Plug-in connector with a heat capacity element arranged on a contact element

A technology of contact elements and connectors, applied in the direction of contact components, vehicle connectors, vehicle components, etc., which can solve the problems of increasing size, structural space requirements of contact element size, weight and cost constraints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

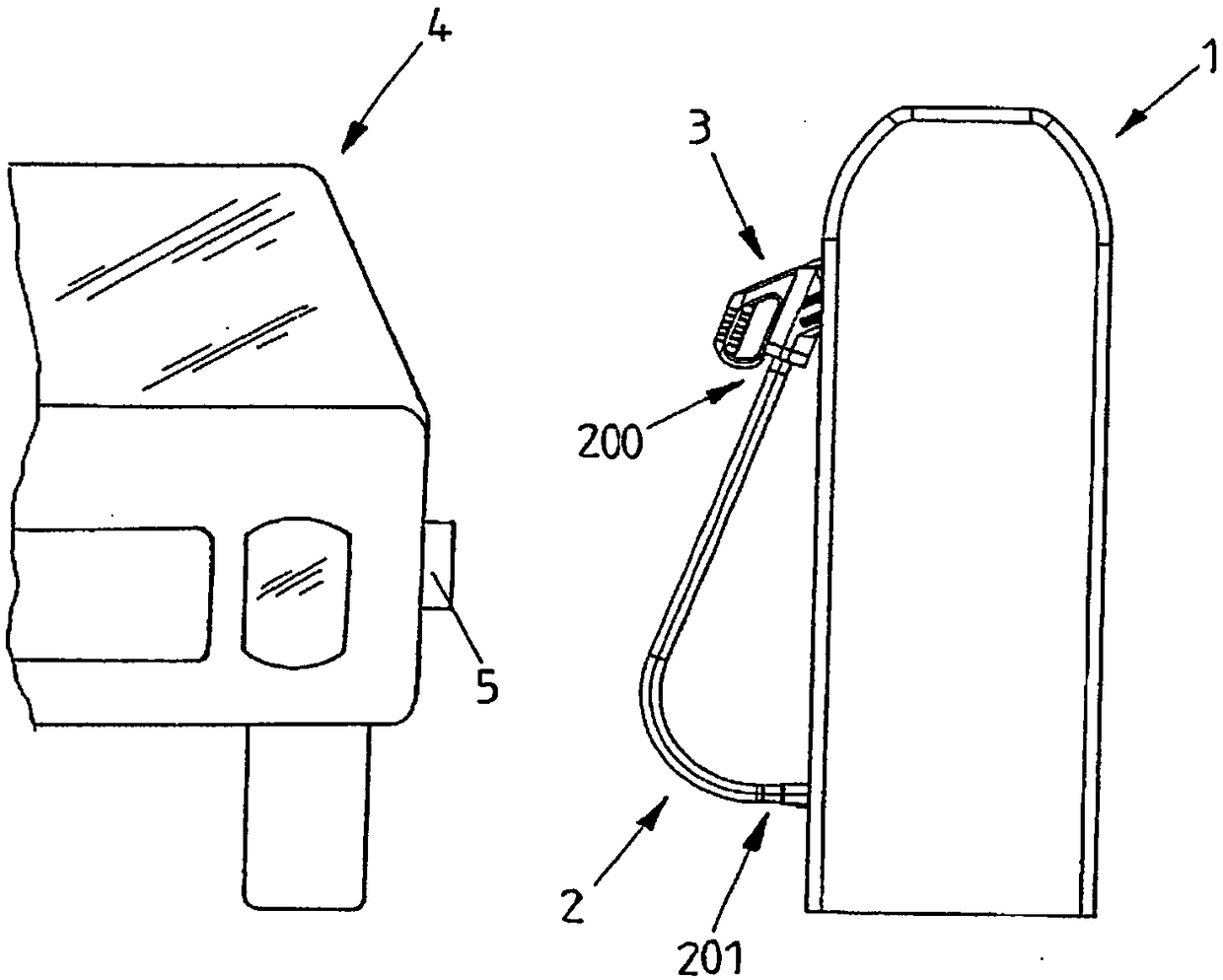

[0040] figure 1 A charging station 1 for charging an electrically driven vehicle 4 , also called an electric vehicle, is shown. The charging station 1 is suitable for providing charging current in the form of alternating current or direct current, and has a cable 2 connected to the charging station 1 at one end 201 and to a mating plug connector 3 in the form of a charging plug at the other end 200 .

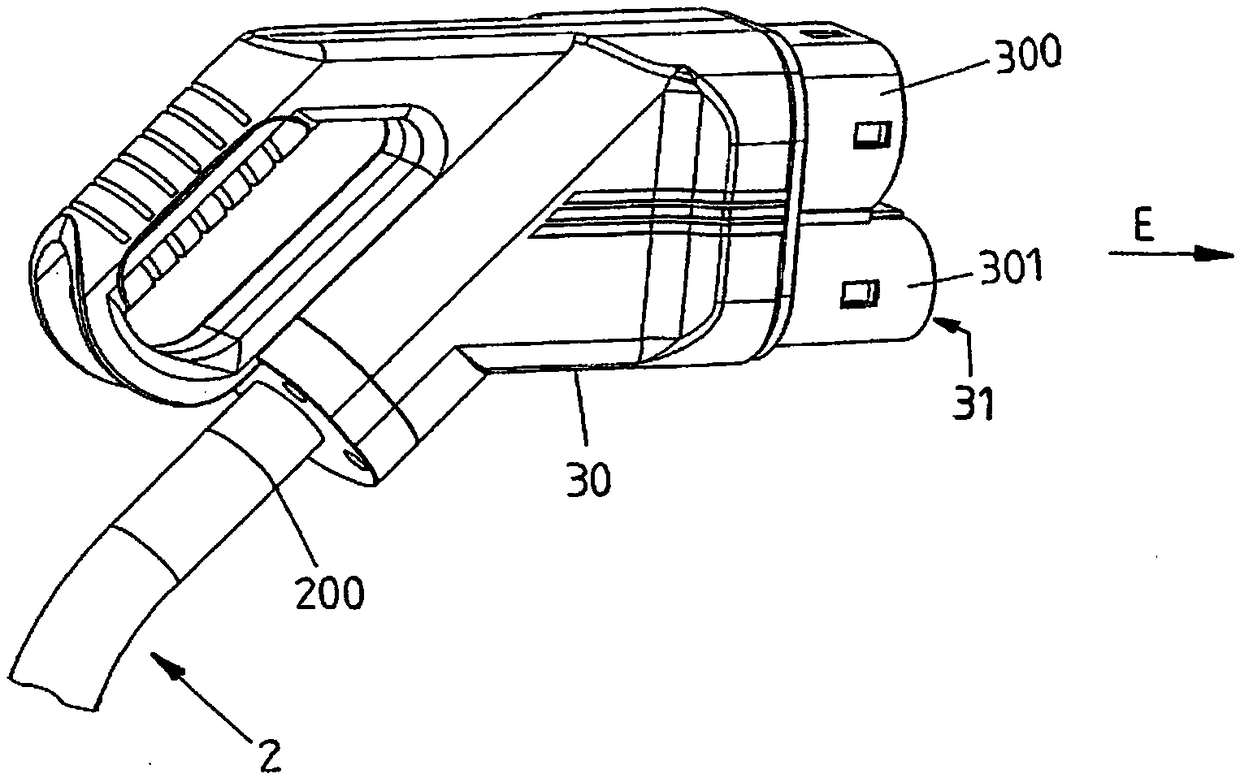

[0041] like figure 2As shown in the enlarged view of , the mating plug connector 3 has plug-in parts 300, 301 on the housing 30, which are used to make the mating plug connector 3 connect with the charging socket on the vehicle 4 in a plug-in manner. The associated plug-in connector 5 of the form snaps into place. In this way, the charging station 1 can be electrically connected to the vehicle 4 in order to conduct a charging current from the charging station 1 to the vehicle 4 .

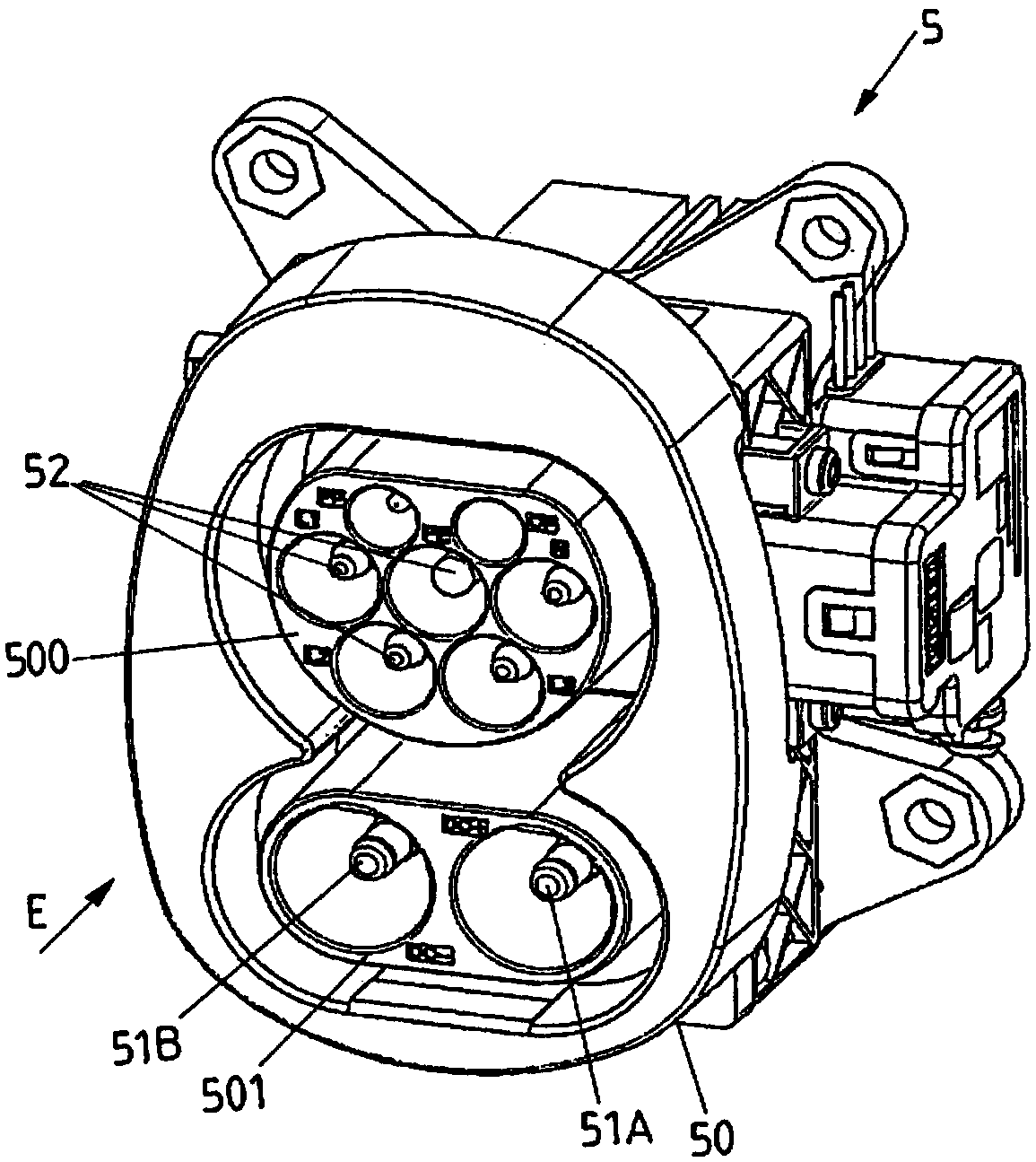

[0042] In order to realize fast charging of the electric vehicle 4 in the so-called fast charg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com