Motor and method of manufacturing the motor

A manufacturing method and motor technology, applied in the manufacture of motor generators, connection with control/drive circuits, electromechanical devices, etc., can solve the problems of increased motor assembly workload, difficult terminal module installation, etc., and achieve the effect of reducing assembly workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

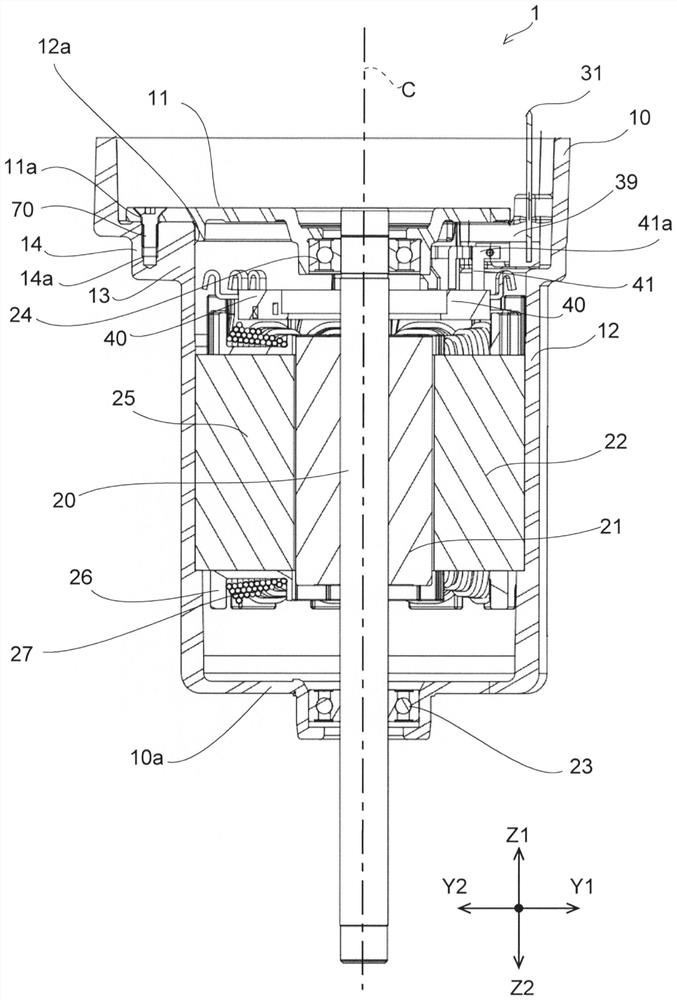

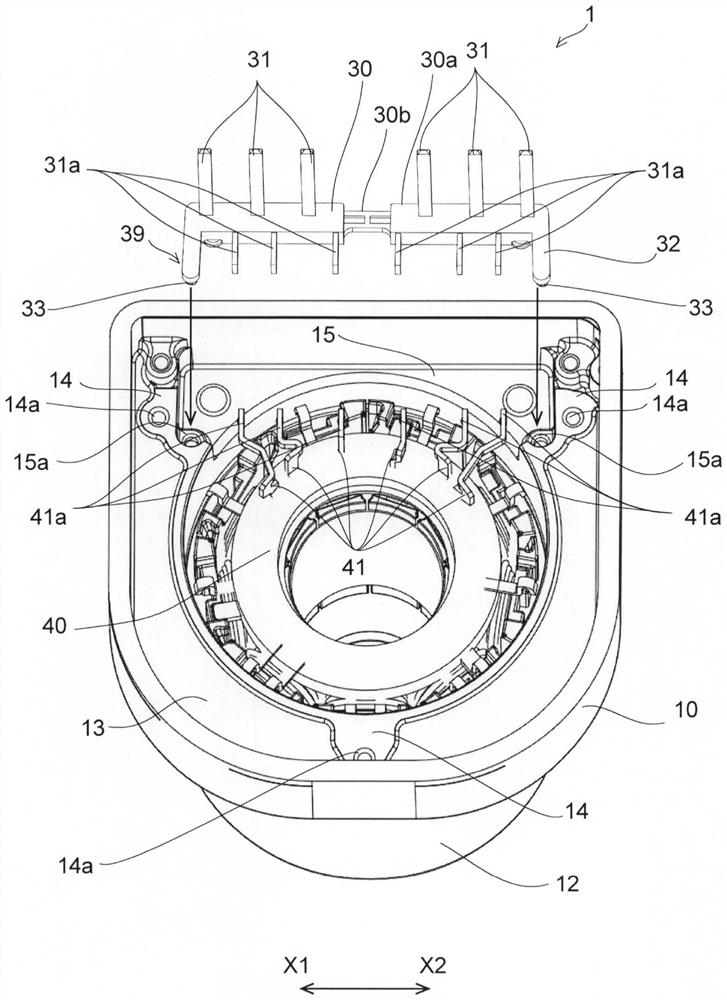

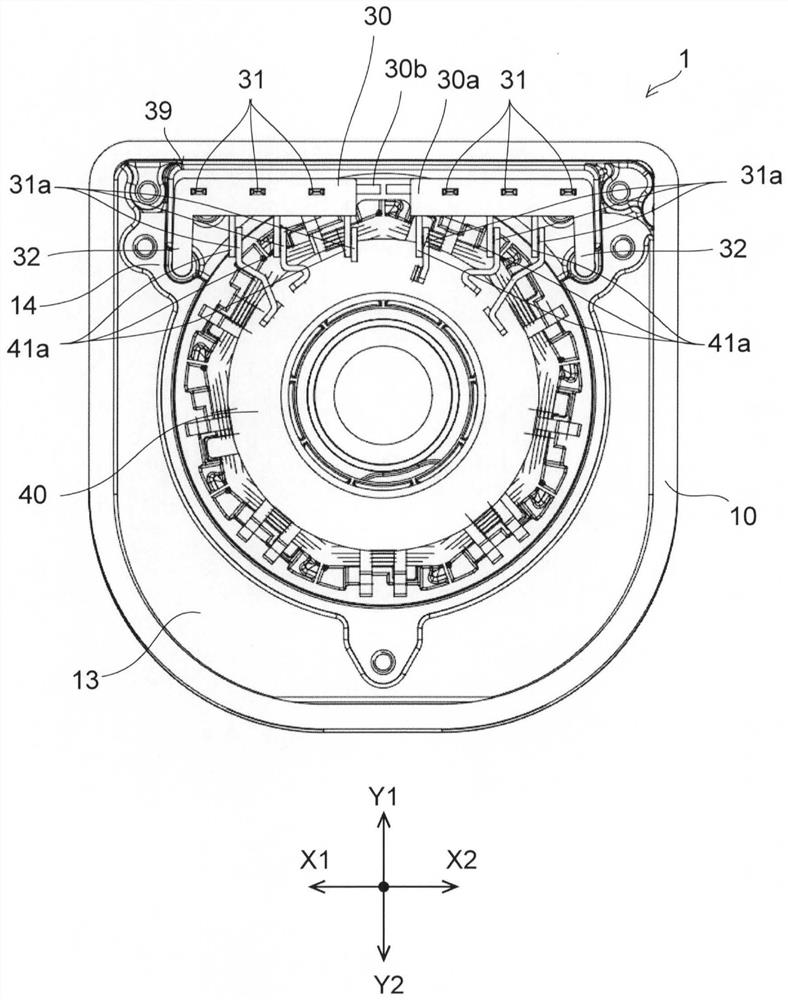

[0019] Below, while referring to the attached Figure 1 Exemplary embodiments of the present invention will be described in detail. Additionally, the figure 2 The direction in which the central axis C of the motor 1 extends is simply referred to as "axial direction", and the radial and circumferential directions centered on the central axis C of the motor 1 are simply referred to as "radial" and "circumferential". In addition, in Figure 4 In the plan view of the motor 1 viewed from the axial direction, the direction in which the front end of the bus bar connecting portion 41a extends is referred to as the “front-rear direction”, and the direction in which the plurality of bus bar connecting portions 41a are aligned is referred to as the “left-right direction”. The "axial direction", the "front-rear direction", and the "left-right direction" are perpendicular to each other. exist Figure 4 In the "left-right direction", when the terminal pin 31 is viewed from the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com