Manufacturing method and manufacturing apparatus for silicone rubber molded body

A manufacturing method and a manufacturing device technology, applied in the field of manufacturing silicone rubber moldings, capable of solving unsolvable problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

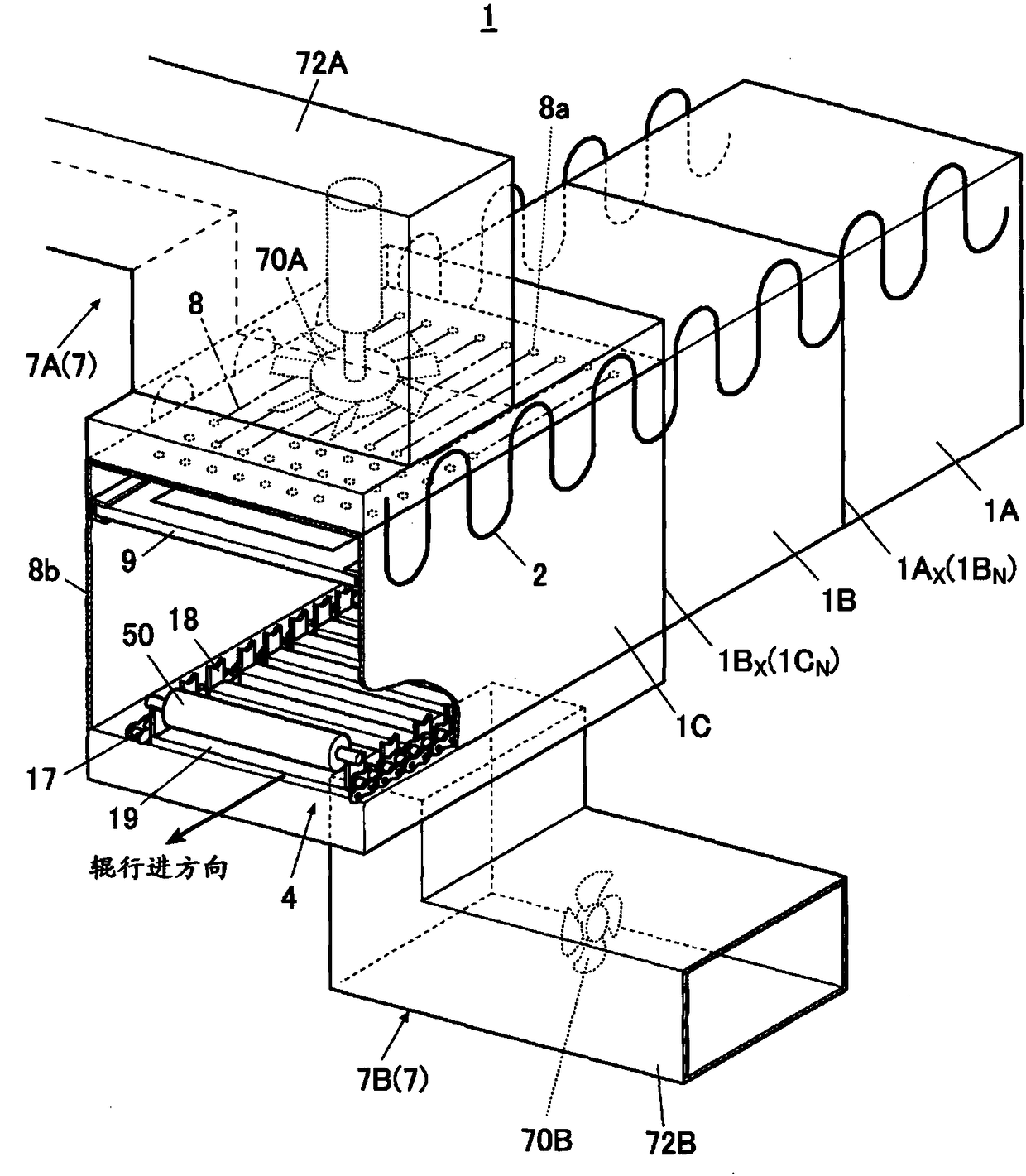

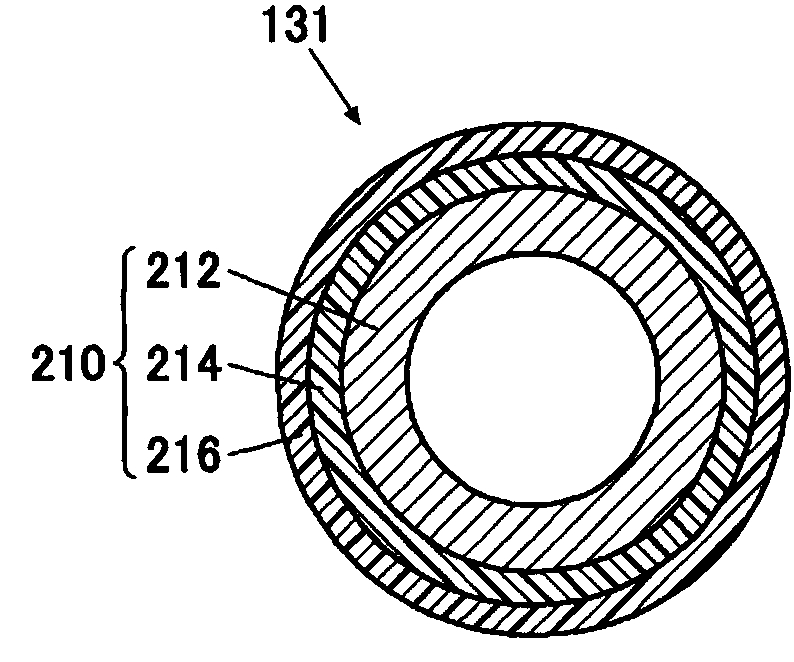

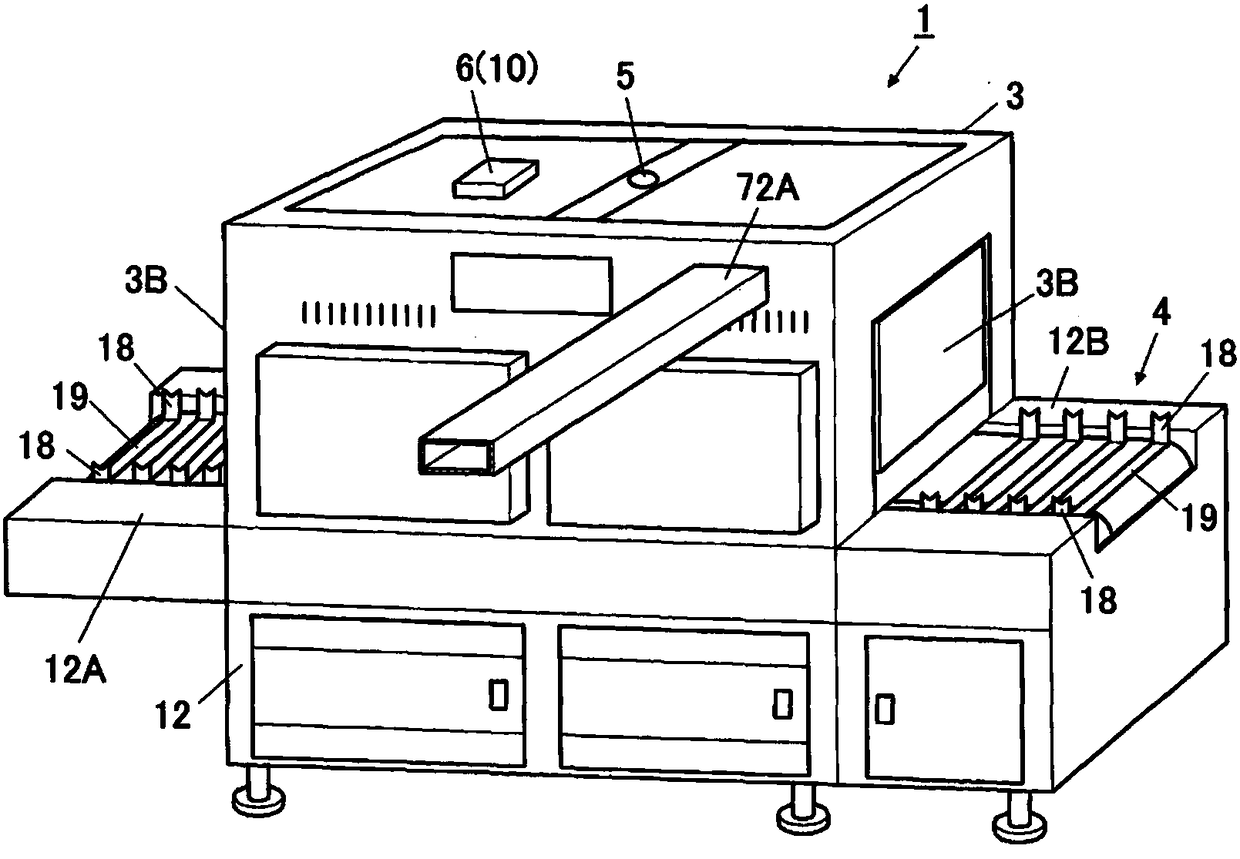

Method used

Image

Examples

Embodiment

[0197] Hereinafter, although an Example is given and this invention is demonstrated concretely, this invention is not limited to this. In addition, "part" or "%" used in an Example means "part by mass" or "% by mass" unless otherwise specified.

[0198] First, the preparation of the precursor of the silicone rubber molding is prepared. Next, the treatment of Examples 1 to 8 and Comparative Example 1 as a step of heating was performed on the precursor of the silicone rubber molded body. Regarding the specific processing of Examples 1 to 8 and Comparative Example 1, that is, whether to introduce and discharge ambient gas from the outside ("whether or not to introduce and discharge" in Table 1), the speed of introducing and discharging ambient gas (Table 1 "Introduction and discharge speed"), the type of ambient gas introduced, the type of gas, and the moisture content ("gas type" and "moisture content" in Table 1), the sum of the volume V of the precursor of the silicone rubber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com