically connected to the motor 4, and the motor fixing mechanism 1 Installed on the fixed base 3 and mechanically welded with the fixed base 3, the fixed base 3 is provided with a progressive cutting device 2;

[0029] The progressive cutting device 2 is composed of a mechanical transmission mechanism 201, a cutting device driving mechanism 202, a slag conveying device 203, a cutting device 204, a slag shaking off mechanism 205, and a shock absorbing device 206;

[0030] The mechanical transmission mechanism 201 is mechanically connected with the cutting device driving mechanism 202, the cutting device driving mechanism 202 mechanically cooperates with the cutting device 204 through the mechanical transmission mechanism 201, and the debris s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com