Flexible containers with bottom support structure

A flexible container and bottom structure technology, applied in the field of flexible containers, can solve problems such as unsightly, difficult to distribute liquid products, expensive containers, etc., and achieve the effects of not easy to wear, cheap manufacturing, and low complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present disclosure describes various embodiments of containers made from flexible materials. Because these containers are made of flexible materials, these containers offer several advantages when compared to conventional rigid containers.

[0025] Although made of flexible materials, the container of the present disclosure can be constructed with sufficient structural integrity such that it can successfully receive, contain, and dispense the fluent product as intended. Also, these containers can be constructed with sufficient structural integrity such that they can successfully withstand external forces and environmental conditions from handling. Additionally, these containers can be constructed with a structure that allows them to be successfully displayed for sale and put into service as intended.

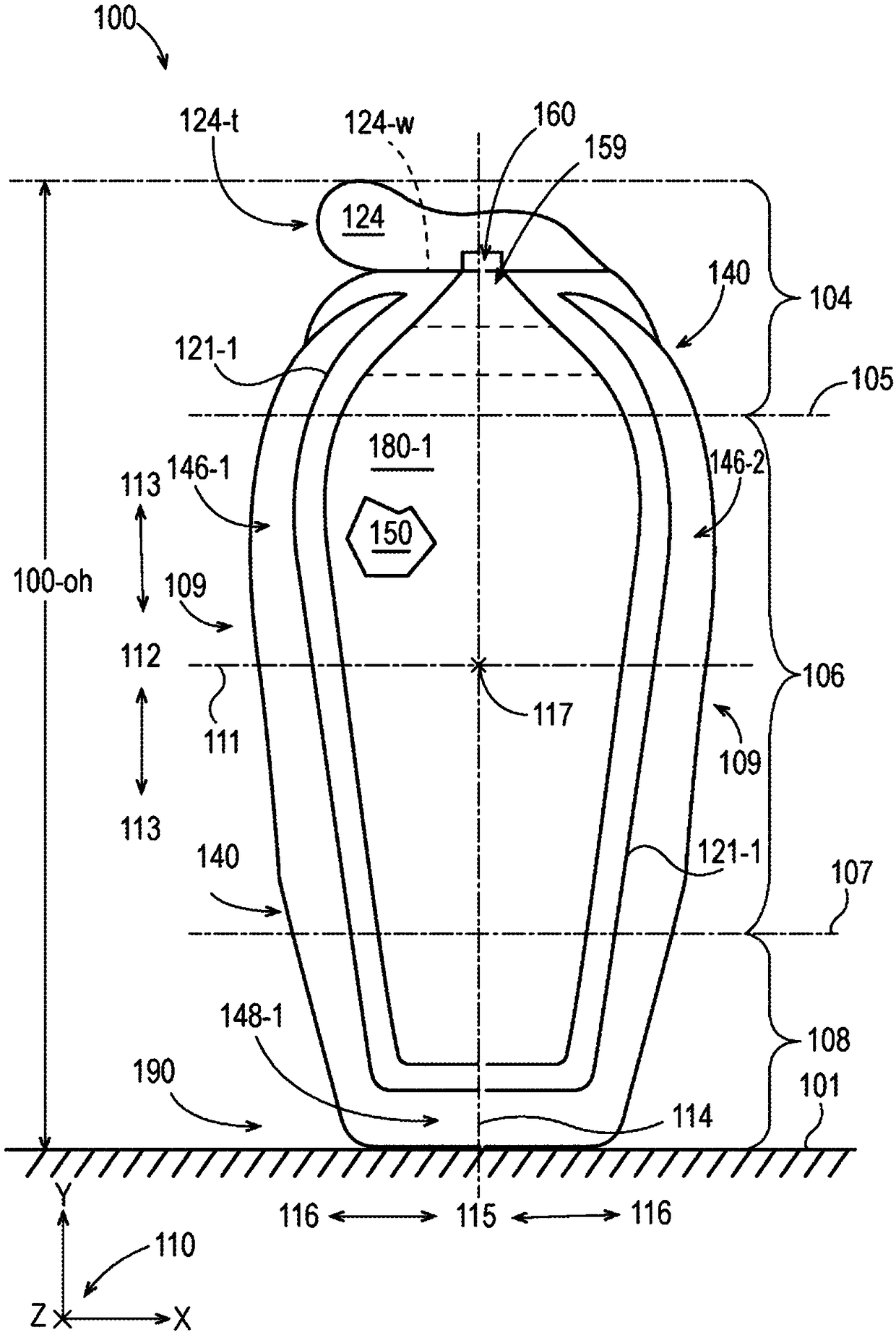

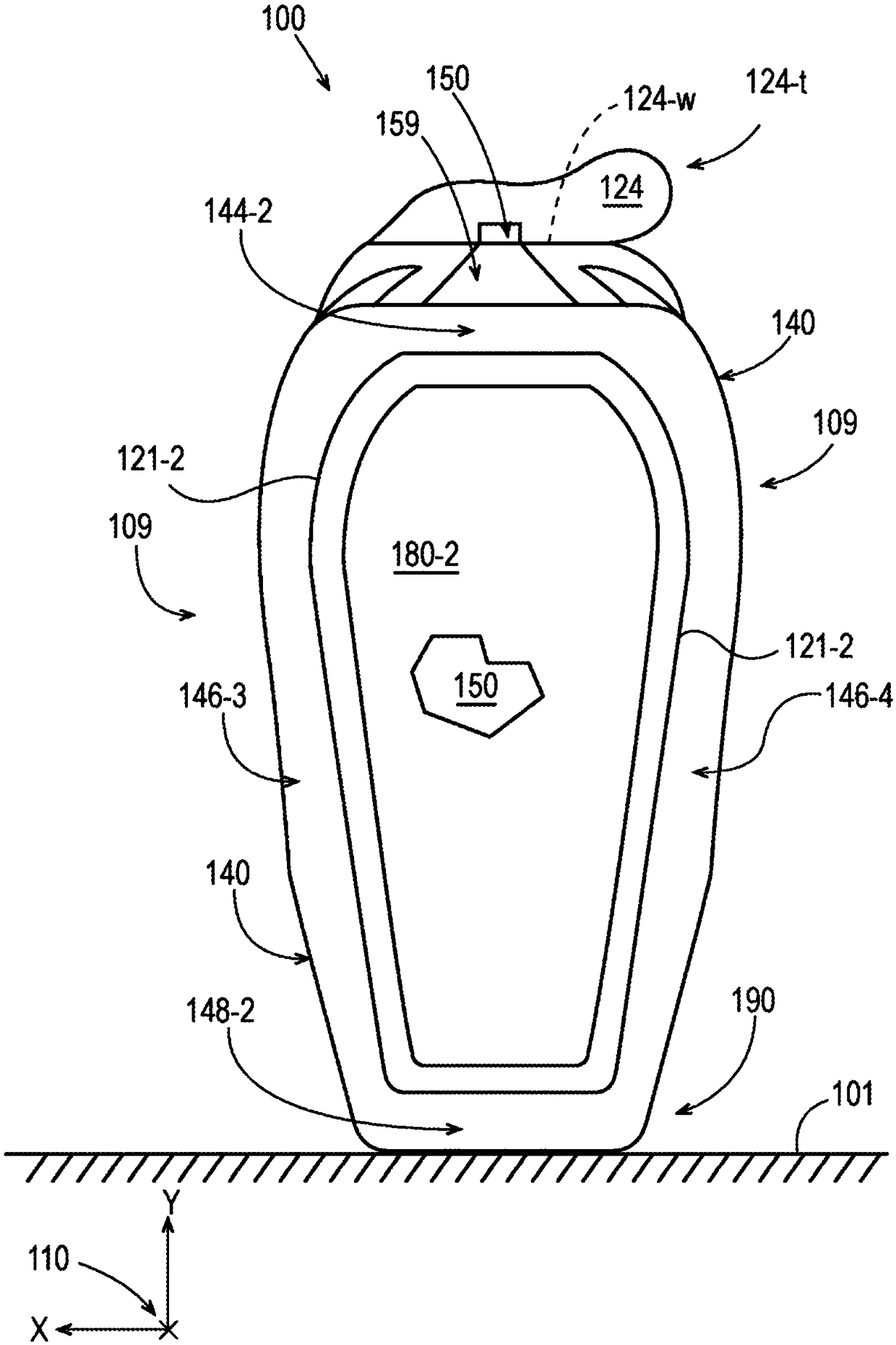

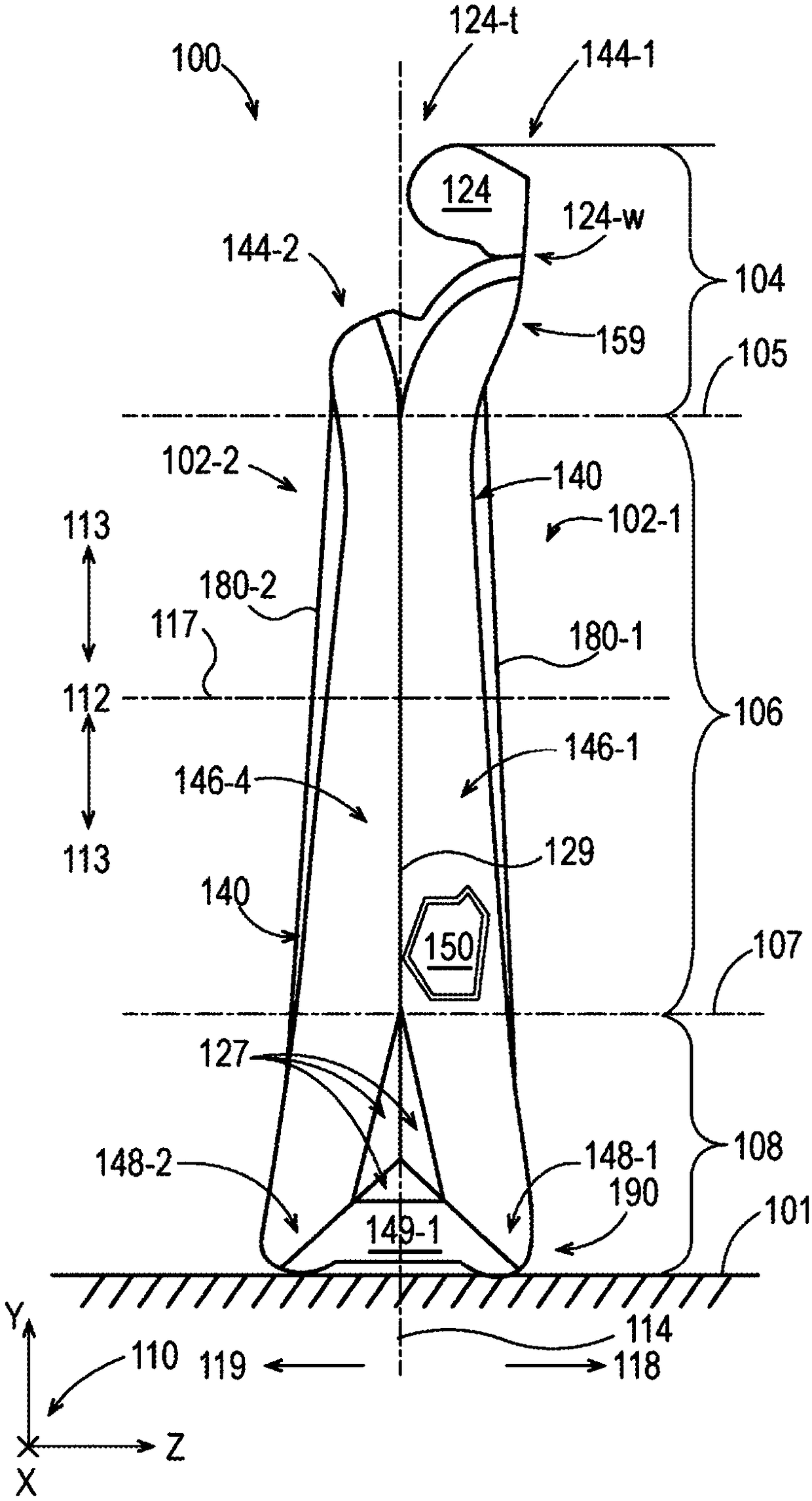

[0026] Figures 1A-1G Various views of one embodiment of a stand up flexible container 100 are shown. Figure 1A A front view of container 100 is shown. The contai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com